Jean-like water-washed wool worsted fabric and production process thereof

A technology for worsted fabrics and production processes, applied in textiles and papermaking, etc., can solve problems such as difficulty, product specification limitations, and inappropriate wool dyeing, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated by the following examples: According to the following examples, the present invention can be better understood. However, those skilled in the art can easily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in the claims.

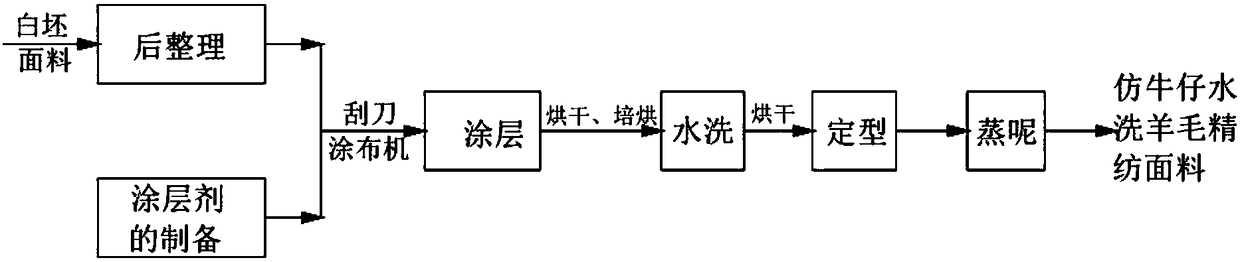

[0018] combine figure 1 As shown, the wool blended worsted white blank fabric with compact structure, smooth surface and no dyeing is selected. The white blank fabric adopts compact spinning technology, the ground weave is plain weave, and the side weave is 2 / 2 warp heavy flat. The yarn used is The raw material ratio is 58% of wool, 12% of flax and 30% of polyester. The white blank fabric is processed in the following order: raw repair, singeing, boiling, washing, boiling, drying, intermediate Inspection, shearing, trimming, brushing, pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com