A method for preparing activated carbon from dedusting ash emitted by iron and steel enterprises

A technology for preparing activated carbon and enterprises, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as large environmental impact, achieve the effects of protecting the environment, low production costs, and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

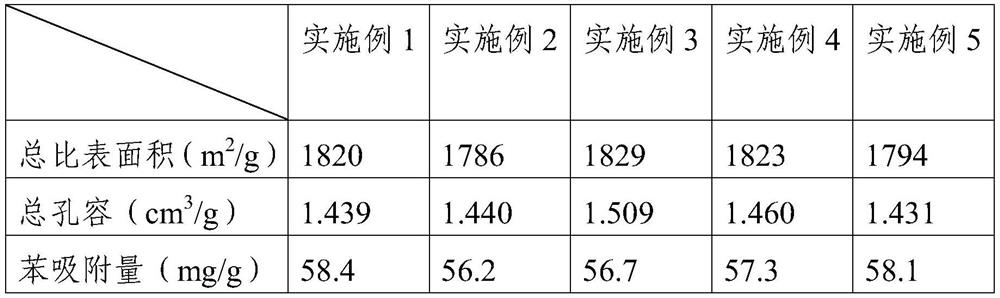

Examples

Embodiment 1

[0024] A kind of method utilizing the dedusting ash of iron and steel enterprise discharge to prepare active carbon, comprises the following steps:

[0025] (1) adding water to the dedusting ash to make a slurry, adding the slurry to the first-stage flotation machine and adding a hydrocarbon-based surfactant to carry out the first-stage flotation to obtain carbon powder with a higher carbon content;

[0026] (2) Add water to the carbon powder with higher carbon content to make slurry and add it to the secondary flotation machine, then add hydrocarbon-based surfactant to carry out secondary flotation to obtain carbon powder with high carbon content, which is dried, The drying temperature is 95°C;

[0027] (3) Mix the dried carbon powder with petroleum coke, grind it into powder, pass through a 400-mesh sieve, add water to the reactor, heat to 85°C and stir for 5 hours, filter, dry the solid at 115°C, and then add it to the reactor , the total mass of carbon powder and petroleu...

Embodiment 2

[0030] A kind of method utilizing the dedusting ash of iron and steel enterprise discharge to prepare active carbon, comprises the following steps:

[0031] (1) adding water to the dedusting ash to make a slurry, adding the slurry to the first-stage flotation machine and adding a hydrocarbon-based surfactant to carry out the first-stage flotation to obtain carbon powder with a higher carbon content;

[0032] (2) Add water to the carbon powder with higher carbon content to make slurry and add it to the secondary flotation machine, then add hydrocarbon-based surfactant to carry out secondary flotation to obtain carbon powder with high carbon content, which is dried, The drying temperature is 98°C;

[0033] (3) Mix the dried carbon powder with petroleum coke, grind it into powder, pass through a 400-mesh sieve, add water to the reactor, heat to 82°C and stir for 4.5 hours, filter, dry the solid at 112°C, and then add it to the reactor Among them, the total mass of carbon powder ...

Embodiment 3

[0036] A kind of method utilizing the dedusting ash of iron and steel enterprise discharge to prepare active carbon, comprises the following steps:

[0037] (1) adding water to the dedusting ash to make a slurry, adding the slurry to the first-stage flotation machine and adding a hydrocarbon-based surfactant to carry out the first-stage flotation to obtain carbon powder with a higher carbon content;

[0038] (2) Add water to the carbon powder with higher carbon content to make slurry and add it to the secondary flotation machine, then add hydrocarbon-based surfactant to carry out secondary flotation to obtain carbon powder with high carbon content, which is dried, The drying temperature is 90°C;

[0039] (3) Mix the dried carbon powder with petroleum coke, grind it into powder, pass through a 400-mesh sieve, add water to the reactor, heat to 80°C and stir for 4 hours, filter, dry the solid at 110°C, and then add it to the reactor , the total mass of carbon powder and petroleu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com