A method for controlling furnace temperature

A control method and furnace temperature technology, applied in the direction of combustion method, incinerator, combustion type, etc., to achieve accurate flow regulation, reduce flow resistance, and improve measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

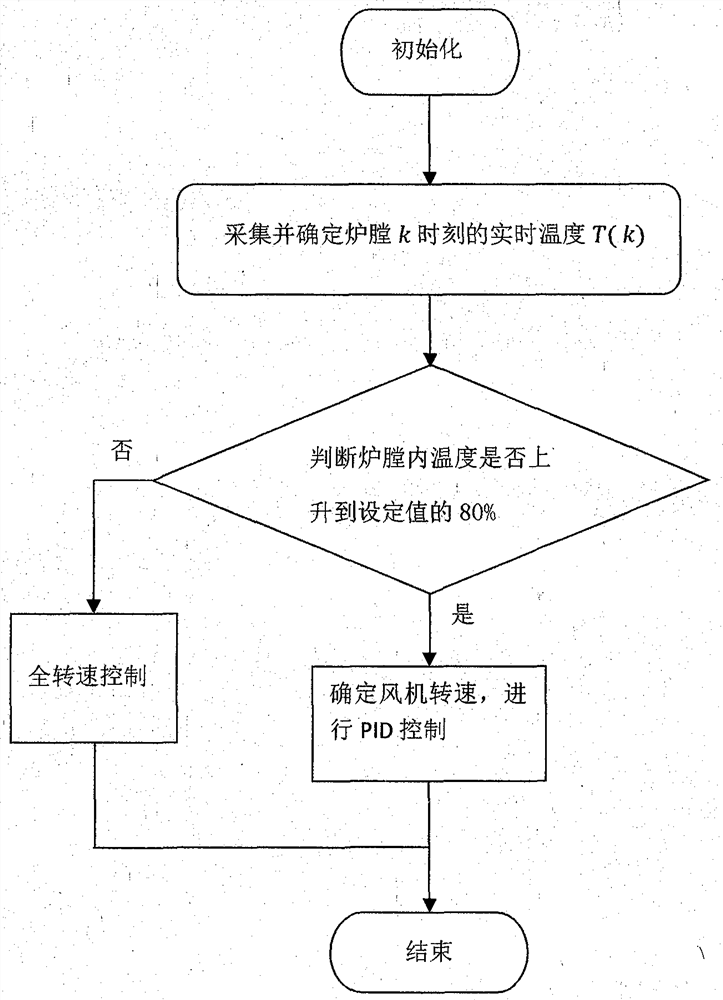

[0024] Such as figure 1 Shown, the concrete steps of the control method of a kind of furnace temperature of the present invention are as follows:

[0025] The first step: initialization, input pre-stored data. Input the pre-stored data to the controller through the input display device, that is, the corresponding relationship table between PID parameters and temperature difference, the target value of furnace temperature, and the maximum difference ΔT between two adjacent data collected by the same temperature sensor max , ΔT max = 1 degree.

[0026] Step 2: Determine whether the temperature in the furnace has risen to 80% of the set value, and determine the real-time temperature T(k) of the furnace at time k.

[0027]

[0028] In the formula: i=0~n, wherein, n is the number of temperature sensors in the furnace;

[0029] beta i is the weight coefficient of the i-th temperature sensor, and the weight coefficient is 0 to 1. The distance between the temperature sensor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com