Full sea deep hydraulic mechanical wrist joint

A technology of hydraulic machinery and wrists, which is applied in the field of full-sea deep hydraulic mechanical wrist joints, can solve the problems that cannot meet the specifications and use requirements of full-sea deep hydraulic manipulators, is not suitable for full-sea deep working conditions, and has a large minimum stable speed. Easy and fast replacement, compact structure, stable and low speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following examples can make those skilled in the technical field understand the present invention more comprehensively, but do not limit the present invention in any way.

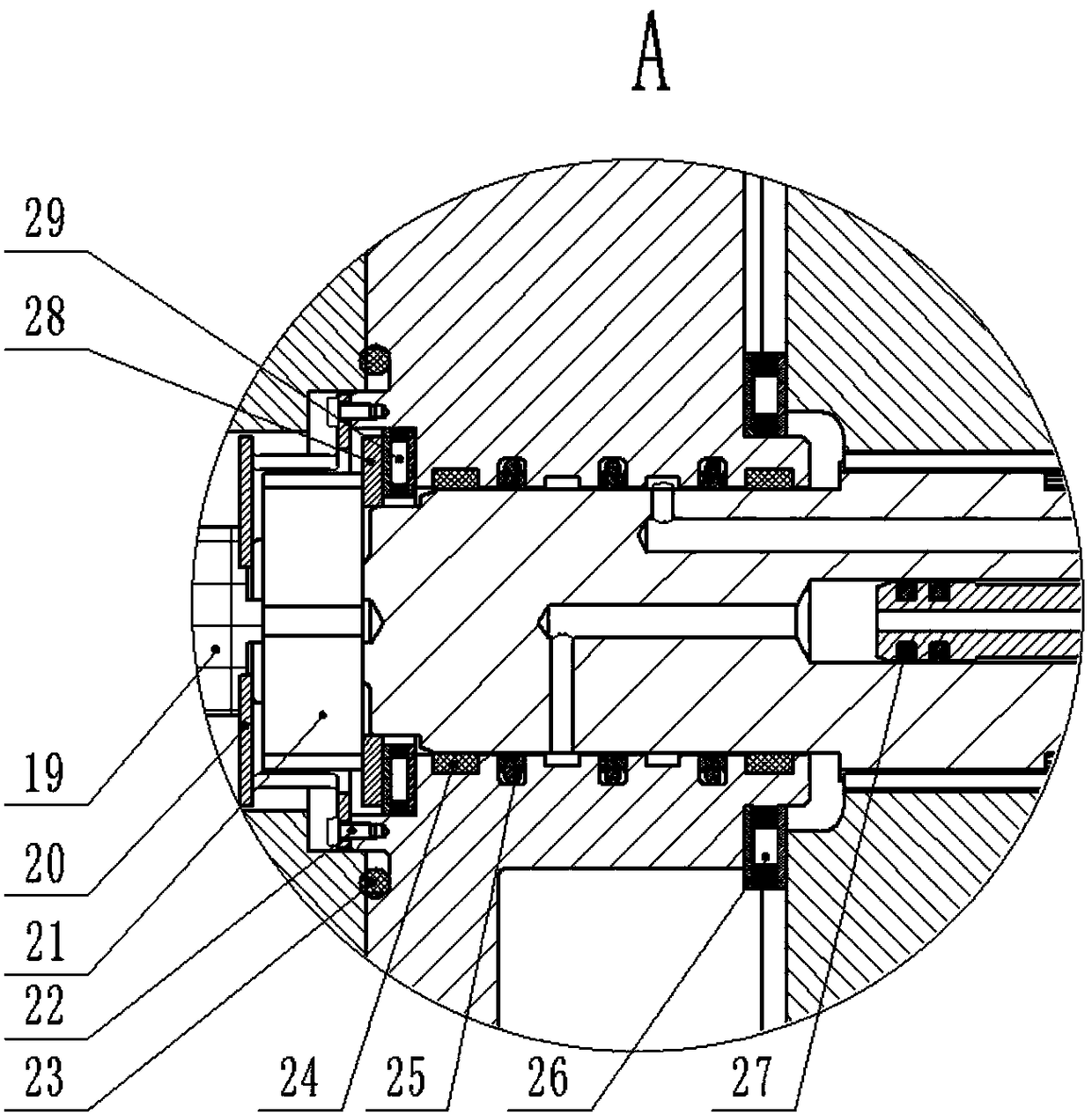

[0052] The present invention provides a specific embodiment of a full-sea deep hydraulic mechanical wrist joint, which includes three parts: a wrist motor, a claw cylinder, and a replaceable claw, wherein the wrist motor realizes the rotation of the claw, angle measurement and the structure of the claw cylinder The flow is distributed, and the claw cylinder drives the opening and closing of the claw to realize the grasping and releasing of the target.

[0053] Such as Figure 1-Figure 5 As shown: the wrist motor includes a motor front-end flow distribution block 1, a motor front-end cover 3, a motor end-face flow distribution plate 4, a multi-function internal curve radial plunger hydraulic motor housing 8, a motor rear end cover 9, a motor output shaft 10, and a plane Thrust needle roller beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com