Method for directly recycling graphite anode material

A technology of graphite negative electrode and negative electrode material, which is applied in the direction of recycling technology, battery recycling, waste collector recycling, etc., to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

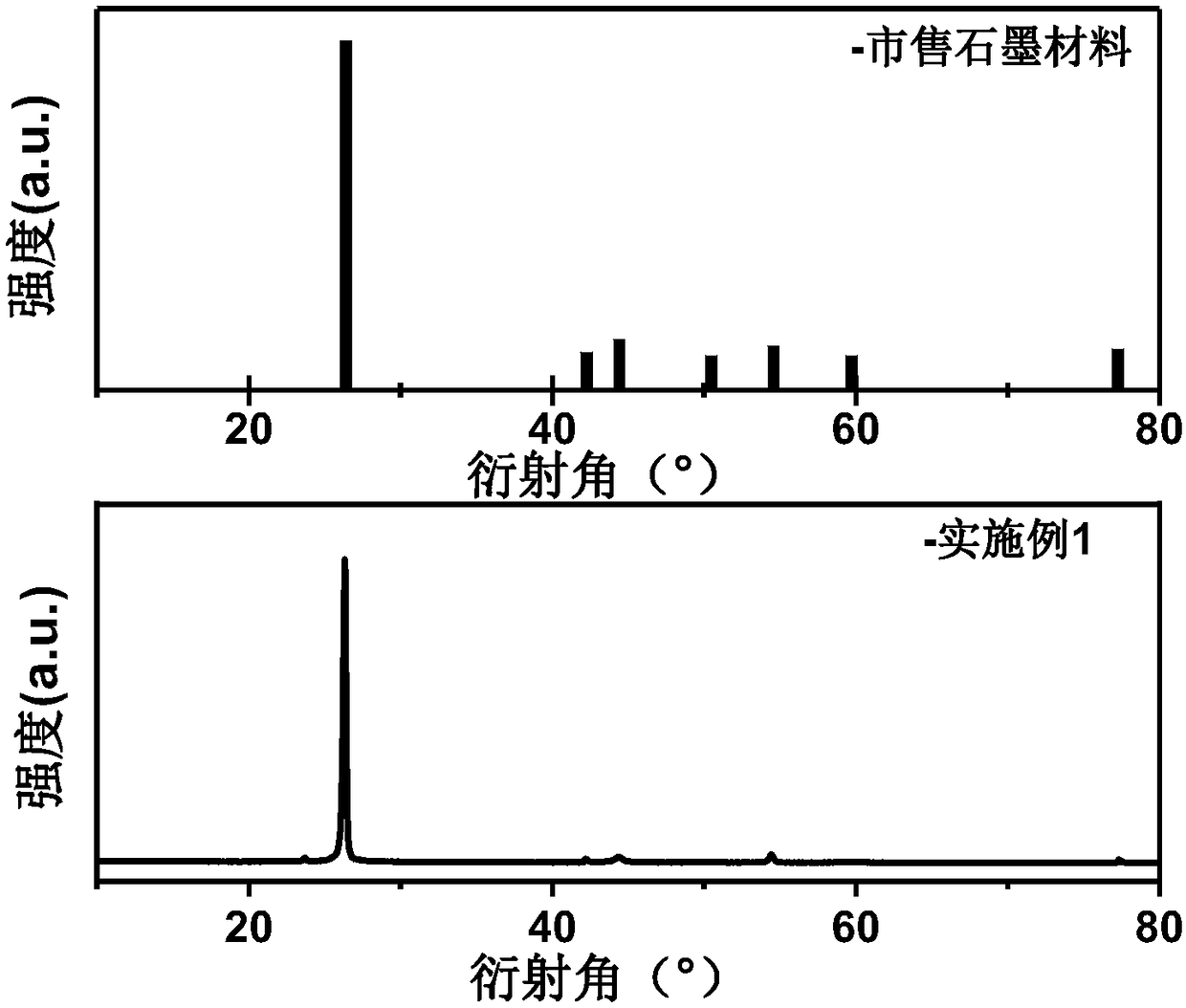

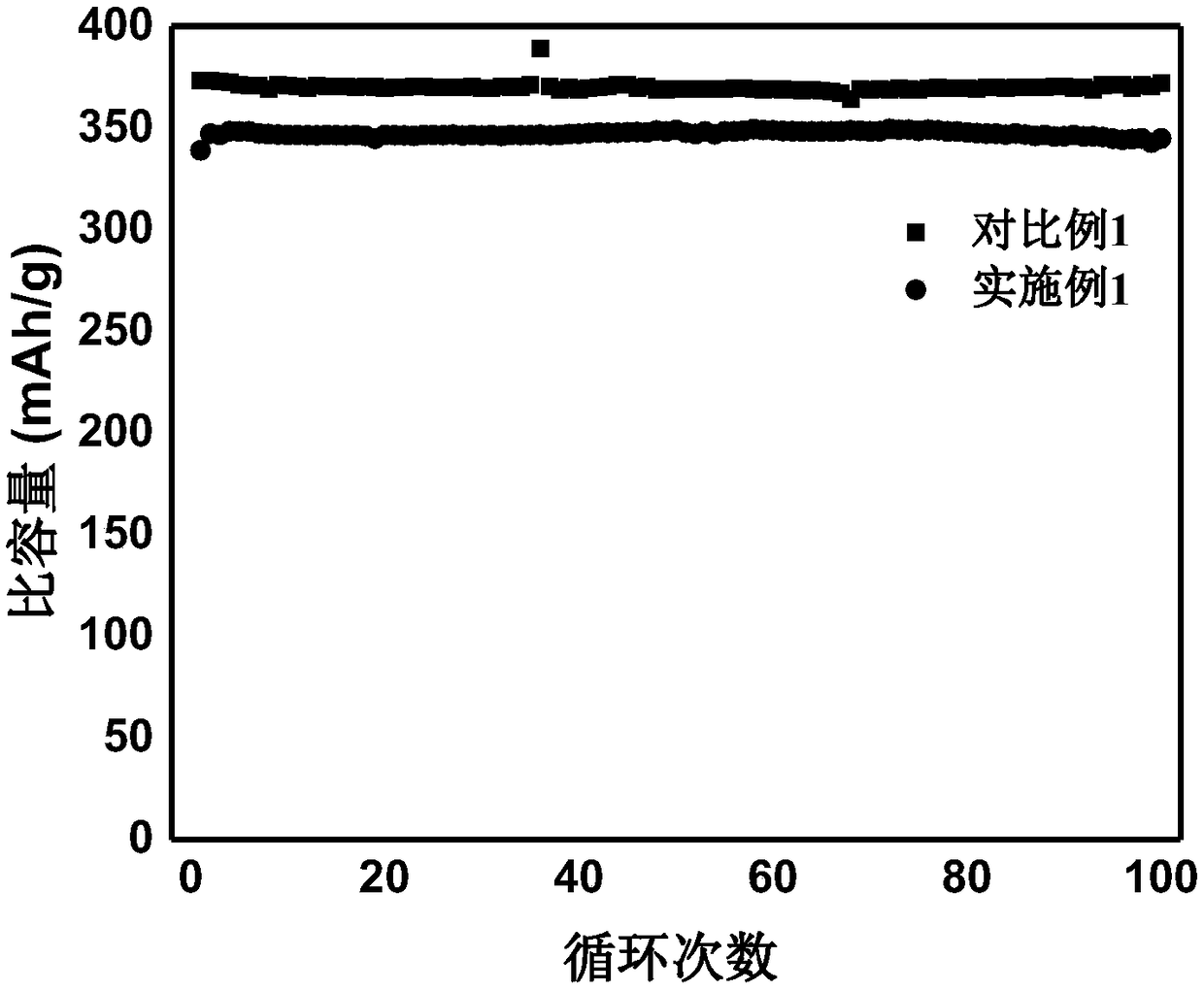

Embodiment 1

[0028] (1) Break the shell of the commercial waste power battery, peel off the graphite negative electrode sheet of the battery, and cut the electrode sheet into strips of 1*5cm.

[0029] (2) Put the treated negative electrode fragments in a clean large beaker, add deionized water at 25°C according to the ratio of the mass of the negative electrode piece to the mass of deionized water (1:20) for soaking for 1 min, and the negative electrode active material is immediately mixed with copper Foil separation, take out the copper foil from which the active material has been separated.

[0030] (3) Stir for 2 h at a stirring rate of 600 r / min under the action of a magnet, and after standing still for 12 h, pour the upper layer of turbid liquid, and add water again to make the volume of the solution equal to the original volume.

[0031] (4) Repeat step (3) 5 times, wash the sample with deionized water, then blow dry at 60°C, manually grind for 30 minutes, and then manually sieve thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com