Lithium metal electrode surface oxidized composite protective layer structure and preparation method thereof

A lithium metal electrode, surface oxidation technology, applied to battery electrodes, structural parts, non-aqueous electrolyte battery electrodes, etc., can solve the problems of poor processing performance of solid electrolyte materials, failure of composite protective layer, and easy breakage, and simplify battery assembly process, improving cycle stability, and suppressing the effect of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing a lithium metal electrode surface oxidation composite protective layer structure, comprising the steps of:

[0043] A. Fully dispersing the graphene oxide powder in an organic solvent to obtain a dispersion;

[0044] B. Add thioether containing benzene functional groups into the dispersion, mix and dissolve to obtain a coating solution;

[0045] C. Spray coating the coating solution on the battery separator base, and evaporate the solvent to obtain a separator with a uniform coating.

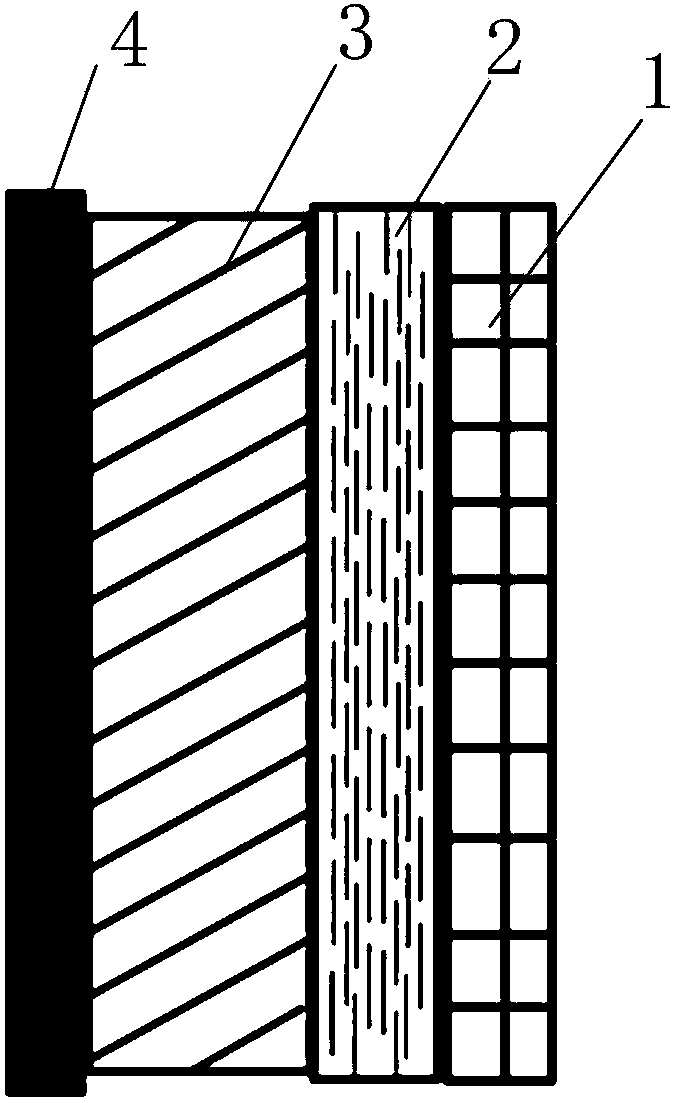

[0046] Such as figure 1 As shown, the oxidation composite protective layer structure includes an electronically insulating two-dimensional sheet structure layer, and the two-dimensional sheet structure layer is compounded with phenylene sulfide organic molecules as a lithium ion conducting medium.

[0047] The organic solvent is carbon disulfide, tetrahydrofuran or benzene;

[0048] Further, it also includes the step: D. Cover the separator on the lithium metal e...

Embodiment 1

[0052] Take the single-layer graphene oxide powder prepared by oxidation exfoliation, the average sheet thickness of graphene oxide is 1.1nm, and the sheet size D50 is about 22 μm, and 6.0g of the above-mentioned graphene oxide powder is ultrasonically dispersed in a benzene solvent to obtain a uniform dispersion solution. Add 4.0 g of diphenyl disulfide to the solution, and dissolve it after mechanical stirring to obtain a uniform mixed solution. Spray the above solution on the surface of the battery separator substrate and transfer it to an oven to evaporate the solvent to obtain a uniform coating. The thickness of the coating is 5 μm. The prepared separator 1 with a composite protective layer 2 is covered on the surface of the lithium metal electrode 3, and rolled together with the current collector 4 to obtain a lithium-graphene oxide composite protective layer integrated electrode.

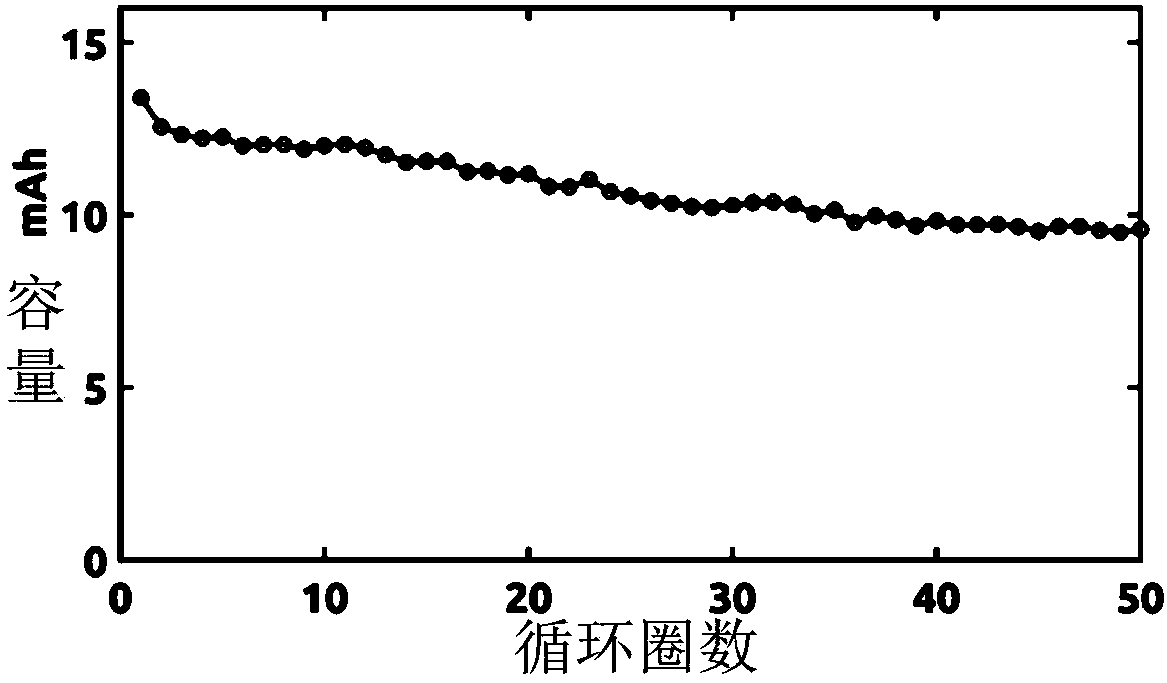

[0053] Using the above-mentioned lithium metal integrated electrode, a lithium-sulfur batt...

Embodiment 2

[0055] Take the single-layer graphene oxide powder prepared by oxidation exfoliation, the average sheet thickness of graphene oxide is 1.0nm, and the sheet size D50 is about 4.5 μm; ultrasonically disperse 2.0g of the above graphene oxide powder in a benzene solvent to obtain a uniform dispersion solution; Add 8.0 g of dinitrodiphenyl disulfide to the solution, and dissolve after mechanical stirring to obtain a uniform mixed solution; spray the above solution on the surface of the battery separator substrate and transfer it to an oven to evaporate the solvent to obtain a uniform coating. The thickness of the layer is 12 μm; the prepared separator with a composite protective layer is covered on the surface of the lithium metal electrode, and rolled together with the current collector to obtain a lithium-graphene oxide composite protective layer integrated electrode.

[0056] Using the above-mentioned lithium metal integrated electrode, a lithium-sulfur battery was assembled acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com