Lifting device for electrophoresis production line

A hoisting device and production line technology, which is applied in electrophoretic coating, electrolytic coating, transportation and packaging, etc., can solve the problems of poor electrophoresis effect of parts, reduction of electrophoresis quality of parts, easy precipitation of electrophoretic liquid at the bottom of the pool, etc., so as to avoid precipitation, The effect of improving the effect of electrophoresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

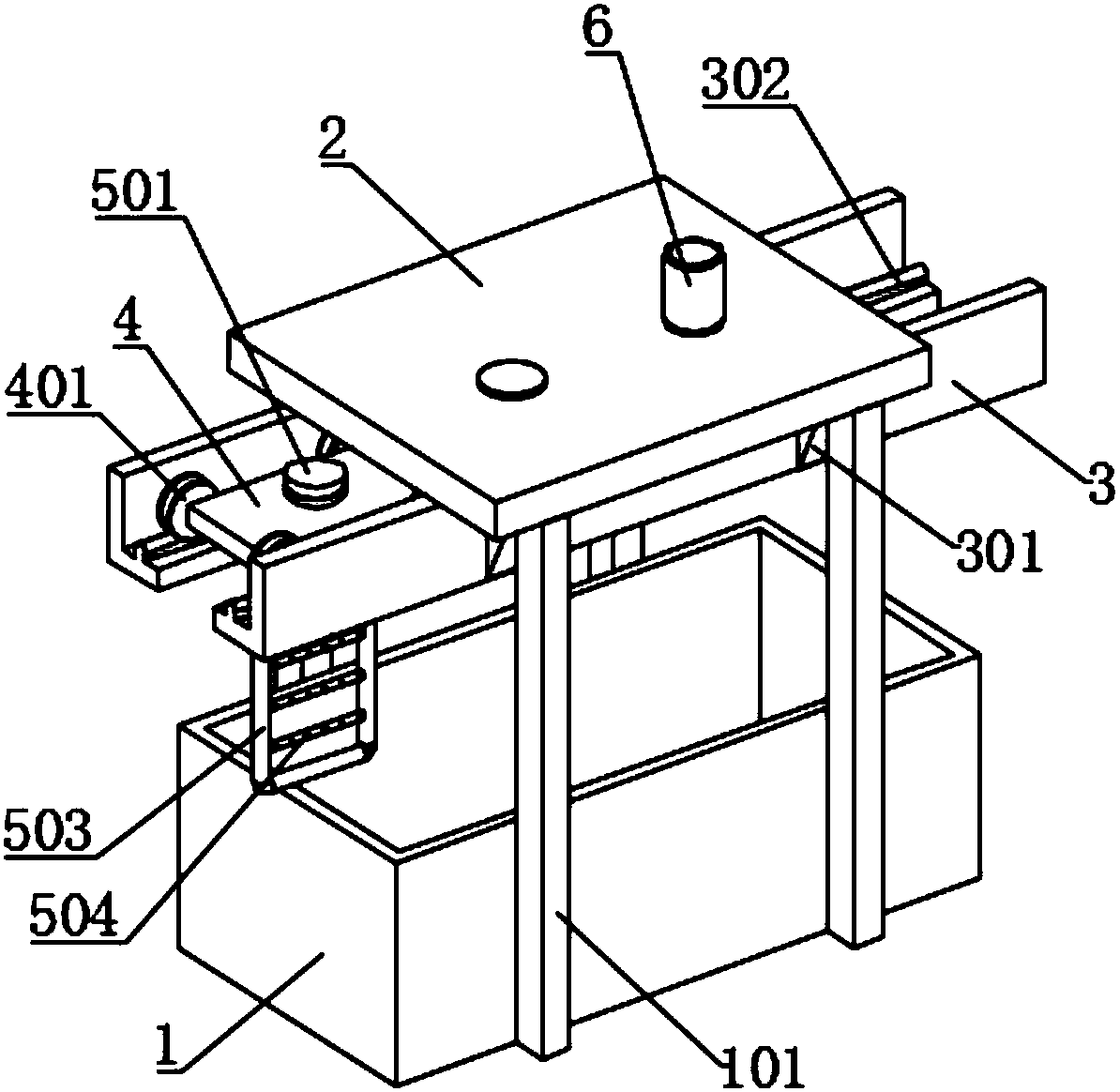

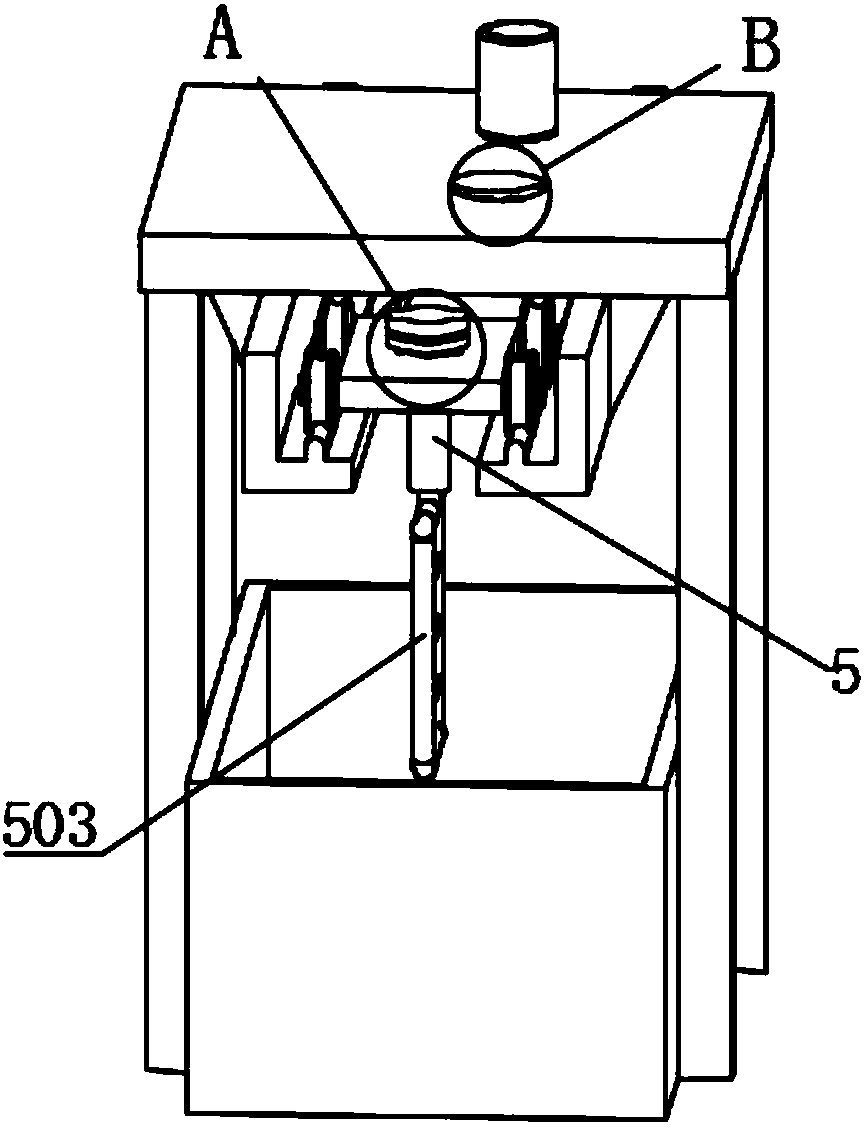

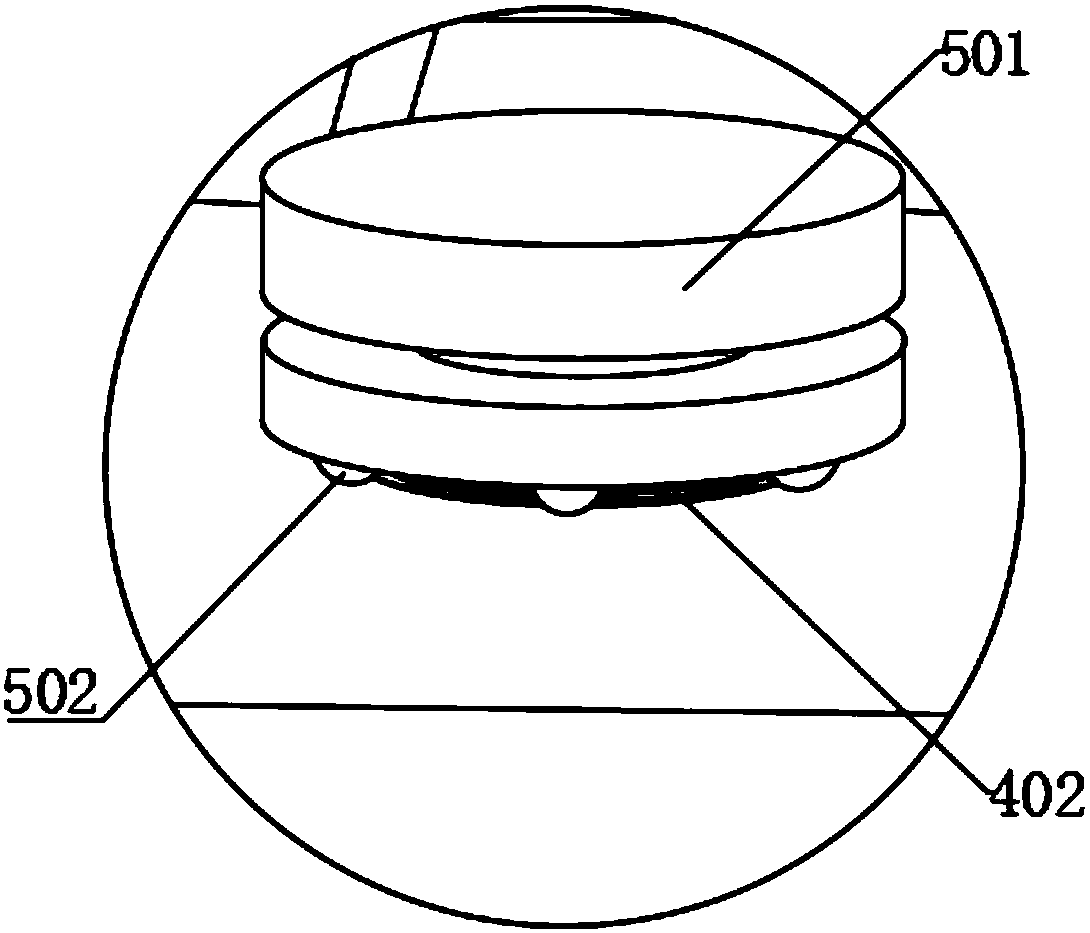

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a hoisting device for an electrophoresis production line, including an electric swimming pool 1, a pillar 101, a top plate 2, a bushing A201, an L-shaped conveying line 3, a rib 301, a track 302, a conveying vehicle 4, a conveying wheel 401, and a bushing B402 , electric cylinder 5, limit plate 501, ball A502, hoisting frame 503, hanging hole 504, motor 6, I-type turn block A601, connecting belt 7, auxiliary turn plate 8, ball B801 and I-type turn block B802; Four sets of pillars 101 are welded at both ends of the exterior of the electric swimming pool 1, and the top of the pillars 101 is connected to the top plate 2, and the bottom of the top plate 2 is welded with two sets of L-shaped conveying lines 3, and the outside of the L-shaped conveying line 3 is connected to the top plate There is also a rib 301 connected between the bottom end surfaces of 2, and the conveying vehicle 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com