Production of electrically conductive vehicle component

A technology for components and vehicles, applied in the assembly/disassembly of contacts, household components, household appliances, etc., can solve problems such as overheating and damage, and achieve the effect of easy manual operation and low manual operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

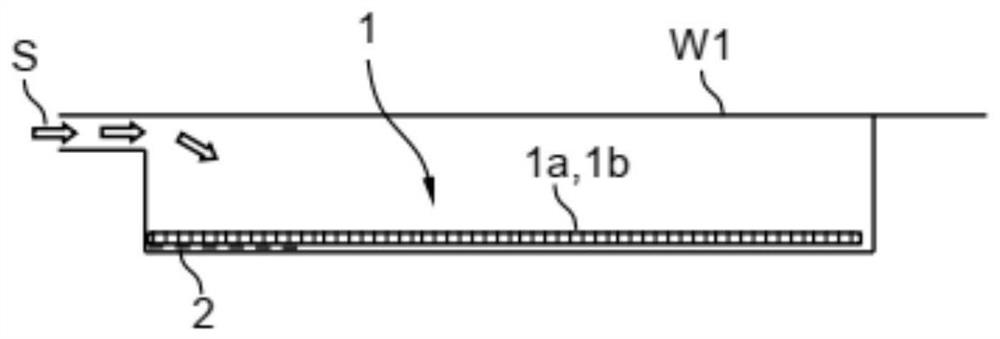

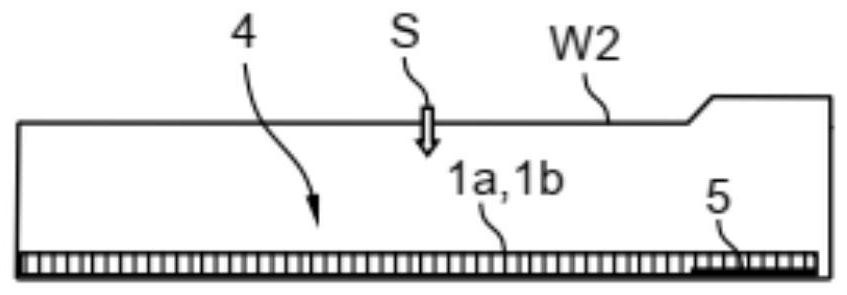

[0034] figure 1As a sectional illustration, a shaping tool W1 according to the invention is shown in side view, which in the present exemplary embodiment is designed as an injection molding tool W1. Inserted into the injection mold W1 is a base element 1 on which a contact strip 2 is mounted. The base element 1 is formed from a thin plastic film 1a on which, for example, a heating conductor circuit 1b has been embossed. Both ends of the heating conductor circuit 1 b are connected to corresponding lines of the contact strip 2 . The contact strip 2 is bendable and in particular so bendable that it can be turned over, as shown, under the lower flat side of the base element 1 to which the contact strip 2 is fastened. on the flat side. With the contact strip 2 turned upside down, the base element 1 is introduced into the injection mold W1 in such a way that the contact strip 2 is covered or covered and in particular lies entirely on the base Between the element 1 and the wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com