Energy-saving, emission-reducing and high-efficiency corn starch processing method

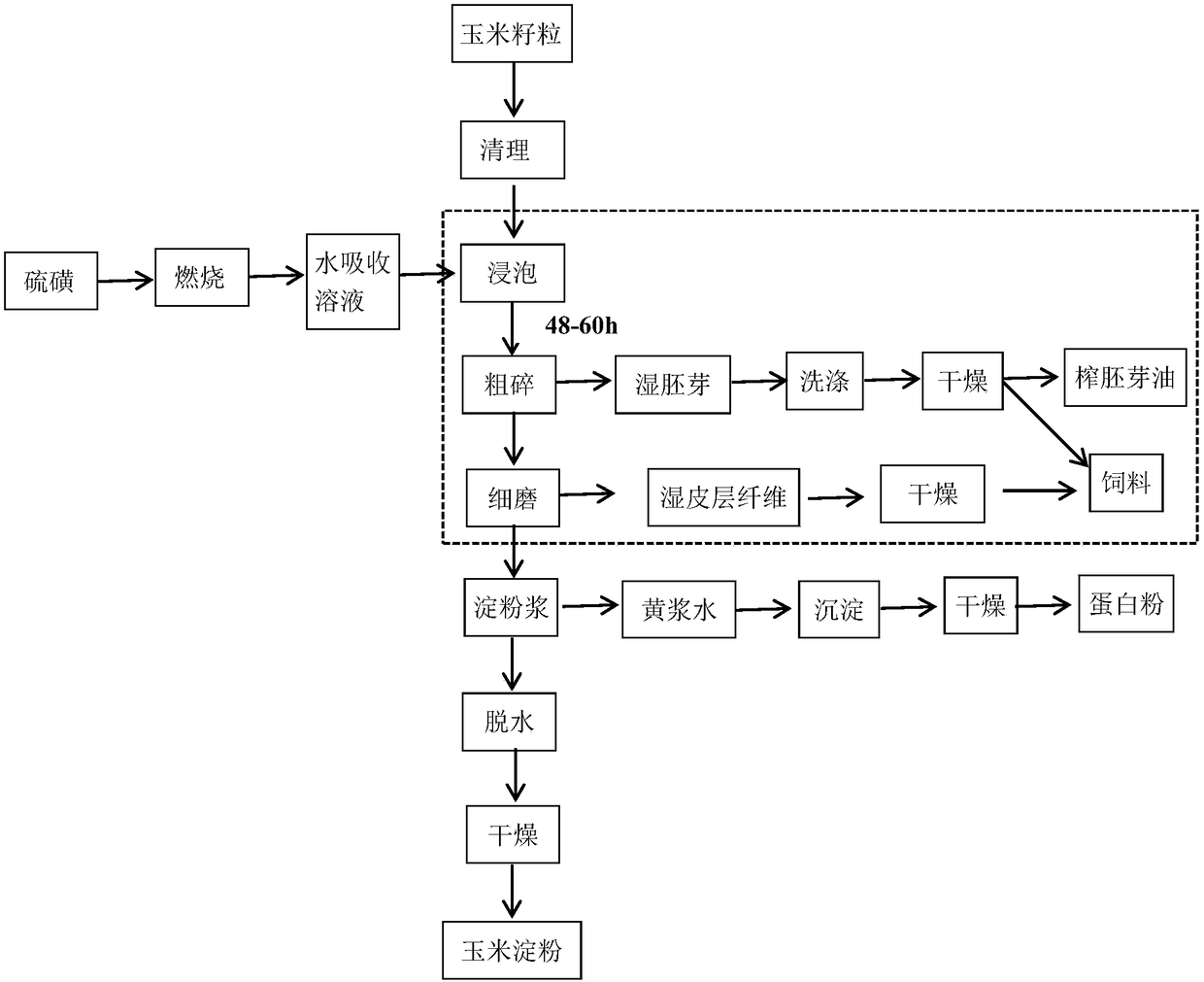

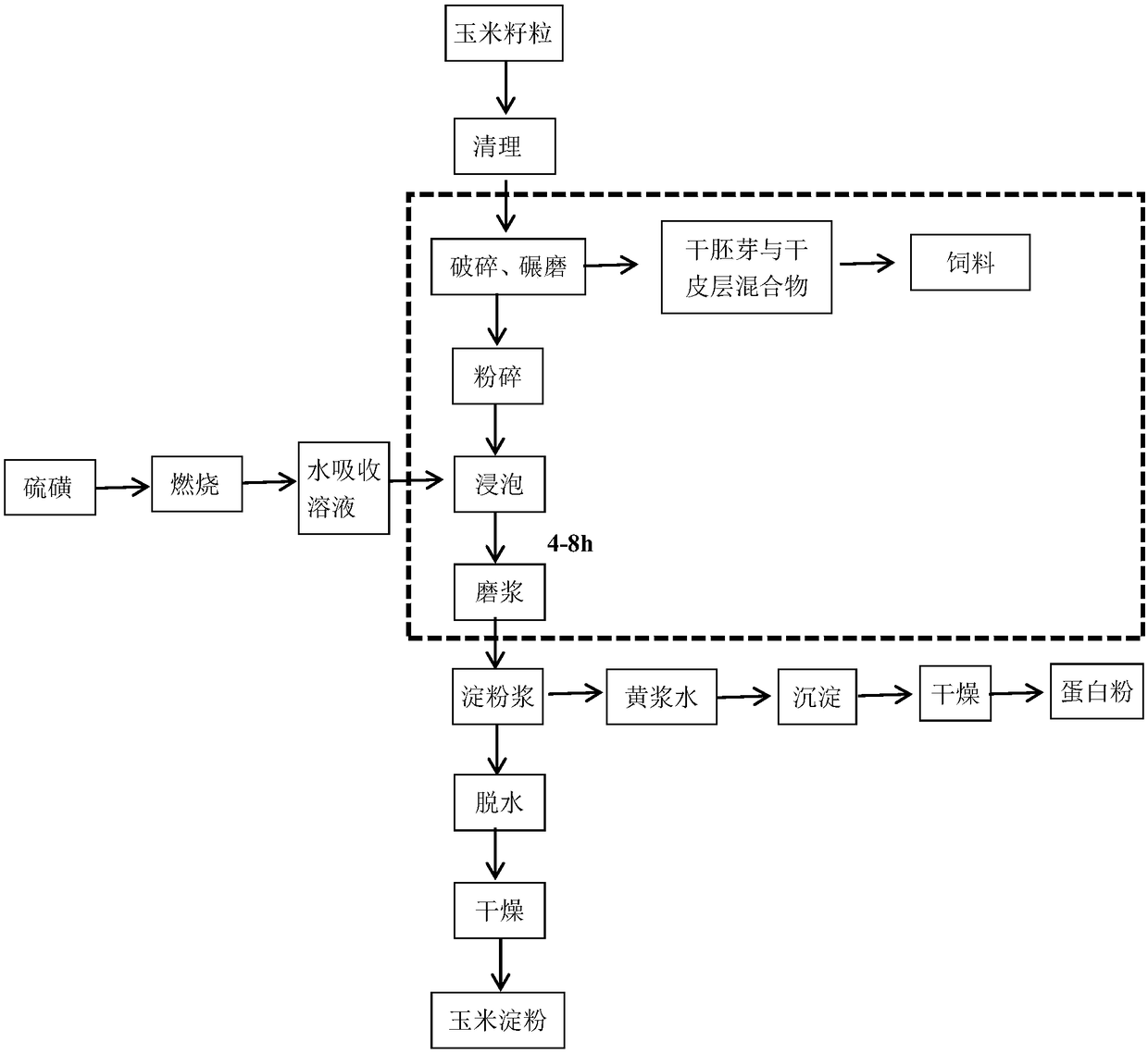

The technology of a corn starch and a processing method, which is applied in the field of food processing, can solve the problems of high energy consumption, low production efficiency of corn starch, and large sewage, and achieve the effects of reducing waste water discharge, saving soaking time, and saving water resources and electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The processing method of embodiment 1. cornstarch.

[0029] 1) Crushing and grinding of corn kernels: take 10kg of corn kernels, clean up the impurities, use corn dregs processing equipment to crush and grind corn kernels, remove the germ and cortex, and collect the mixture of germ and cortex for feed processing .

[0030] 2) Grinding: Grinding the corn kernels with germ and cortex removed into 20-mesh fine powder.

[0031] 3) Soaking: Preparation of sulfurous acid: burn sulfur to generate sulfur dioxide, then absorb sulfur dioxide with water to generate sulfurous acid solution; soak corn flour with 30L sulfurous acid solution with a mass fraction of 0.2%, soak at 48°C for 8 hours.

[0032] 4) Fine grinding: refining the sulfurous acid soaking solution containing corn flour in step 3), the mesh size is 100 mesh, and separating the starch to obtain starch slurry.

[0033] 5) Centrifugal dehydration: The starch slurry is subjected to centrifugal dehydration at a rotatio...

Embodiment 2

[0035] The processing method of embodiment 2. cornstarch.

[0036] 1) Crushing and grinding of corn kernels: take 10kg of corn kernels, clean up the impurities, use corn dregs processing equipment to crush and grind corn kernels, remove the germ and cortex, and collect the mixture of germ and cortex for feed processing .

[0037] 2) Grinding: Grinding the corn kernels with germ and cortex removed into 20-mesh fine powder.

[0038] 3) Soaking: Preparation of sulfurous acid: burn sulfur to generate sulfur dioxide, then absorb sulfur dioxide with water to generate sulfurous acid solution; soak corn flour with 30L sulfurous acid solution with a mass fraction of 0.25%, soak at 50°C for 6h.

[0039] 4) Fine grinding: refining the sulfurous acid soaking solution containing corn flour to a mesh size of 110 mesh, separating the starch to obtain starch slurry.

[0040] 5) Centrifugal dehydration: The starch slurry is subjected to centrifugal dehydration at a speed of 7500r / min for 15 ...

Embodiment 3

[0042] The processing method of embodiment 3. cornstarch.

[0043] 1) Crushing and grinding of corn kernels: take 10kg of corn kernels, clean up the impurities, use corn dregs processing equipment to crush and grind corn kernels, remove the germ and cortex, and collect the mixture of germ and cortex for feed processing .

[0044] 2) Grinding: Grinding the corn kernels with germ and cortex removed into 20-mesh fine powder.

[0045] 3) Soaking: Preparation of sulfurous acid: burn sulfur to generate sulfur dioxide, then absorb sulfur dioxide with water to generate sulfurous acid solution; soak corn flour with 30L sulfurous acid solution with a mass fraction of 0.3%, soak at 52°C for 4h.

[0046] 4) Fine grinding: refining the sulfurous acid soaking solution containing corn flour to a mesh size of 120, separating the starch to obtain starch slurry.

[0047] 5) Centrifugal dehydration: the starch slurry is subjected to centrifugal dehydration at a speed of 10000 r / min for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com