Horizontal construction seam construction method of refuse incineration power plant structure pool project

A technology of engineering level and construction joints, which is applied in the direction of basic structure engineering, water conservancy engineering, underwater structures, etc., can solve the problems of easy dislocation, difficulty in fixing, deformation and displacement of waterstops, etc., to avoid leakage of the pool body, Ease of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

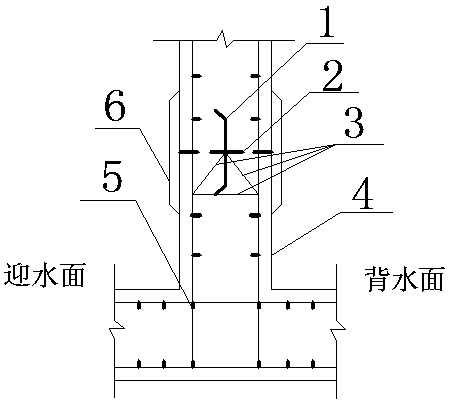

[0029] Specific embodiments: The steps of the horizontal construction joint construction method of the garbage power plant structure pool body project of the present invention are as follows:

[0030] Preparations include:

[0031] 1) if figure 1 According to the concrete strength grade and anti-seepage requirements of the pool body, select the appropriate steel bar specification and model for pouring the wall, and tie it into the wall steel bar skeleton 5;

[0032] 2) According to the concrete type of the pool body, select the appropriate formwork assembly, and install the lower formwork 4;

[0033] 3) The cleaning and treatment of the concrete at the bottom of the pool wall is convenient for pouring;

[0034] Steps:

[0035] 1) Install the steel plate waterstop: install the steel plate waterstop 1 at the horizontal position of the construction joint 2, the steel plate waterstop 1 is fixed with reinforced steel bars 3, including the lower part is borne by steel bar cross b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com