Rotation control valve, rotation hydraulic system and engineering machine

A technology for controlling valves and rotary pumps, applied in mechanical equipment, cranes, fluid pressure actuating devices, etc., can solve the problems of no action of the main reversing valve core, no speed regulation, etc., and achieve large speed regulation range, low The effect of steady speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the essence of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0014] The invention provides a slewing control valve and a slewing hydraulic system, which are especially suitable for truck cranes.

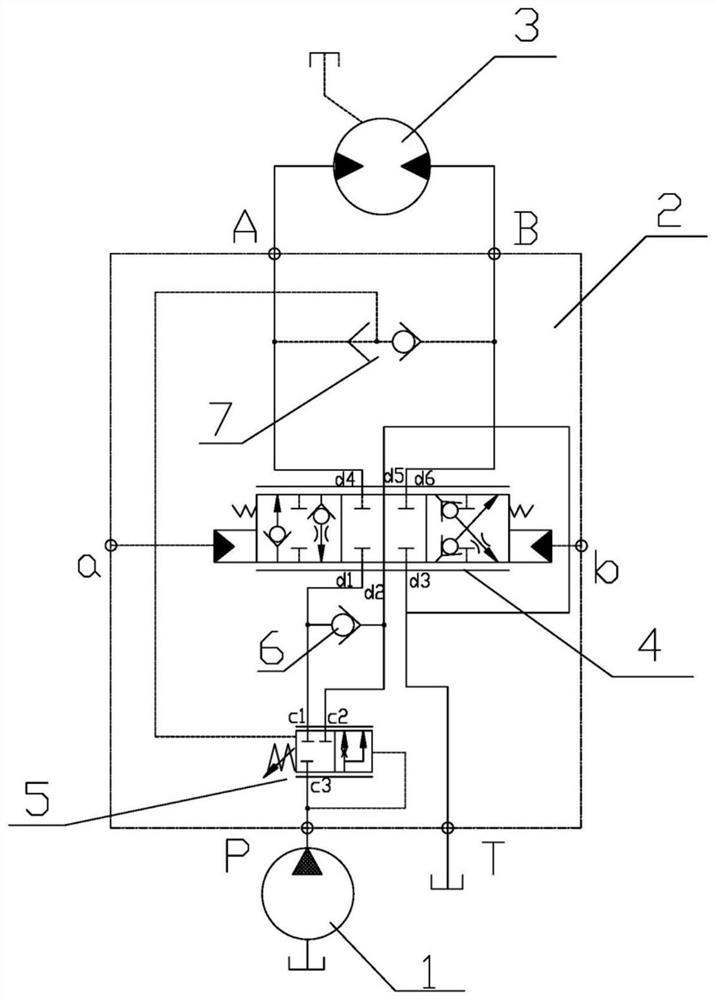

[0015] Such as figure 1 As shown, the swing control valve 2 includes a main reversing valve 4, a relief valve, a charge check valve 6 and a shuttle valve 7. The relief valve is a fixed difference relief valve 5, wherein ports c1 and c2 are oil outlets, and port c3 is an oil inlet.

[0016] The main reversing valve 4 is a hydraulically controlled three-position six-way reversing valve, wherein a and b are control ports, ports d1 and d2 are oil inlets; ports d4 and d6 are oil outlets. The d1 port and the d2 port are respectively connected with the c1 port and the c2 port of the differential overflow valve 5 . Outside the main reversing valve 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com