Inner valve of a cast-in-place large pipe pile hole forming device and its application method

A technology of large pipe piles and hole formers, which is applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of insufficient structural strength and valve sealing, so as to enhance the sealing performance and stability of the connection and enhance the bearing capacity. Pressure capacity, reducing deformation and dislocation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

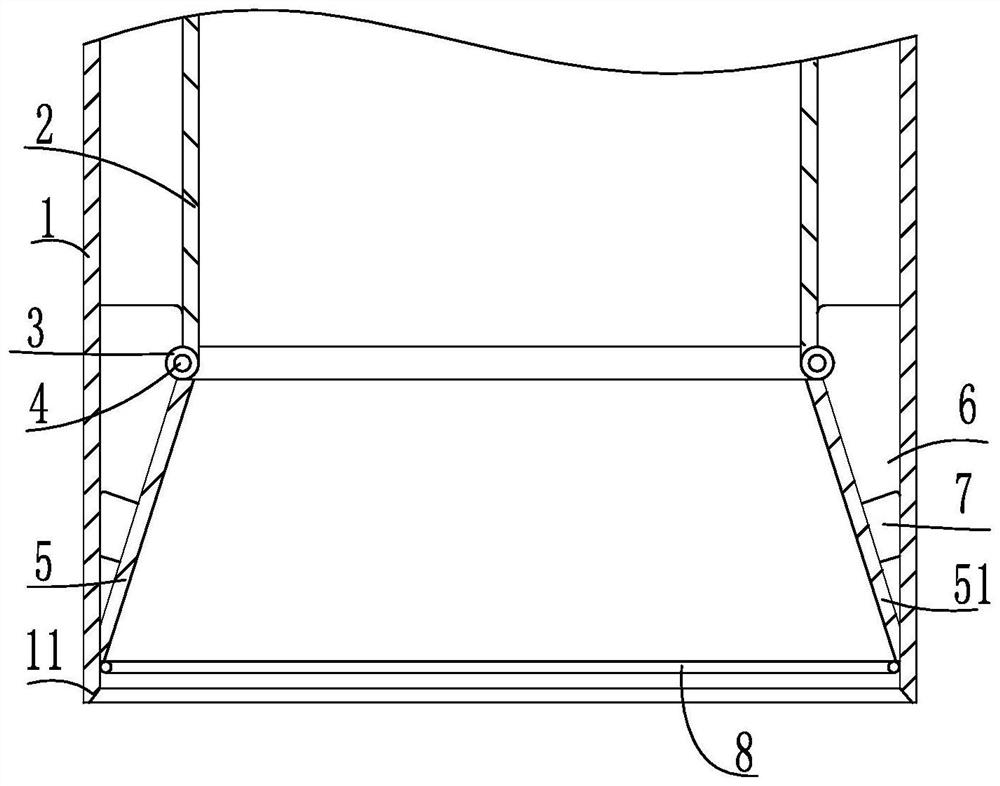

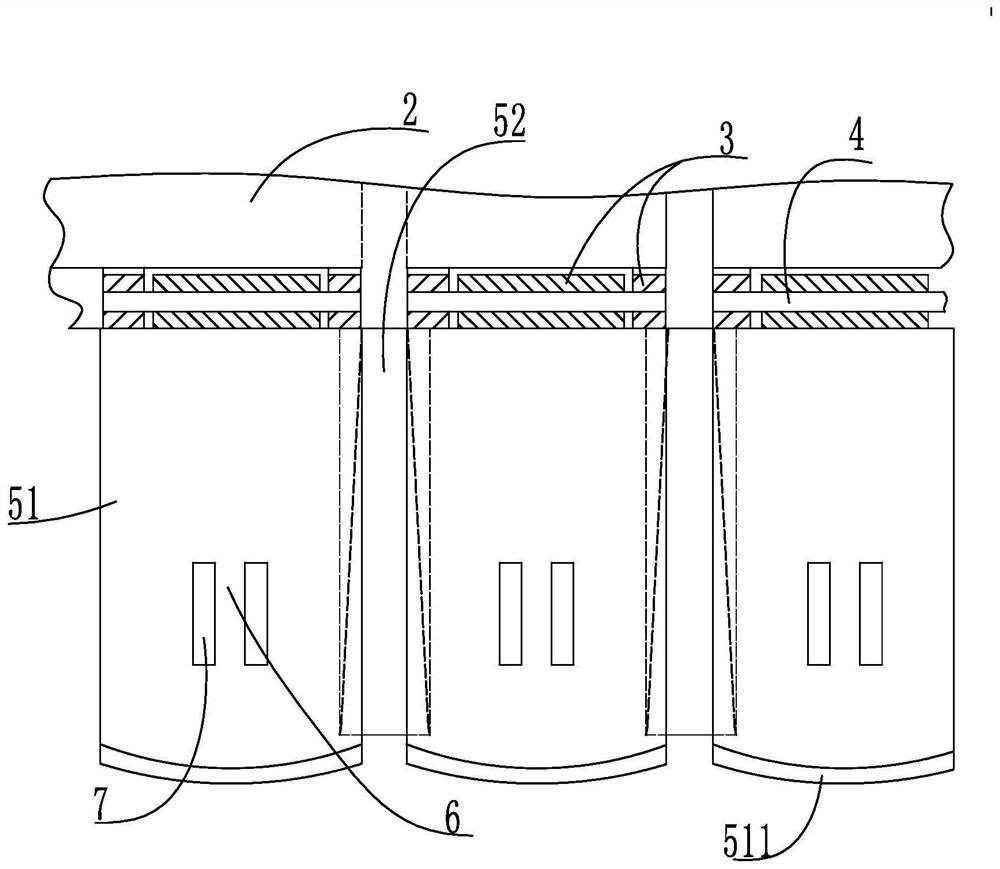

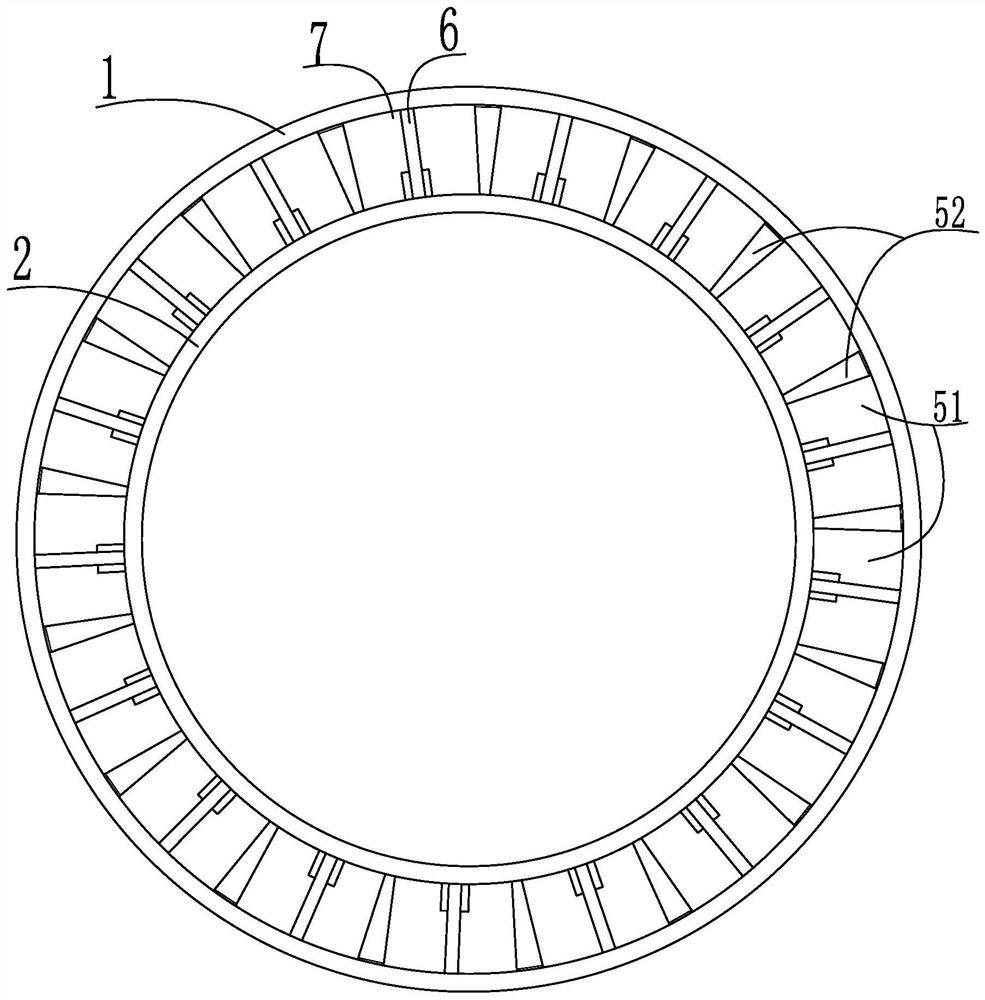

[0039] Figure 1 to Figure 6 Among them, an internal valve of a cast-in-place large pipe pile hole former can be combined with a double-layer casing to form a pile form for a cast-in-place large pipe pile. The double-layer casing includes an inner pipe 2 and a shaft coaxial with the inner pipe 2 The outer tube 1 and the inner valve include several valve units 51. The valve units 51 are cut and formed by the same circular platform. The upper end of the valve unit 51 is provided with a connecting sleeve 3, and the connecting sleeve 3 is provided with a mandrel 4. The mandrel The two ends of 4 are located outside the connecting sleeve 3 to form two connecting parts. The lower end of the inner tube 2 is provided with a matching sleeve matching the connecting part, and the valve unit 51 is rotatable through the connection between the mandrel 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com