Method for preparing porous carbon material from allyl wastes and application

A waste and porous carbon technology, which is applied in the field of biochar material preparation, can solve the problems of environmental pollution, strong irritating odor of garlic residue, waste of resources, etc., and achieve good wettability, improved electrochemical performance, and low time constant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In yet another embodiment of the present invention, a method for preparing a garlic-based waste porous carbon material for supercapacitors is provided, the method comprising:

[0048] S1. Heat and carbonize the garlic-based waste in an inert atmosphere, the carbonization temperature is 400-800°C, and the carbonization time is 80min-150min;

[0049] S2. Pickling the product obtained in step S1, and then washing it with water until neutral;

[0050] S3. Immersing the product obtained in step S2 in a chemical activator;

[0051] S4. The product obtained in step S3 is heated and activated at a heating temperature of 700-900° C. for 60-140 minutes; after pickling, water washing and drying, a garlic-based waste porous carbon material is obtained.

[0052] In yet another specific embodiment of the present invention, in the step S1,

[0053] Before the garlic-based waste is heated and carbonized, it is washed, dried, crushed and sieved;

[0054] Further, the drying treatment...

Embodiment 1

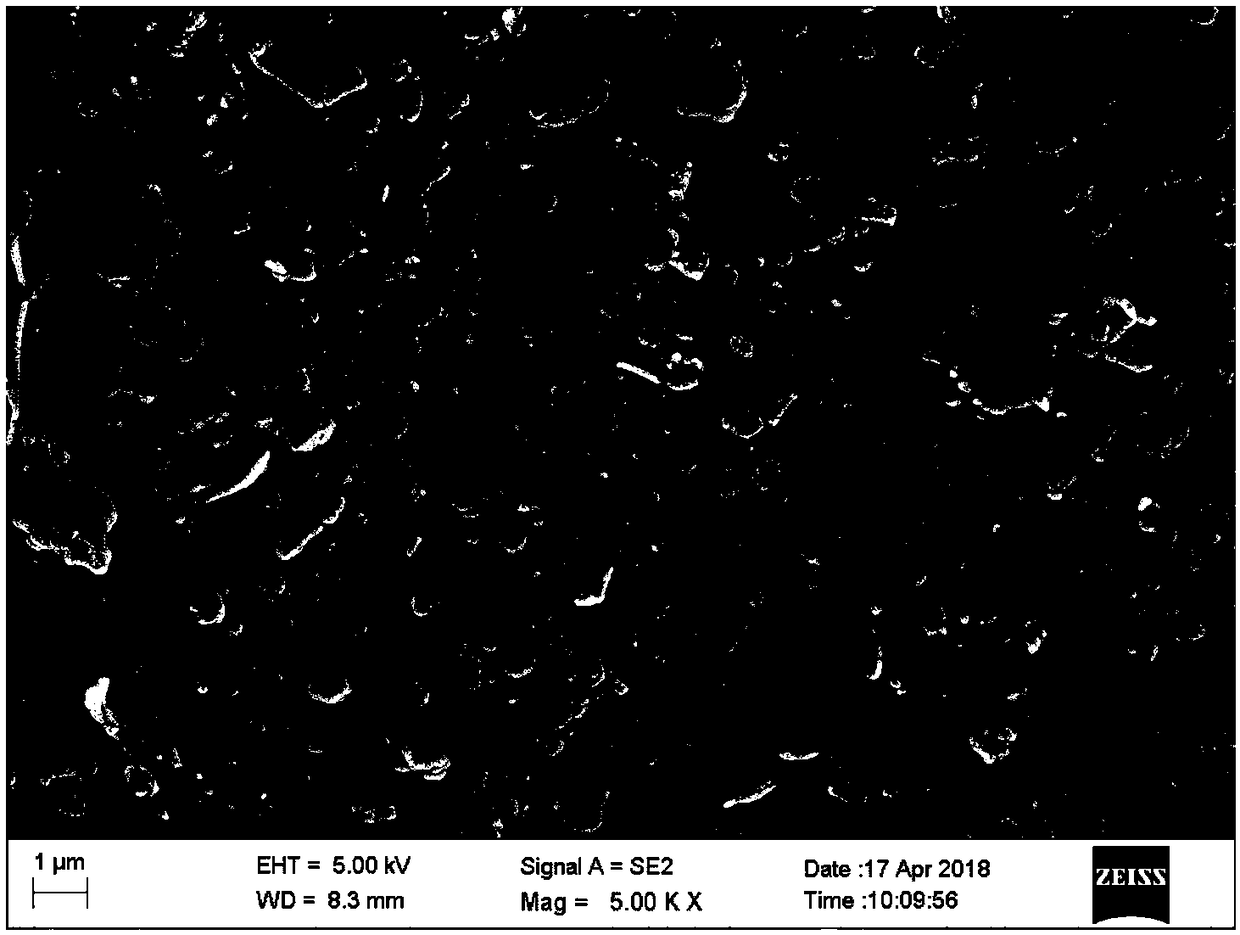

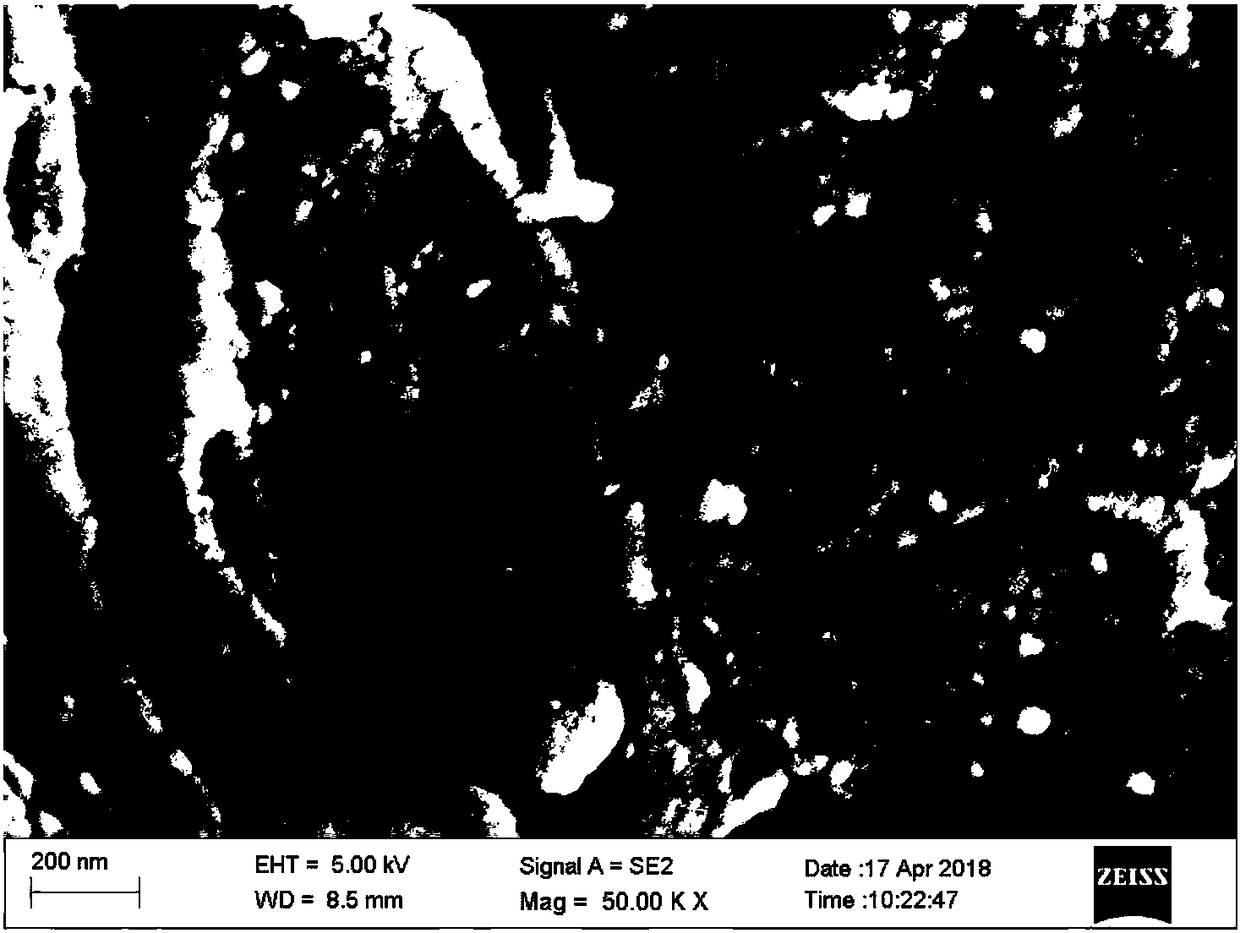

[0087] The present embodiment relates to a method for preparing porous carbon for supercapacitors based on garlic waste, comprising the steps of:

[0088] Step 1: Rinse the raw garlic seedlings with clean water to remove impurities, dry them at 105°C for 24 hours, crush them, and pass through an 80-mesh sieve.

[0089] Step 2: Take the garlic seedling powder obtained in Step 1 and place it in a tube furnace for carbonization at 600° C. for 2 hours. The protective gas is nitrogen, and the flow rate is 1 L / min. The heating rate was 5°C / min.

[0090] Step 3: Take the carbonized product obtained in Step 2 and 10wt% hydrochloric acid and place it in a water bath at 80°C for 30 minutes with magnetic force, then wash it with deionized water until it becomes neutral, and dry the obtained product in a blast drying oven at 105°C.

[0091] Step 4: Take the product obtained in Step 3 and mix it with KOH at a mass ratio of 1:4, and place it in an atmosphere muffle furnace for activation a...

Embodiment 2

[0095] The present embodiment relates to a method for preparing porous carbon for supercapacitors based on garlic waste, comprising the steps of:

[0096] Step 1: Rinse the garlic dregs raw material with clean water to remove impurities, dry at 105°C for 24 hours, pulverize, and pass through a 120-mesh sieve.

[0097] Step 2: Take the garlic seedling powder obtained in Step 1 and place it in a tube furnace for carbonization at 600°C for 2 hours. The protective gas is nitrogen, and the flow rate is 1.5 L / min. The heating rate is 10°C / min.

[0098] Step 3: Take the carbonized product obtained in Step 2 and 20wt% hydrochloric acid and place it in a water bath at 80°C for 30 minutes with magnetic force, then wash it with deionized water until it becomes neutral, and dry the obtained product in a blast oven at 105°C.

[0099] Step 4: Take the product obtained in Step 3 and mix it with KOH at a mass ratio of 1:5, and place it in an atmosphere muffle furnace for activation at 750°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

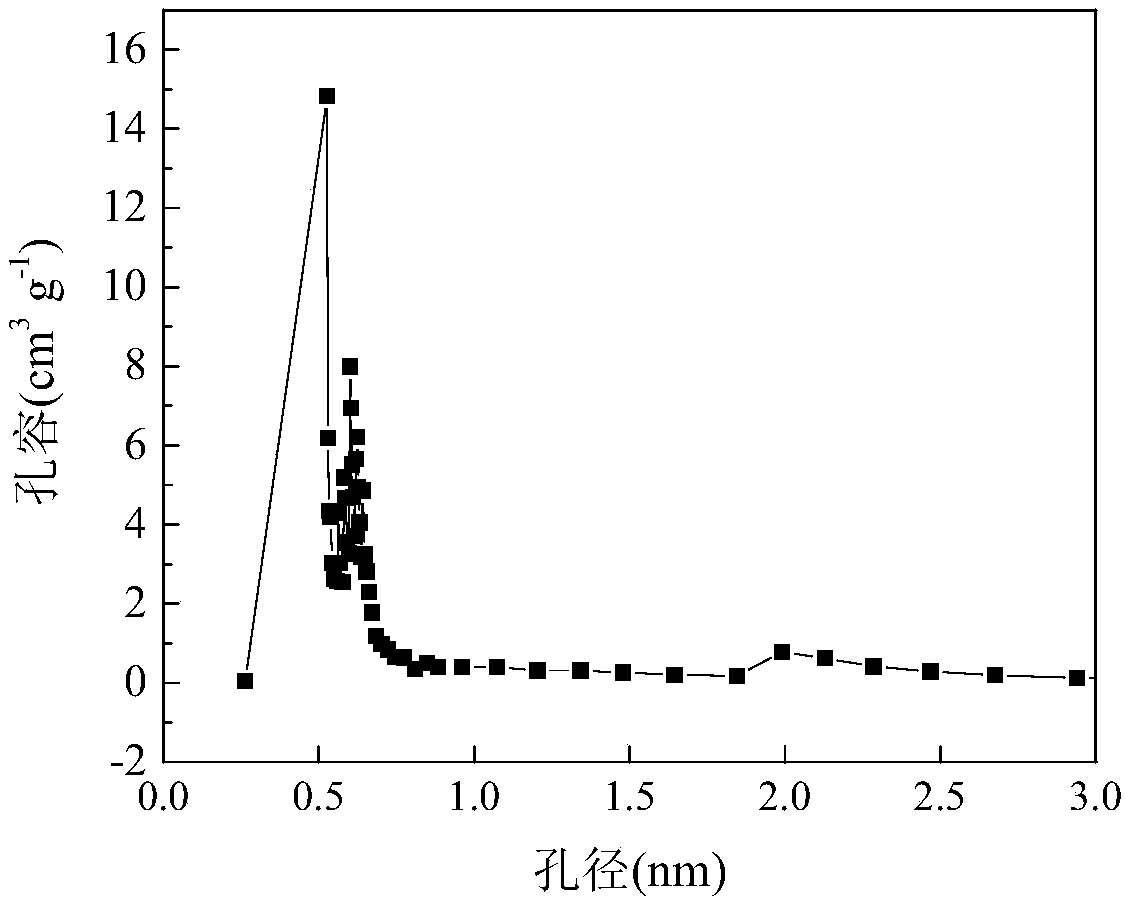

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com