Gear tooth profile error detecting device

An error detection and gear tooth profile technology, applied in the field of precision measurement, can solve the problems of high manufacturing cost, technical difficulty threshold, difficult promotion, complex system structure, etc., to achieve great convenience and operability, and avoid test installation errors , The effect of eliminating the secondary clamping error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

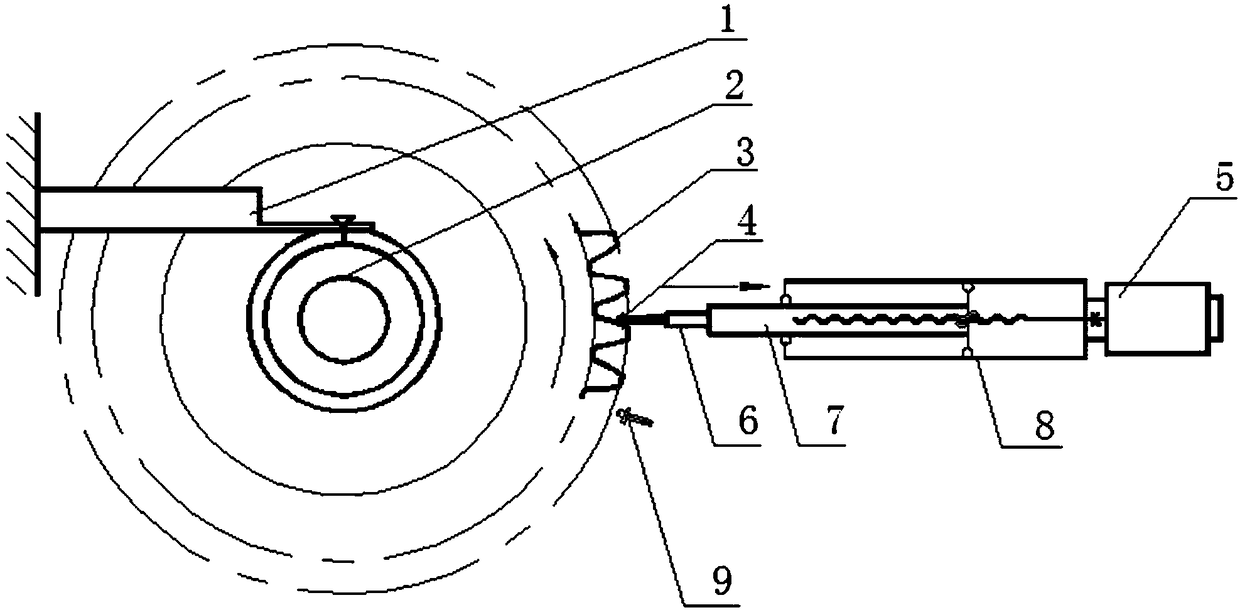

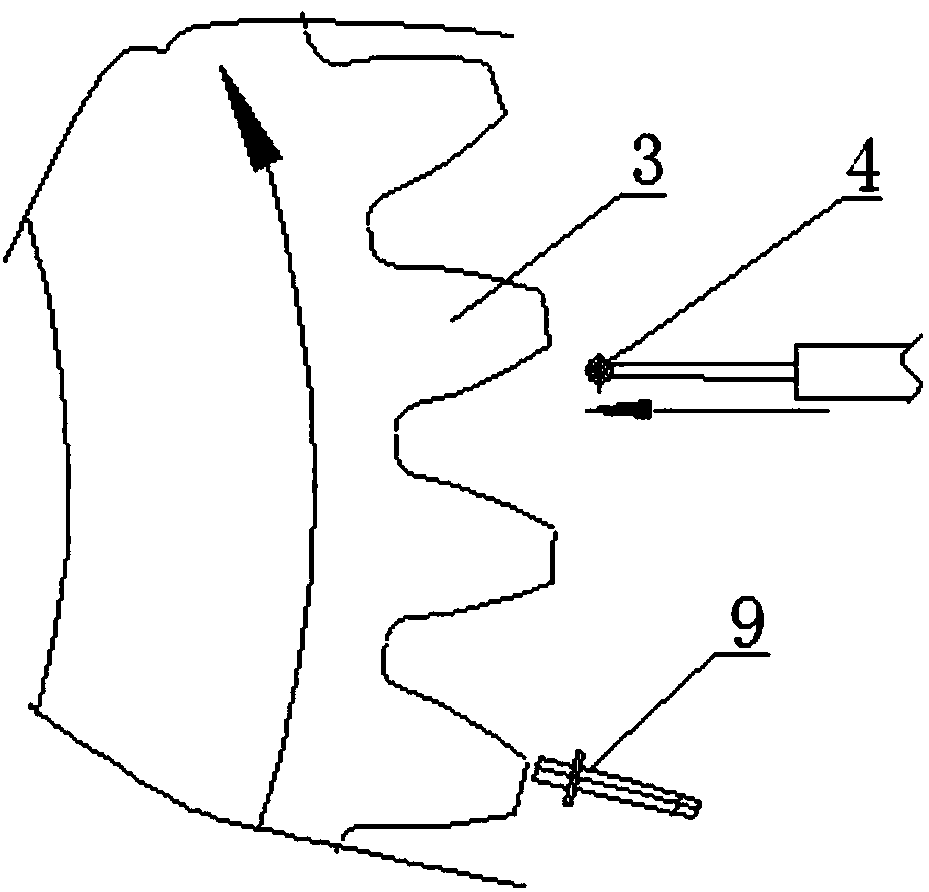

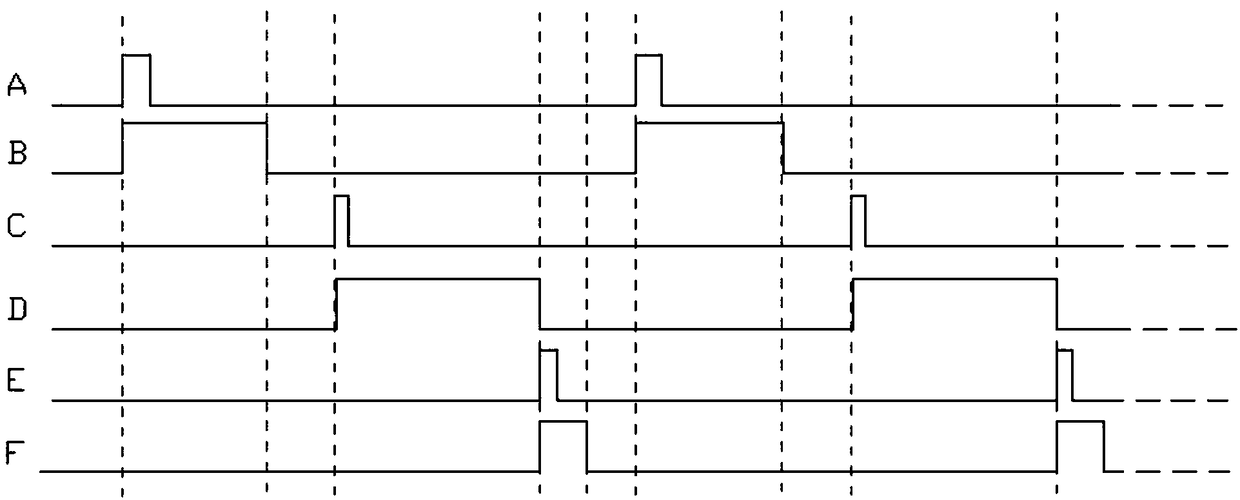

[0021] Such as figure 1 , 2 , shown in 4, a kind of gear tooth shape error detection device, comprises fixed support 1, angle encoder 2, measuring head 4, servo motor 5, micrometer sensor 6, telescoping rod 7 and industrial computer, described fixed support is used for The shell of the angle encoder is fixed so that when the encoder mandrel and the gear 3 rotate synchronously, the encoder shell remains stationary. The measuring head is connected with the micrometer sensor, the measuring head is arranged at the front end of the micrometer sensor, and the micrometer sensor is arranged at the front end of the telescopic rod, when the servo motor performs forward and rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com