Processing technology of lamp mold parts

A technology for parts processing and automotive lamp molds is applied in the processing field of injection mold parts for automotive lamps, which can solve the problems affecting the finishing efficiency and accuracy of injection mold parts, difficult to meet the processing needs of high-hardness materials, and unsatisfactory processing effects. The effect of reducing processing cost, improving tool force, and avoiding tool breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

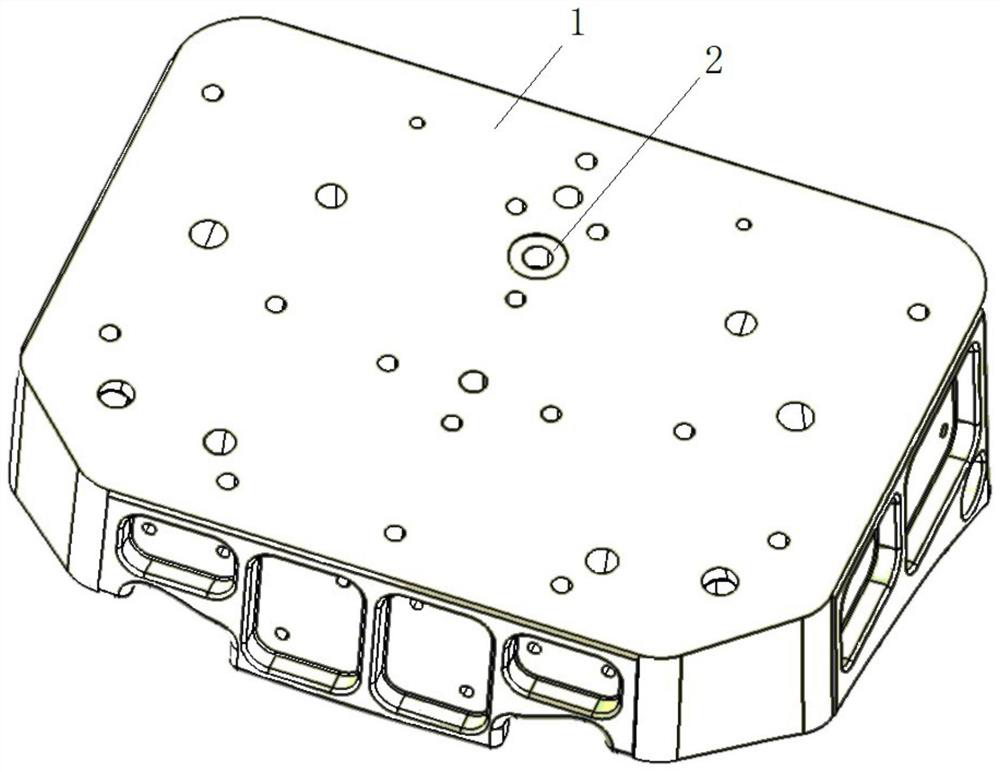

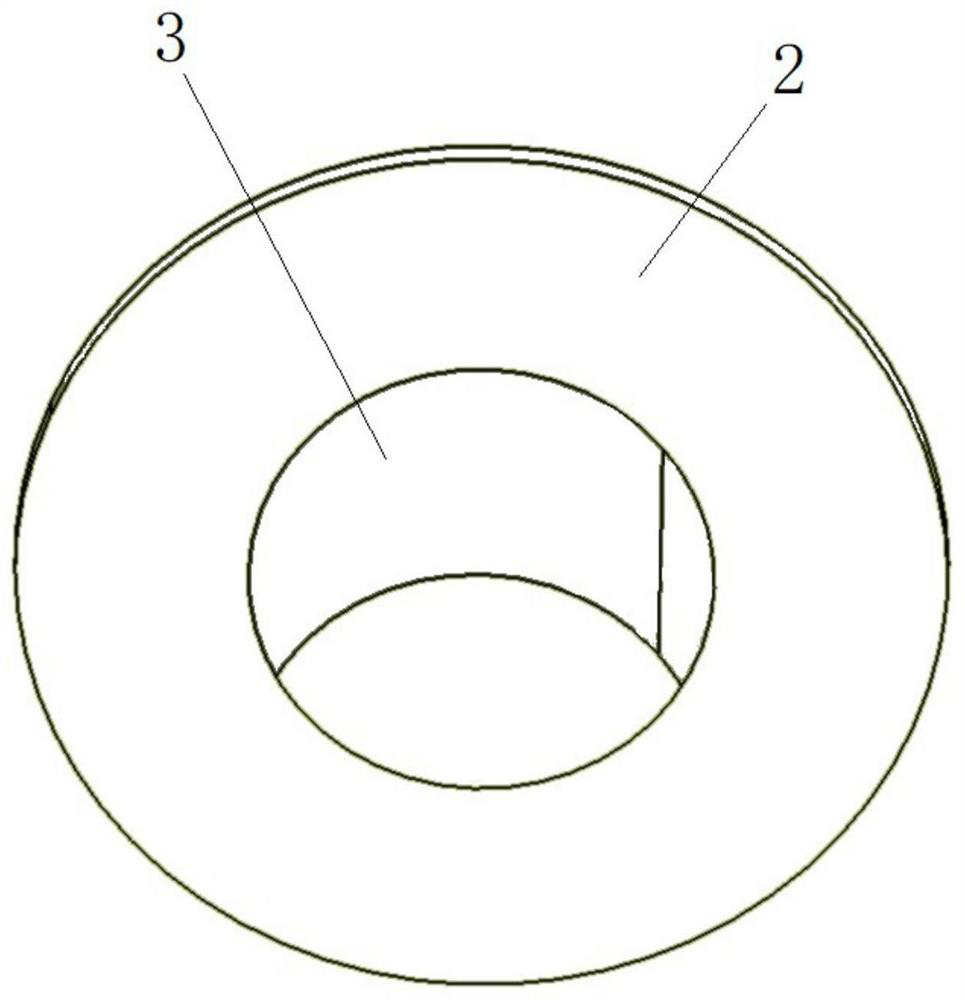

[0024] The invention discloses a processing technology for automotive lamp mold parts, which is mainly aimed at high-hardness parts such as inserts, cores and inner and outer core pulls. Surface machining is required before and after heat treatment. Considering the processing after heat treatment and the deformation during heat treatment, the machining before heat treatment should leave a good margin. After heat treatment, the hardness of the material is significantly improved, and the tool used for machining should use a tool whose hardness is 5-10 units of Rockwell hardness higher than that of the mold material. For example, for a workpiece with a hardness of about HRC50, it is preferable to use a tool with a hardness of about HRC55, so as to obtain better processing quality and higher processing efficiency, while taking into account the tool life and use cost.

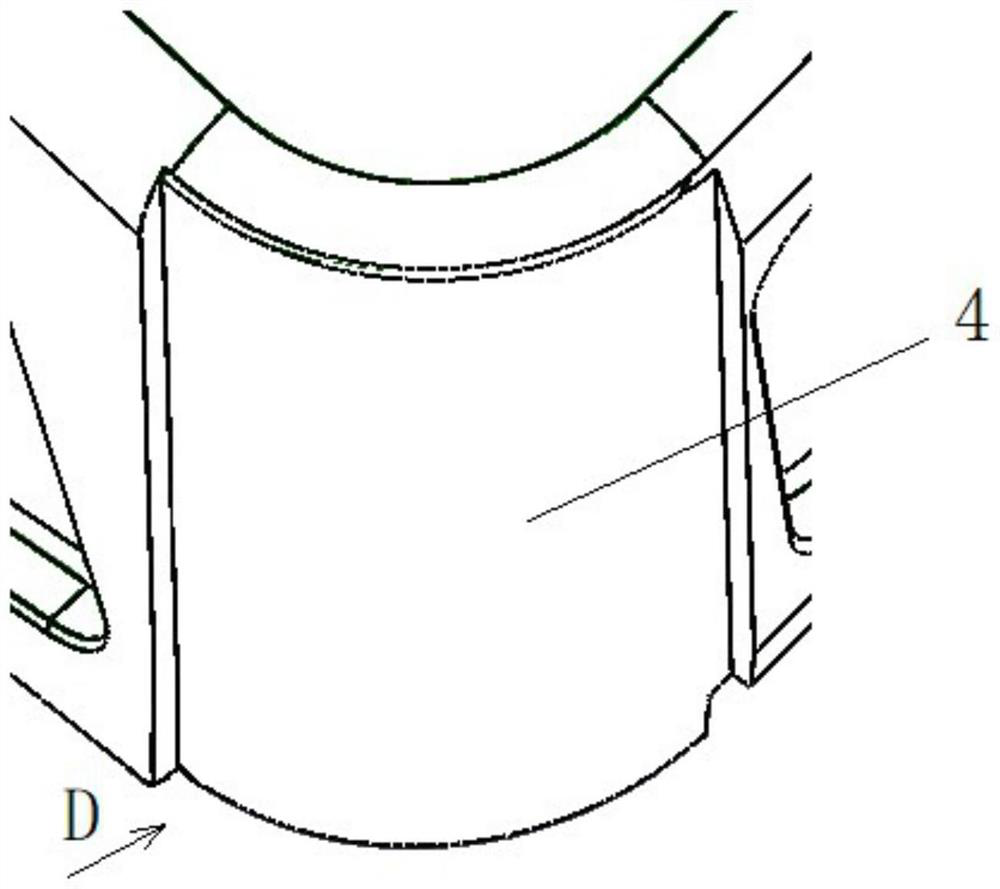

[0025] After heat treatment, the surfaces of the workpiece are mainly processed by milling. It is preferred to u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com