Photoresist and micro-nano temperature and humidity sensitivity intelligent device and preparation methods thereof

A photoresist and device technology, applied in optomechanical equipment, photosensitive materials for optomechanical equipment, instruments, etc., to achieve the effect of increasing photothermal effect, wide light response band, and enhanced free radical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

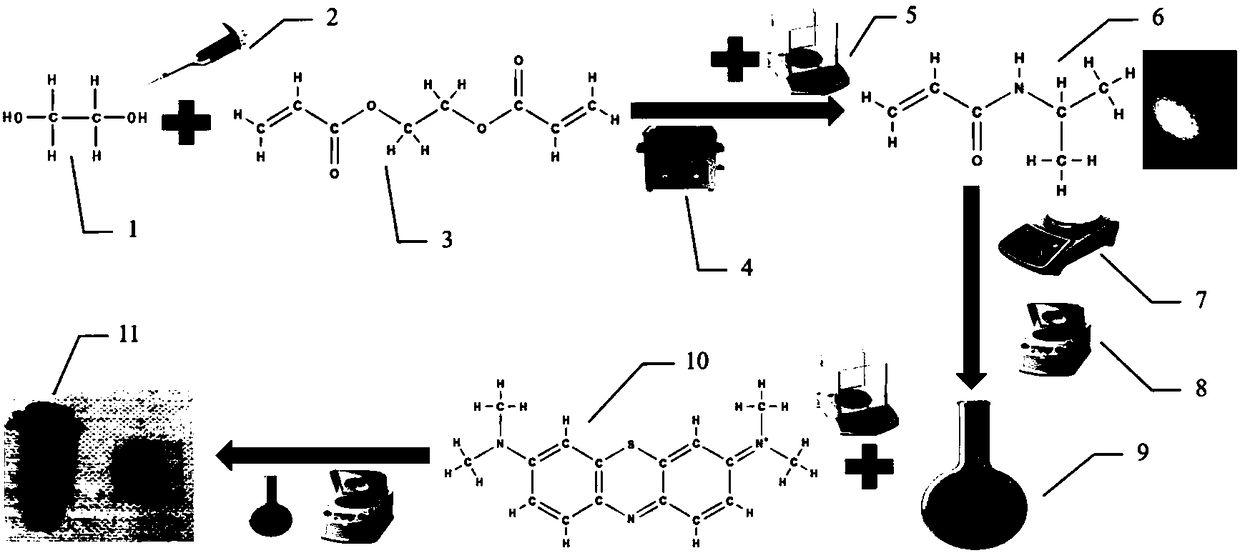

Embodiment 1

[0060] First, polynitrogen-isopropylacrylamide (2mol), methyl methacrylate (1mol), methylene blue (0.9 mg per ml of the mixture of thermosensitive monomer and hydrophilic acrylate) and ethanol (solute: solvent) The volume ratio is 10:0.9) as the photoresist component, and each component is prepared for use according to the amount of each component; then methyl methacrylate is dropped into ethanol, and ultrasonically shaken for 5 minutes; then polynitrogen-isopropyl is added Acrylamide, add a stirring vibrator and stir for 5 hours at a stirring speed of 900 rpm, remove the precipitate by centrifugation, and centrifuge at a speed of 3000 rpm; finally add methylene blue powder, ultrasonically vibrate for 10 minutes, stir for 4 hours, centrifuge again for purification, and centrifuge Speed 7000 rpm.

[0061] The density of the photoresist is similar to that of water, it has strong fluidity, is not viscous, and is light blue. The processing threshold region of low power processin...

Embodiment 2

[0063] First, poly-vinyl isobutyl amine (3 mol), polyethylene glycol diacrylate (1 mol), mercaptobenzothiazole (1.1 mg per ml of the mixture of thermosensitive monomer and hydrophilic acrylate) and Ethylene glycol (solute:solvent volume ratio is 5:1) is the photoresist component, and each component is prepared for use according to the amount of each component; then polyethylene glycol diacrylate is dropped into ethylene glycol, and ultrasonically oscillated 10 minutes; then add poly-vinyl isobutyl amide, magnetic stirring for 8 hours, stirring speed 1600 rpm; finally add mercaptobenzothiazole powder, ultrasonically vibrate for 15 minutes, stir for 8 hours, centrifuge again for purification, centrifugal speed 8000 rev / min to prepare a photoresist.

[0064] The photoresist has strong fluidity and transparent color on the glass substrate. Because the initiator activity is weaker than that of methylene blue, the low processing threshold region is 1-20mW, the high power threshold r...

Embodiment 3

[0066] First, polynitrogen-isopropylacrylamide (2.2mol), polyethylene glycol dimethacrylate (1mol), 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl) ) butanone (0.7 mg per milliliter of the mixture of temperature-sensitive monomer and hydrophilic acrylate) and ethanol (solute:solvent volume ratio of 10:1.5) are photoresist formulations, and each component is prepared according to the amount of each component. The ingredients are ready for use; then drop polyethylene glycol diacrylate in ethanol, and ultrasonically shake for 60 minutes; then add polyoxyethylene ether, stir magnetically for 5 hours, and stir at 1200 rpm; finally add 2-benzyl-2 -Dimethylamino-1-(4-morpholinophenyl)butanone powder, ultrasonically oscillated for about 60 minutes, stirred for 10 hours, and centrifuged again at 9000 rpm for purification to prepare a photoresist.

[0067] The low processing threshold region of the photoresist laser processing is 15-50 mW, the high power threshold region is 70-1200 mW, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com