Palladium ion imprinted polymer and preparation method and application thereof

A technology of imprinting polymer and palladium ions, which is applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problem of less research on the preparation of palladium ion-imprinted polymers, lack of isothermal adsorption properties, and heavy metal selective adsorption research, etc. problem, to achieve the effect of low production cost, good environmental performance and simple regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

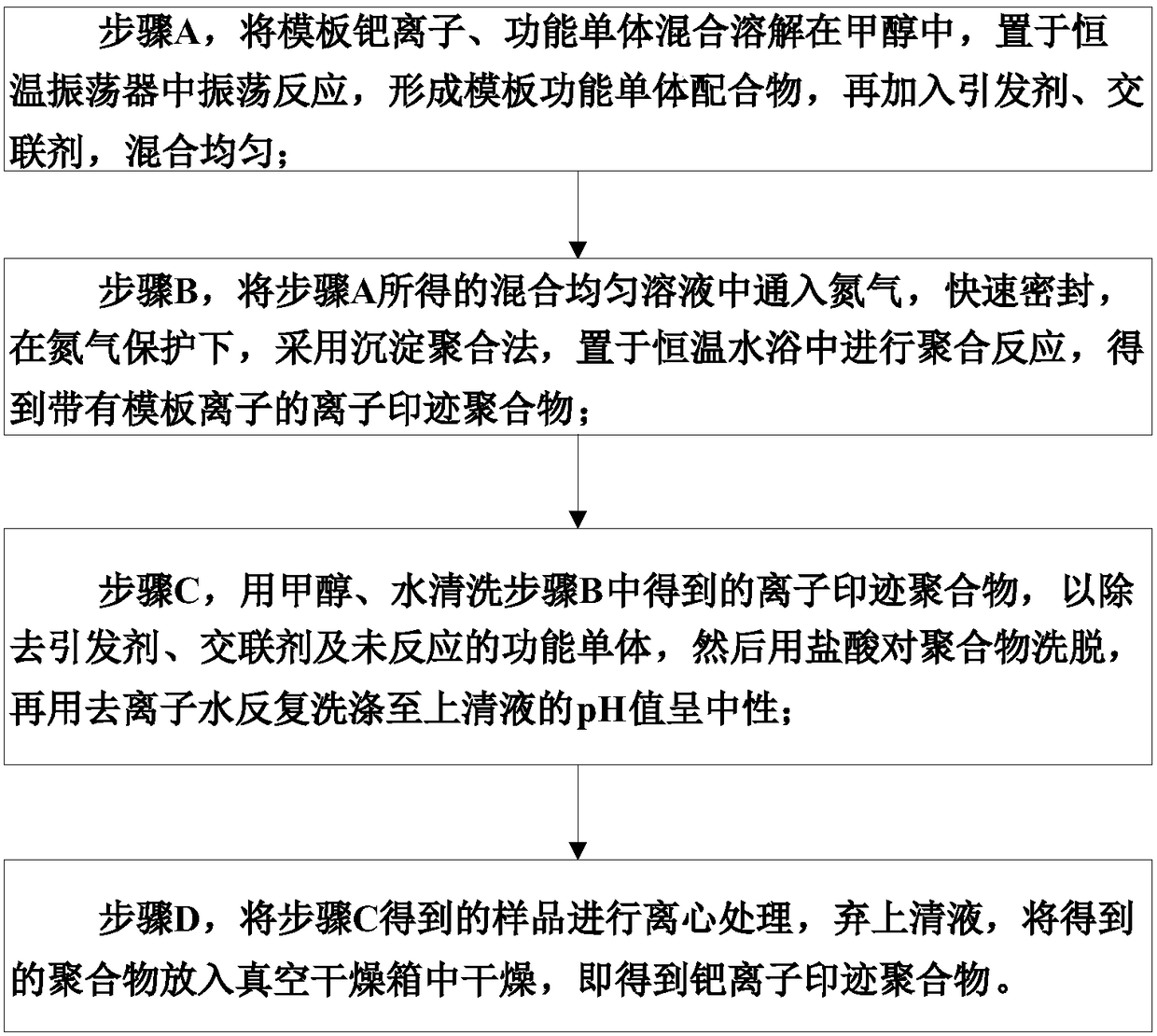

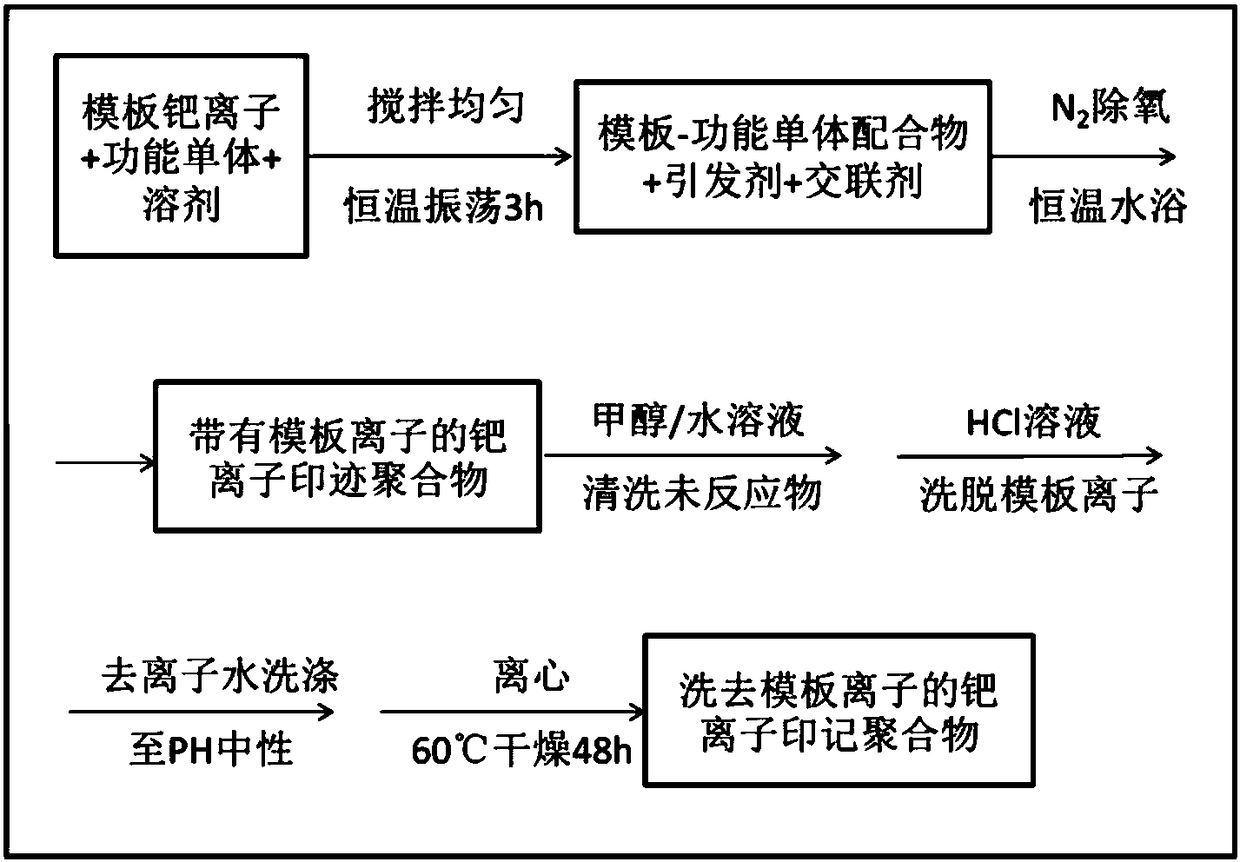

[0031] Specifically, for a preparation method of a palladium ion-imprinted polymer of the present invention, please refer to Figure 1-Figure 2 , including the following steps:

[0032] Step A, the template palladium ion PdCl 4 2- 1. Functional monomers are mixed and dissolved in methanol, placed in a constant temperature oscillator to oscillate and react to form a template functional monomer complex, and then add an initiator and a crosslinking agent and mix evenly; wherein, the functional monomer is 4-ethylene ylpyridine, 2-allylthionicotinic acid or 2-acetamidoacrylic acid, the initiator is azobisisobutyronitrile, and the crosslinking agent is ethylene glycol dimethacrylate.

[0033] In step B, inject nitrogen into the homogeneously mixed solution obtained in step A, quickly seal it, and under the protection of nitrogen, adopt the precipitation polymerization method and place it in a constant temperature water bath for polymerization to obtain an ion-imprinted polymer wit...

Embodiment 1

[0043] Weigh 32.64mg K 2 PdCl 4 , placed in a centrifuge tube filled with 20mL of methanol, 42.06mg of 4-vinylpyridine was added to it, and placed in a constant temperature oscillator (180rpm, 25°C) for oscillating reaction for 3h, and the palladium ion PdCl 4 2- After fully reacting with the functional monomer, add 75.3mL crosslinking agent ethylene glycol dimethacrylate EGDMA and 36.13mg initiator azobisisobutyronitrile AIBN (the amount is the molar weight of functional monomer and crosslinking agent 5% of the sum). After fully mixing, transfer it into a thick-walled pressure-resistant bottle, pass nitrogen gas for 10 minutes, seal the bottle quickly under the protection of nitrogen gas, and then shake and react in a constant temperature water bath at 60°C at a shaking rate of 180rpm for 24 hours. Dry, water should be added at regular intervals. After thermal polymerization, the polymer synthesized in the thick-walled pressure-resistant bottle was transferred to a large-...

Embodiment 2

[0046] Weigh 32.64mg K 2 PdCl 4 , placed in a centrifuge tube filled with 20mL of methanol, 78.10mg of 2-allylthionicotinic acid ANA was added to it, and placed in a constant temperature oscillator (180rpm, 25°C) for oscillating reaction for 3h, and the palladium ion PdCl 4 2- After fully reacting with the functional monomer, add 75.3mL crosslinking agent ethylene glycol dimethacrylate EGDMA and 36.13mg initiator azobisisobutyronitrile AIBN (the amount is the molar weight of functional monomer and crosslinking agent 5% of the sum). After fully mixing, transfer it into a thick-walled pressure-resistant bottle, pass nitrogen gas for 10 minutes, seal the bottle quickly under the protection of nitrogen gas, and then shake and react in a constant temperature water bath at 60°C at a shaking rate of 180rpm for 24 hours. Dry, water should be added at regular intervals. After thermal polymerization, the polymer synthesized in the thick-walled pressure-resistant bottle was transferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com