High-barrier PE coating membrane for liquid food packaging and preparation method thereof

A liquid food, high-barrier technology, applied in coatings, polyamide coatings, etc., can solve the problems of high oxygen permeability and decreased barrier properties of modified PE films, reduce hydrophilicity and hygroscopicity, and improve adhesion Performance, the effect of reducing the oxygen transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

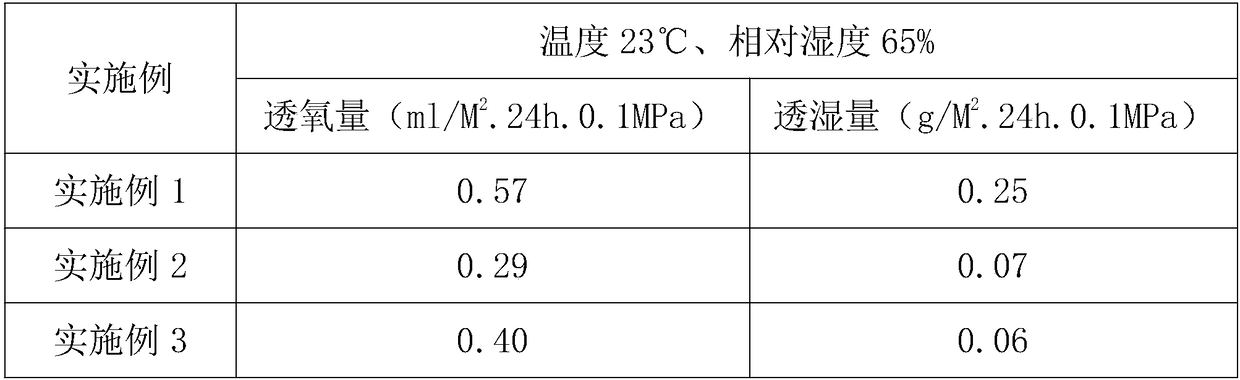

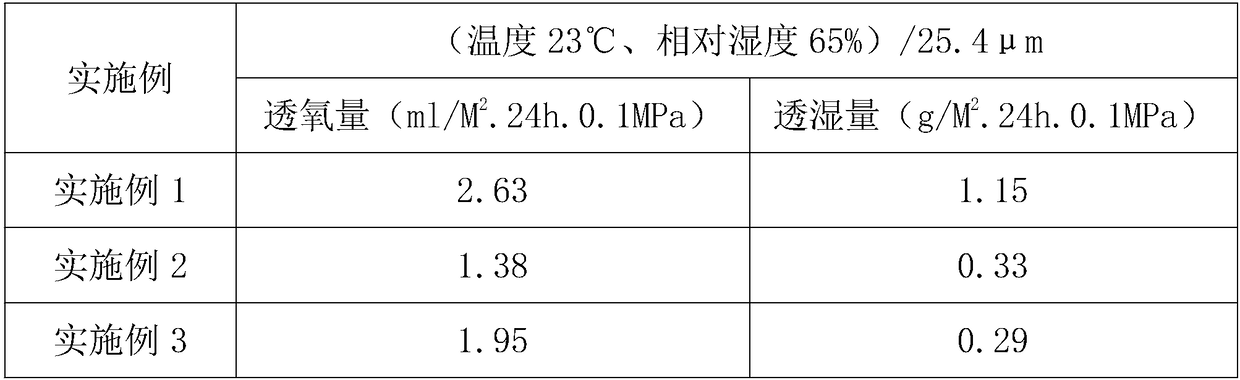

Examples

Embodiment 1

[0056] (1) Put 70 parts by mass of PE film into 20 parts by mass of acetone for extraction for 12 hours to remove various additives remaining on the surface during the preparation of the PE film. After the extraction, place the PE film in a vacuum-dried Dry in the oven at 55°C for 6 hours to remove acetone;

[0057] (2) Add 8 parts by mass of acetone to 120 parts by mass of absolute ethanol, stir and mix evenly, then add 40 parts by mass of ultrapure water, after dilution, continue to stir and mix uniformly to obtain acetone-water-ethanol Photoinitiator system solution;

[0058] (3) the methyl methacrylate of 10 mass parts is joined in the ultrapure water of 30 mass parts, stirs and mixes evenly, makes the methyl methacrylate photoinitiator system solution;

[0059] (4) Place the first layer of PE film processed through step (1) on the upper surface of the first piece of quartz glass, get 3ml of acetone-water-ethanol photoinitiator system solution with a dropper, drop evenly ...

Embodiment 2

[0079] (1) Put 75 parts by mass of PE film into 30 parts by mass of acetone for extraction for 15 hours to remove various additives remaining on the surface during the preparation of the PE film. After the extraction, place the PE film in a vacuum-dried Dry in the oven at 55°C for 7 hours to remove acetone;

[0080] (2) Add 10 parts by mass of acetone to 150 parts by mass of absolute ethanol, stir and mix evenly, then add 50 parts by mass of ultrapure water, after dilution, continue to stir and mix uniformly to obtain acetone-water-ethanol Photoinitiator system solution;

[0081] (3) the methyl methacrylate of 12 mass parts is joined in the ultrapure water of 35 mass parts, stirs and mixes evenly, makes the methyl methacrylate photoinitiator system solution;

[0082] (4) Place the first layer of PE film processed through step (1) on the upper surface of the first piece of quartz glass, get 4ml of acetone-water-ethanol photoinitiator system solution with a dropper, drop evenly...

Embodiment 3

[0102] (1) Put 80 parts by mass of PE film into 40 parts by mass of acetone for extraction for 18 hours to remove various additives remaining on the surface during the preparation of the PE film. After the extraction, place the PE film in a vacuum-dried Dry in the oven at 55°C for 8 hours to remove acetone;

[0103] (2) Add 12 parts by mass of acetone to 180 parts by mass of absolute ethanol, stir and mix evenly, then add 60 parts by mass of ultrapure water, after dilution, continue to stir and mix uniformly to obtain acetone-water-ethanol Photoinitiator system solution;

[0104] (3) the methyl methacrylate of 15 mass parts is joined in the ultrapure water of 40 mass parts, stirs and mixes evenly, makes the methyl methacrylate photoinitiator system solution;

[0105] (4) Place the first layer of PE film processed through step (1) on the upper surface of the first piece of quartz glass, get 5ml of acetone-water-ethanol photoinitiator system solution with a dropper, drop evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com