Winding device and winding method of module spiral winding pipe

A technology of spirally wound pipe and winding device, which is applied in the field of modular spirally wound pipe winding devices, can solve the problems of short service life of the machine, complicated forming process, time-consuming and labor-intensive, etc., and achieve reduced transportation costs, simple and practical structure, and simple forming process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

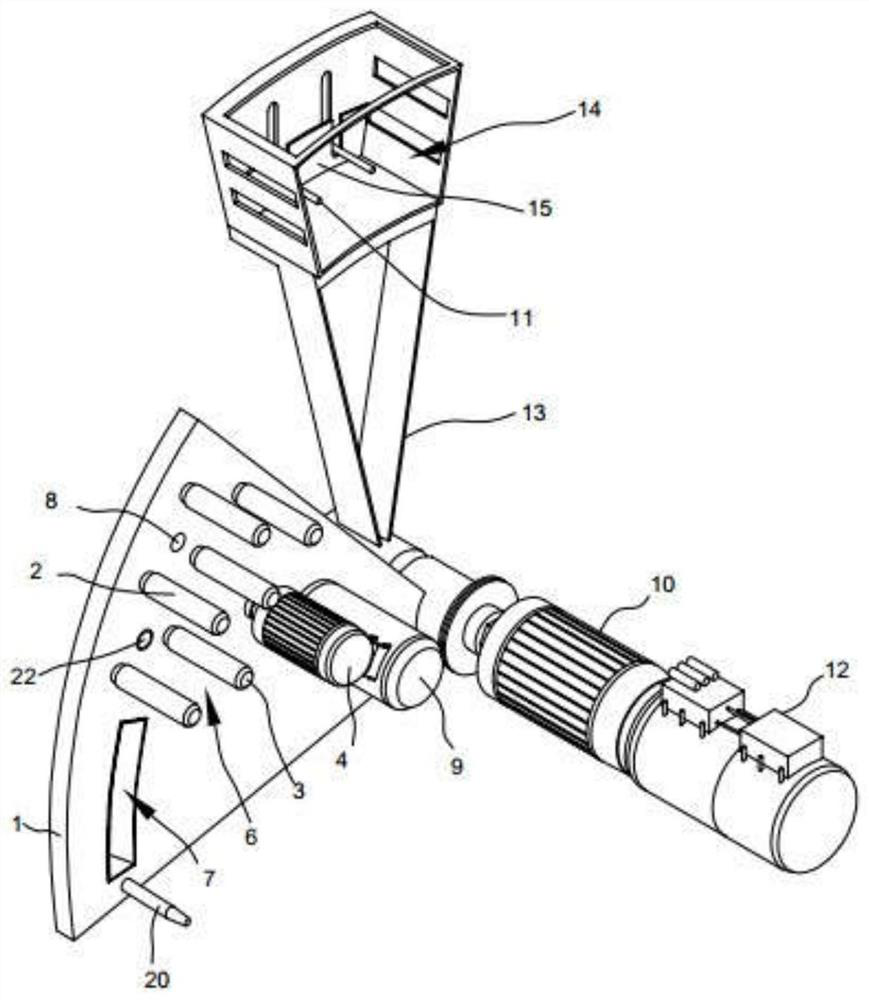

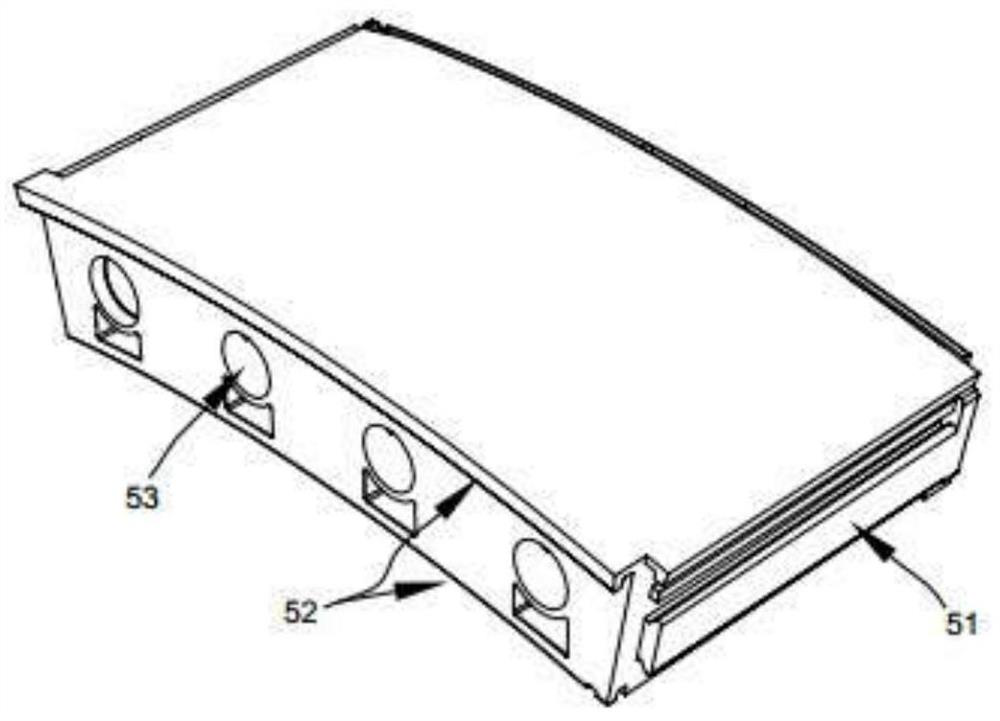

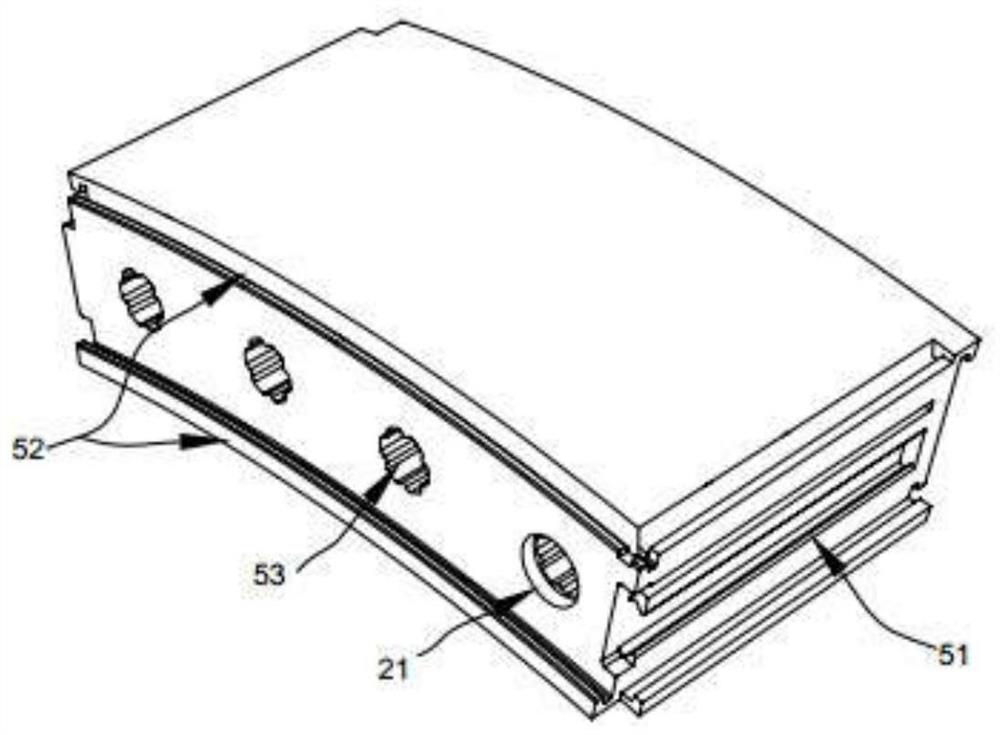

[0052] This embodiment differs from Embodiment 1 in that: Figure 8 As shown, due to the limitation of the diameter of the winding pipe, the excavated pipeline needs to arrange the feeding device 16 outside the pipeline. The feeding device 16 of this embodiment is arranged inside the helically wound pipe, and is suitable for the formation of non-excavated underground pipelines. Feeding device 16 is provided with traveling wheels that can walk along with the growth of the spirally wound pipe inside the pipeline, as Figure 8 As shown, the feeding device 16 is arranged at the bottom in the pipeline, and the original position of the feeding device swing arm 13 is also at the bottom directly opposite to the feeding device 16 conveying track. After the module 5 to be connected is loaded into the storage tank 14 on the swing arm 13 through the cylinder II11 on the swing arm 13, the swing arm 13 swings to the feed port 7 of the working panel 1 and the module 5 to be connected is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com