Graphene heating film

A kind of graphene heating film and graphite technology, applied in the field of graphene heating film, can solve the problems of heating film burns, uneven dispersion of fillers, fire, etc., and achieve the effects of easy cutting, light weight and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation process of dispersant is as follows:

[0045] step one,

[0046] Step two,

[0047] Wherein, the reaction temperature of step 1 is 110° C., and the reaction time is 5 hours; the reaction temperature of step 2 is 150° C., and the reaction time is 3.5 hours.

[0048] Regarding the film-forming resin, there are several options as follows. The film-forming resin includes oily resin; specifically, it can be selected as one or more of oily acrylic resin, oily epoxy resin, oily silicone resin, oily polyurethane resin and oily chlorine-containing resin. Several kinds; oily chlorine-containing resins include one or both of oily chlorine ether resins, oily perchlorethylene resins, and oily vinyl vinegar resins.

[0049] When choosing oleoresin, the curing agent includes

[0050] in, Here k is an integer in 1-6, which is prepared by the following steps:

[0051] That is the reaction of acid and polyenamine.

[0052] The film-forming resin includes wa...

Embodiment 1

[0056] A kind of graphene heating film, comprises film-forming component and curing agent, and the mass ratio of film-forming component and curing agent is 15:1; Curing agent is

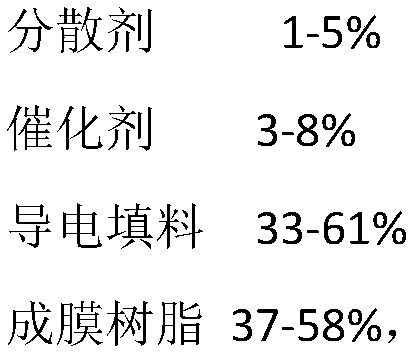

[0057] Wherein, film-forming component comprises each material of following mass percentage content:

[0058]

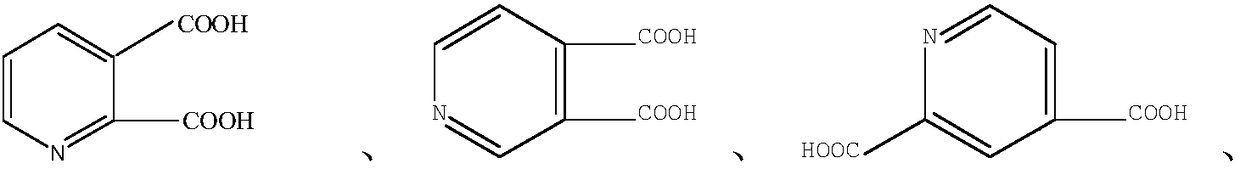

[0059] Wherein, the dispersant that the present application adopts comprises the material of following molecular structure:

[0060]

[0061] Catalysts include:

[0062]

[0063] During application, first, the film-forming components are stirred and mixed according to the proportion, and ground on a sand mill. When the grinding particle size reaches 1-5 microns, according to the mass ratio of film-forming components / curing agent=15 / 1, Add curing agent, stir evenly, coat on the substrate, dry at 150 degrees Celsius for half an hour, measure its resistance, the test value is 6Ω; when working, the working voltage is 24V, the heat production is 115W, and the infrared wavelength of r...

Embodiment 2

[0065] A kind of graphene heating film, comprises film-forming component and curing agent, and the mass ratio of film-forming component and curing agent is 15:1; Curing agent is

[0066] Wherein, film-forming component comprises each material of following mass percentage content:

[0067]

[0068] Wherein, the dispersant that the present application adopts comprises the material of following molecular structure:

[0069]

[0070] Catalysts include substances with the following molecular structures:

[0071]

[0072] For specific use, first stir and mix the various materials of the film-forming components, and grind them on a sand mill until the particle size is 1-5 microns; add a curing agent and stir evenly, and coat the substrate, at 150 ° C Baking for half an hour, measure the resistance; the resistance is 6Ω; when working, the working voltage is 24V, the heat production is 110W, and the infrared wavelength of radiation is 4-14 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com