Explosion valve tension bolt weakening groove surface ultrasonic impact treatment device and working method thereof

A technology of ultrasonic impact and treatment device, which is applied in the field of peripheral groove surface strengthening device of shaft parts, to achieve the effect of easy monitoring and adjustment, less parameters and no pollution to the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

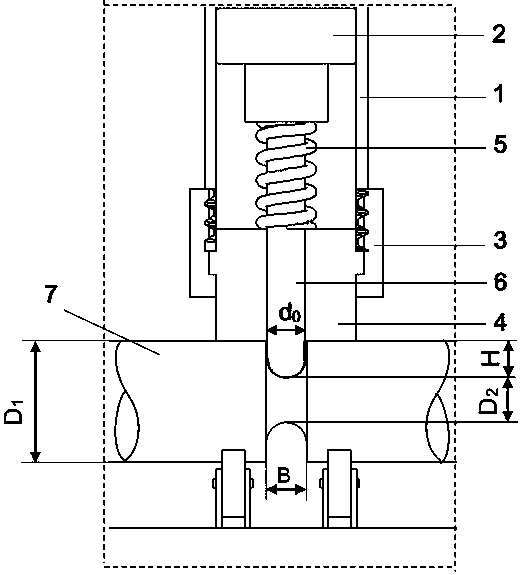

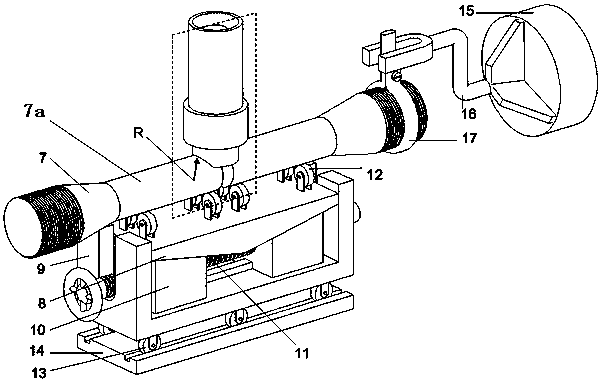

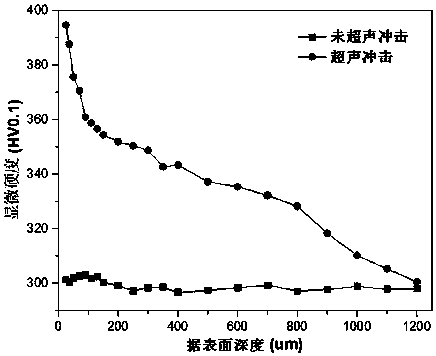

[0031] Surface strengthening treatment was carried out on the weakening groove of tension bolt of a certain type of blasting valve. The dimensions of the weakening groove of the tension bolt of the blasting valve are as follows: diameter of the working section of the blasting valve D 1 is 37 mm, the diameter of the thinnest part of the weakened groove is D 2 is 20 mm, the depth H of the weakened groove is 8.5 mm, the width B of the weakened groove is 8 mm (the size tolerance is +0.5-+0.2mm), and the "hyperboloid alignment" at the bottom of the weakened groove is a semicircle with a radius of 4 mm. The lower end surface of the guide sleeve used is a circular arc surface with a curvature radius R of 16.5 mm matching the working section of the tension bolt, and the diameter of the lower section of the impact needle is d 0 It is 8 mm (dimension tolerance is +0--0.1mm), slightly smaller than the width B of the weakened groove, so as to ensure that the impact needle can move freely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com