Electric heating smoking device with heat distribution function

A technology of dispensing function and smoking device, which is applied in the directions of smoker's products, tobacco, and application, can solve the problems of poor smoking feeling, easy curing, uneven heating of electric heating cigarettes, etc., so as to reduce the difficulty of production and prevent excessive temperature. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

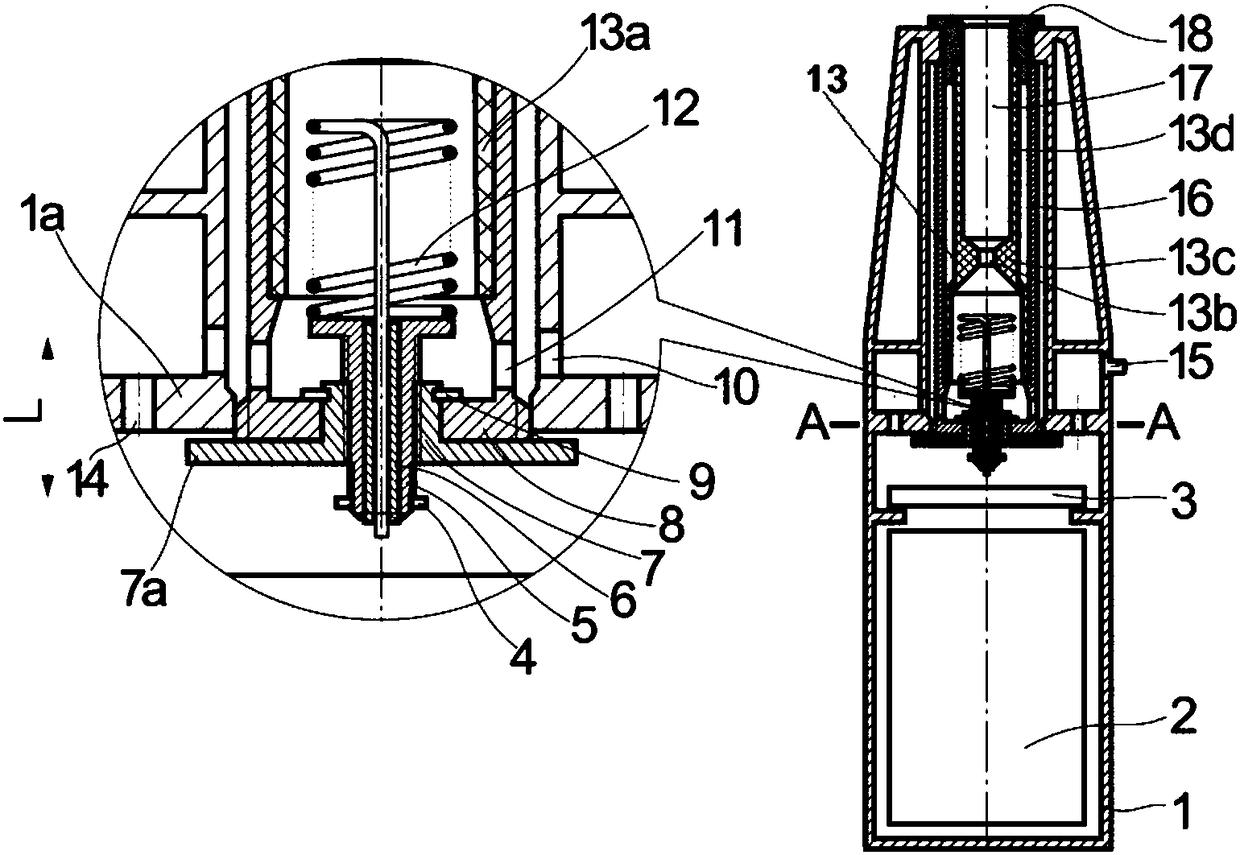

[0041] An electric heating smoking device with heat distribution function, which includes the following components:

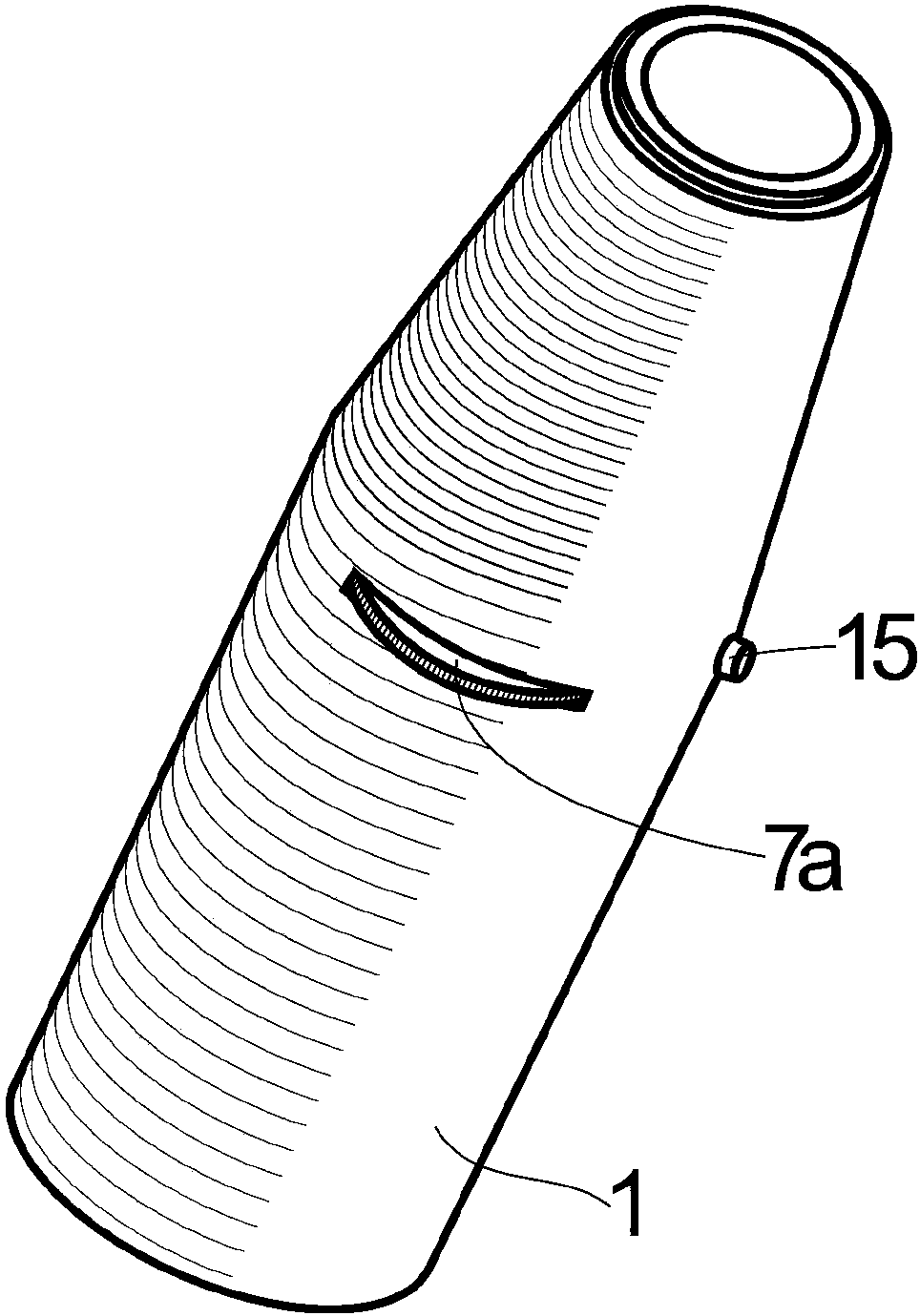

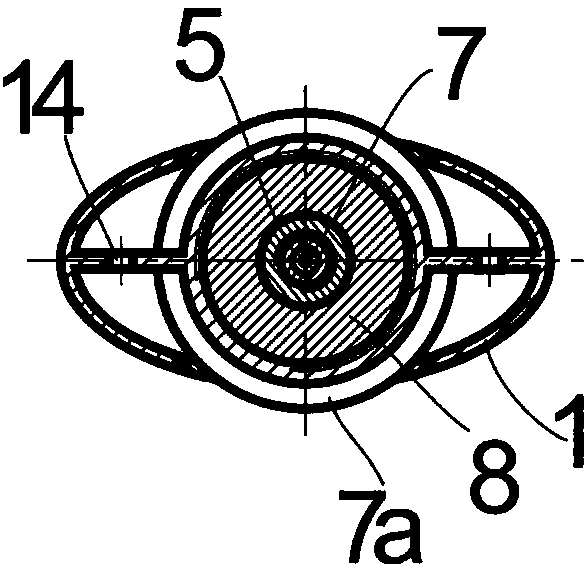

[0042] The shell 1 has an air intake hole on it, and it includes a rib plate 1a, and the rib plate 1a is provided with a first ventilation hole 14;

[0043] Insulation pipe 16, which is located in the shell 1, has a third vent hole 11 on its side wall, and the heat insulation pipe 16 is detachably installed on the heat insulation pipe base 8 with a cavity. The pipe base 8 is detachably installed on the rib plate 1a;

[0044] Venturi tube type heat storage pipe 13, which is located in the cavity of the heat insulation pipe 16, and includes: a gas collecting pipe 13a and a preheating pipe 13d, and the gas collecting pipe 13a and the preheating pipe 13d pass through the heat storage body The straight heating throat 13b surrounded by 13c is air-connected and connected, the cavity of the preheating pipe 13d is the cigarette accommodating cavity 17, and the cavity o...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the height adjustment mechanism of the heating wire 12 is simplified, and the matching with the cigarette to be smoked is realized by selecting the size of the heat storage body 13c.

[0055] The working principle of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that: the venturi tube type heat storage tube has increased the horizontal hot throat 13e and the stopper 13f, by adding the horizontal hot throat and the stopper, the hot air heated by the heating wire can be avoided from directly It enters the straight heat throat to prevent the hot air from being too fast and the heat is too high to burn the shredded tobacco. On the other hand, it can better store more heat in the heat storage body and transfer it to the relatively low temperature preheating tube , to achieve full preheating of cigarettes.

[0058] The working principle of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com