Product defect detection method, apparatus and system, server and storage medium

A technology for product defects and detection methods, applied in the information field, can solve problems such as easy missed judgment and misjudgment, difficult business, and unfavorable production line optimization and upgrading, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

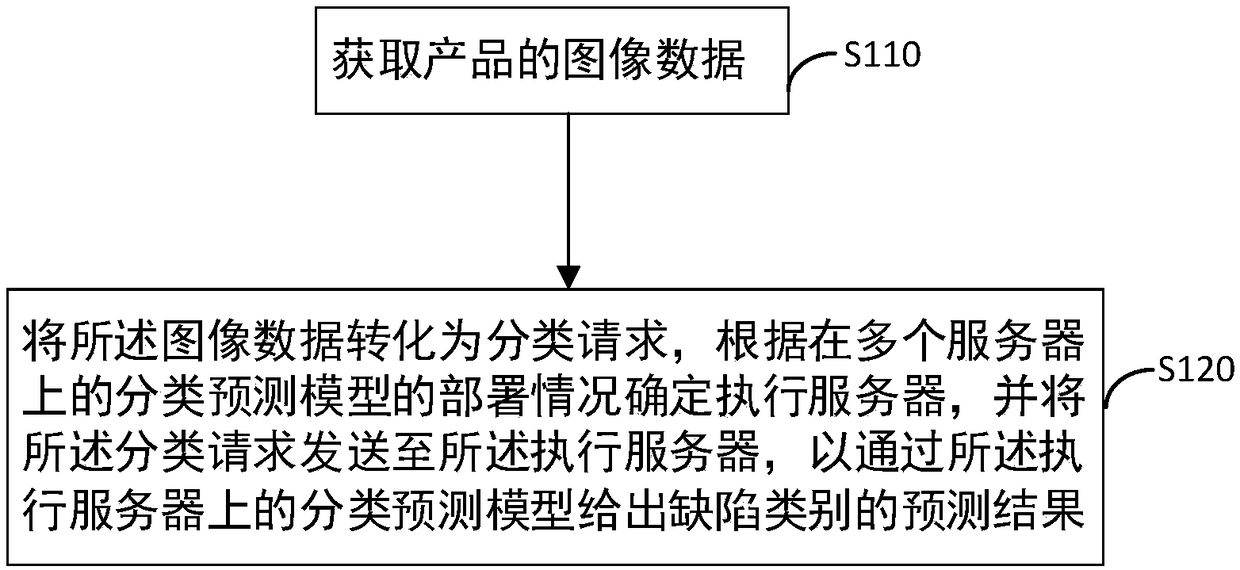

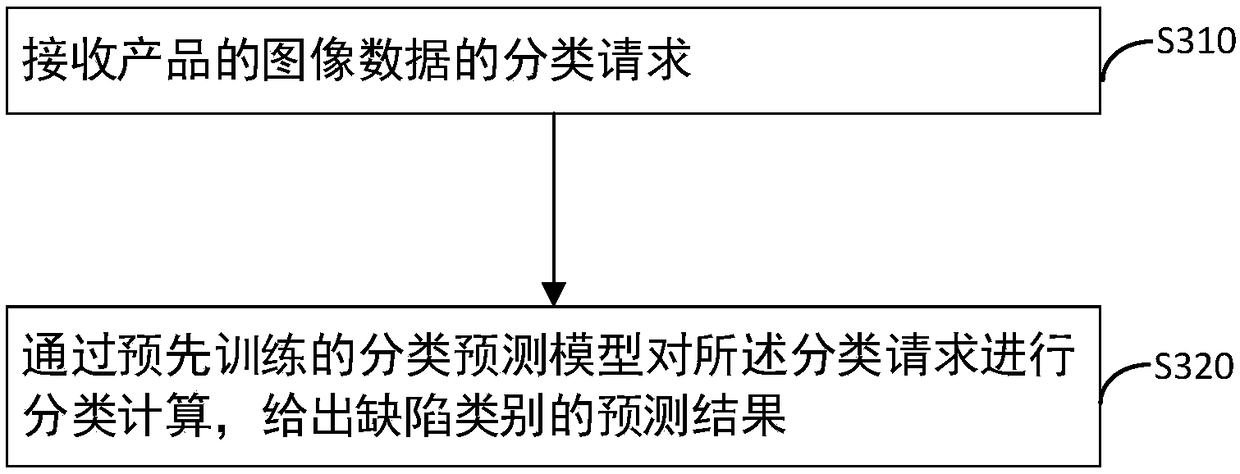

Method used

Image

Examples

Embodiment approach

[0044] According to an embodiment of the product defect detection method of the present invention, the method further includes: obtaining the classification prediction model through pre-training according to historical annotation data of product image data. Figure 4 It is a schematic workflow diagram of a preferred embodiment of the product defect detection method provided by the present invention. Such as Figure 4 As shown, the classification prediction model is trained by the training engine based on historical labeled data, which is stored in the training database, the training engine sends data requests to the training database, and the training database returns the training data to the training engine in response to the data requests. In addition, the production database stores data including the image data of recent products and the prediction results of defect categories corresponding to the image data of the products. The production database can provide data updates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com