T-pipe bulging forming device and bulging forming method for branch pipe of T-pipe

A three-way tube and bulging technology, which is applied in the field of three-way tube bulging forming devices, can solve the problems of poor uniformity of wall thickness at the forming part, high control accuracy and difficulty in operation, large deformation of local bulges, etc. Convenience and reliability, increased efficiency and synergistic continuity, less breakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

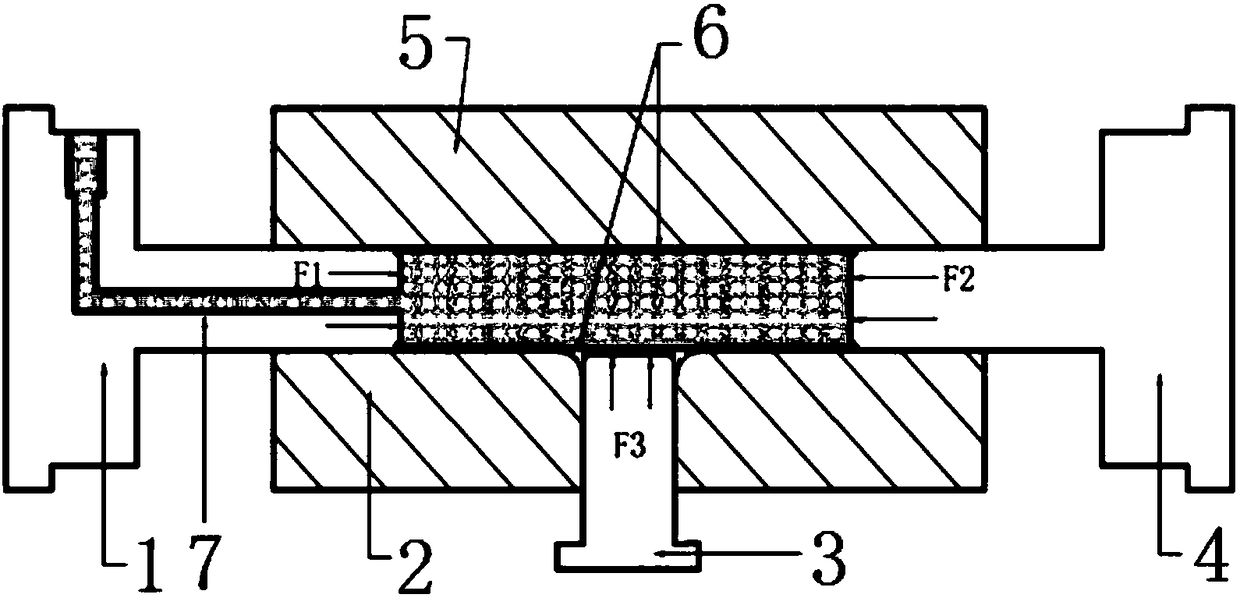

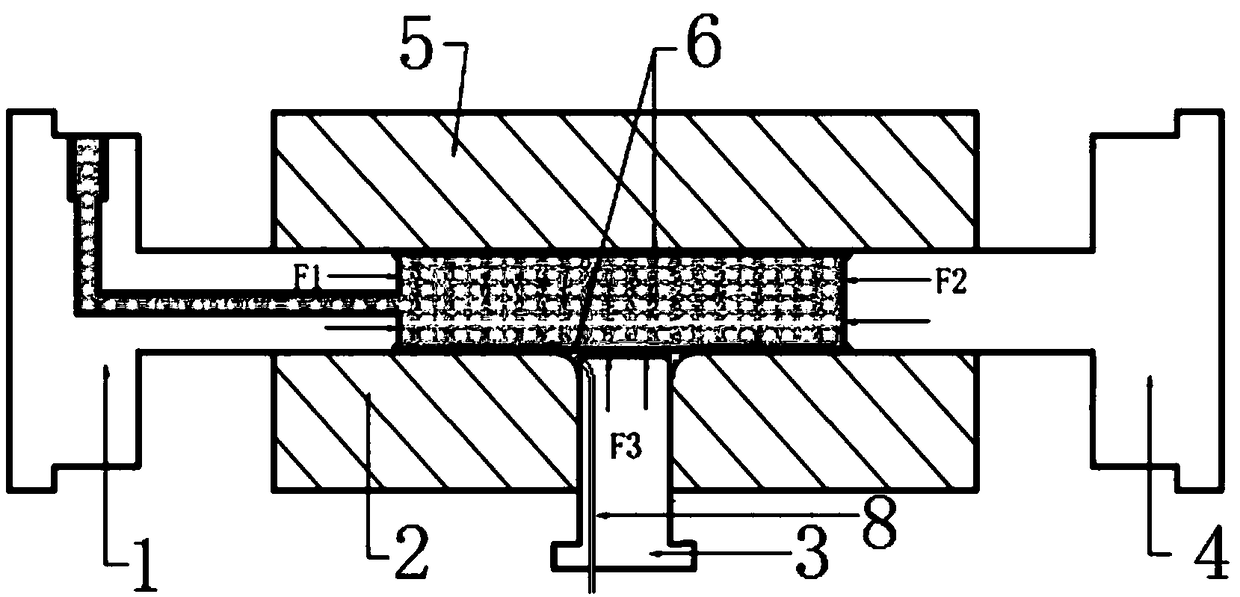

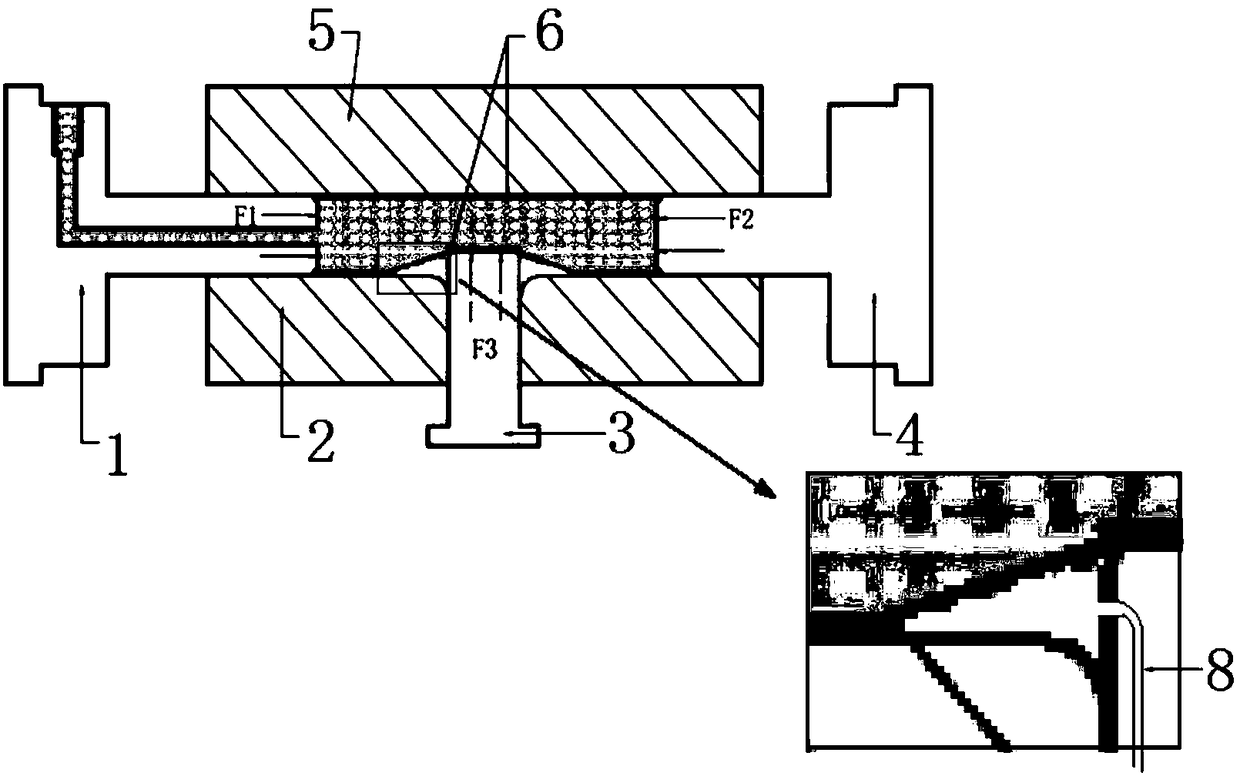

[0029] like Figure 1-4 As shown, the present invention is realized in such a way that the three-way pipe bulging forming device at least includes a mold, a pressure medium injection device, a pressure pushing head device, a cylinder jacking device, a pressure sensor, a displacement sensor and a controller, wherein the pressure medium The injection device is used to inject pressure medium into the tube blank 6 in the mold cavity; the pressure pusher device is used to squeeze the end of the tube blank and the pressure medium, and the pressure medium generates pressure to make the tube blank 6 expand and form; the jacking device and The bulging part of the branch pipe on the tube blank 6 contacts and exerts force during the bulging and forming of the branch pipe; the pressure sensor is used to detect the pressure of the pressure medium; the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com