Outdoor non-reignition vacuum circuit breaker with high condensation resistance

A vacuum circuit breaker and dew condensation technology, which is applied to high-voltage air circuit breakers, circuits, high-voltage/high-current switches, etc., can solve problems such as insufficient effect, large system anti-shock backhaul, and opening failure, so as to reduce reciprocating vibration range, increase the speed of the whole process, and ensure the effect of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

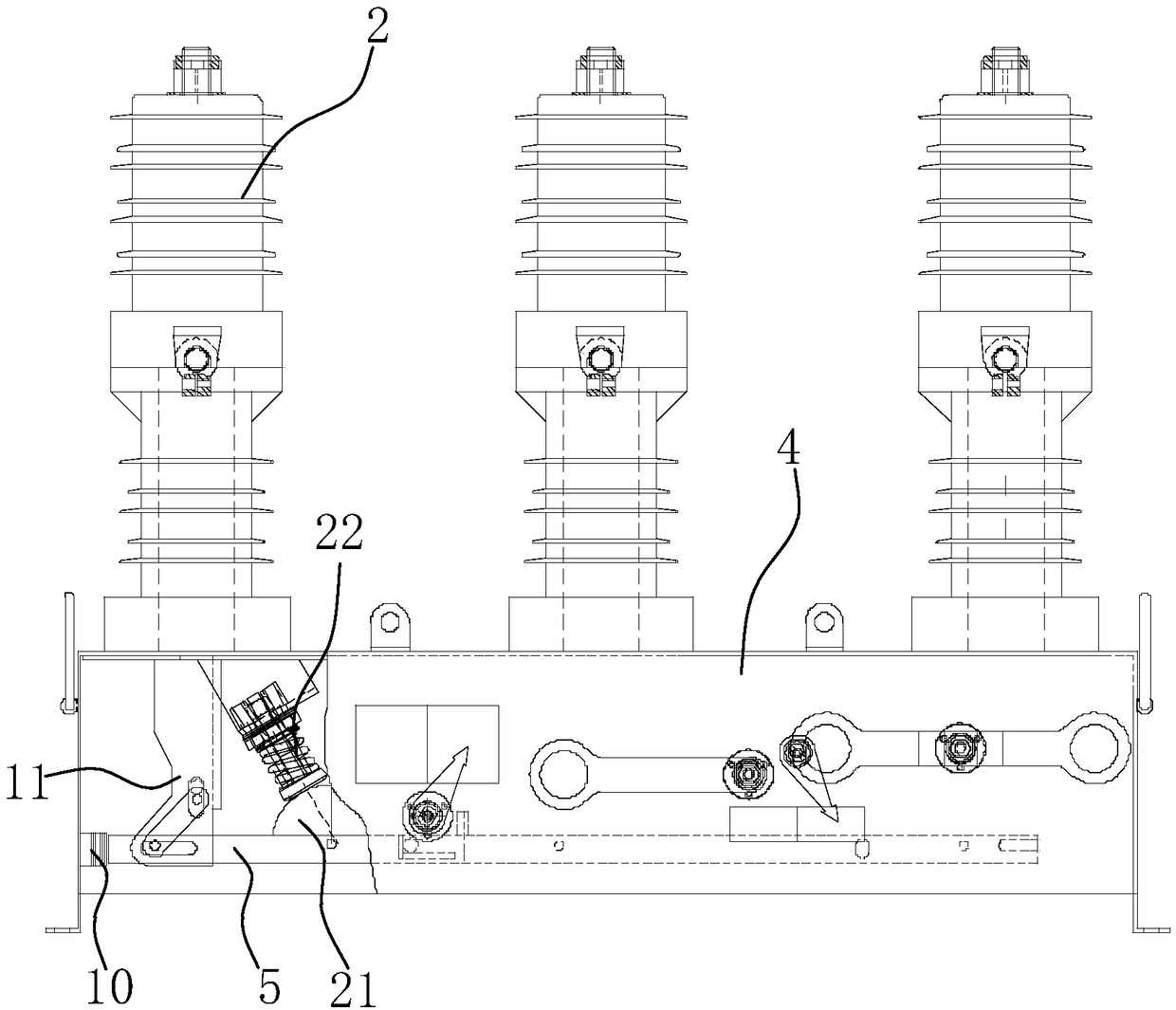

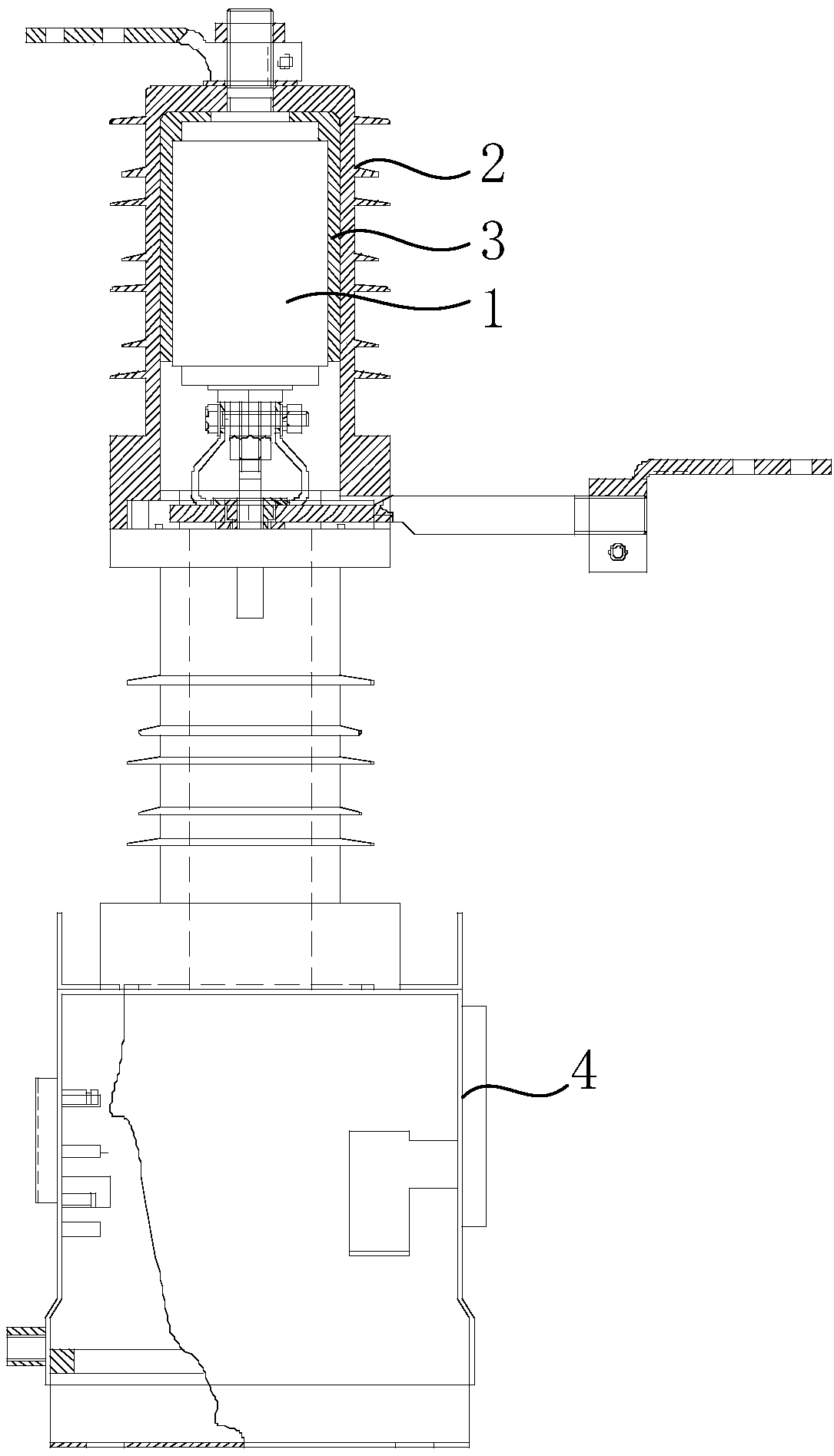

[0027] like Figure 2-6 As shown, the high anti-condensation outdoor non-reignition vacuum circuit breaker is mainly used for breaking and closing various load currents, overload currents and short-circuit currents in the power system of the distribution network, and is suitable for overhead lines and urban underground It is used for protection and control in cable lines, substations and power distribution systems of industrial and mining enterprises. It is more suitable for rural power grids and places with frequent operations. It is especially suitable for the needs of modern urban underground power pipe networks and intelligent upgrading of rural power grids. Use in alpine or humid areas.

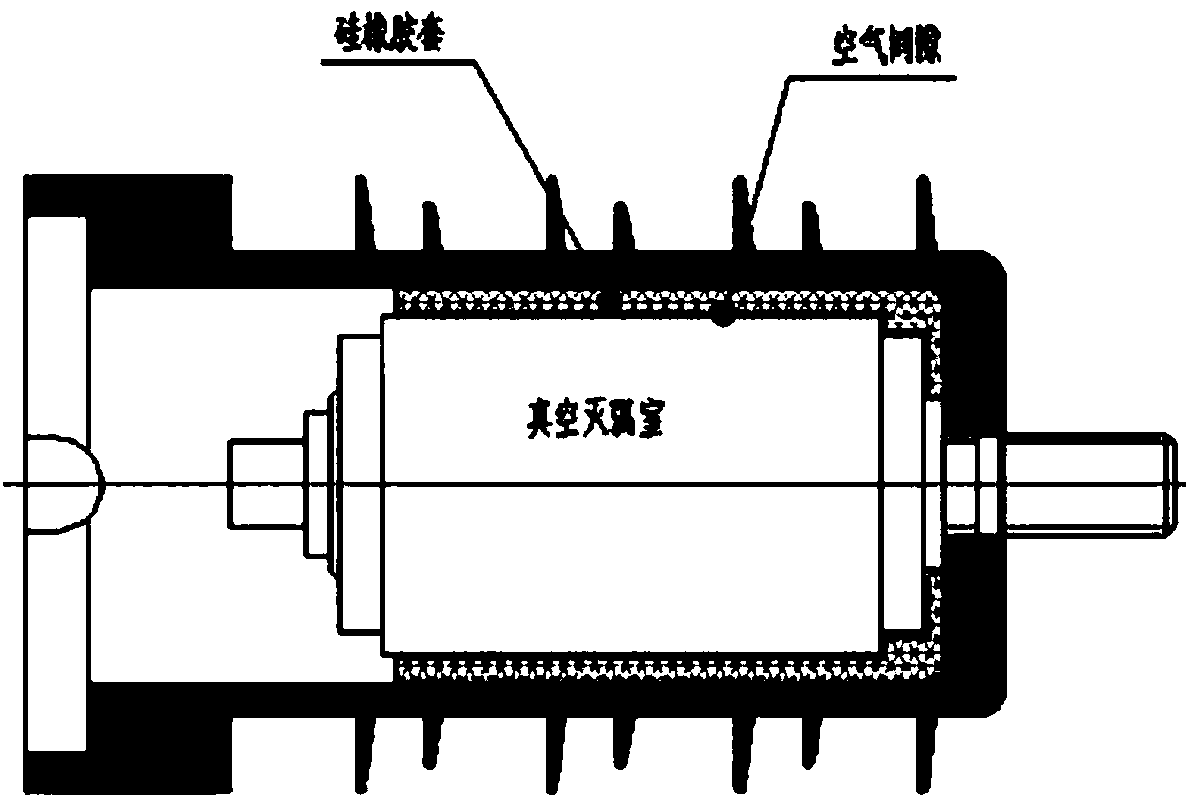

[0028] Its specific structure includes three vacuum interrupters 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com