Rubber injection method containing metal insert and mold

A technology of metal inserts and injection molds, applied in the direction of coating, etc., can solve the problems of manual removal of burrs, increase process, reduce efficiency, etc., achieve the effect of reducing waste and burrs, and eliminating glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

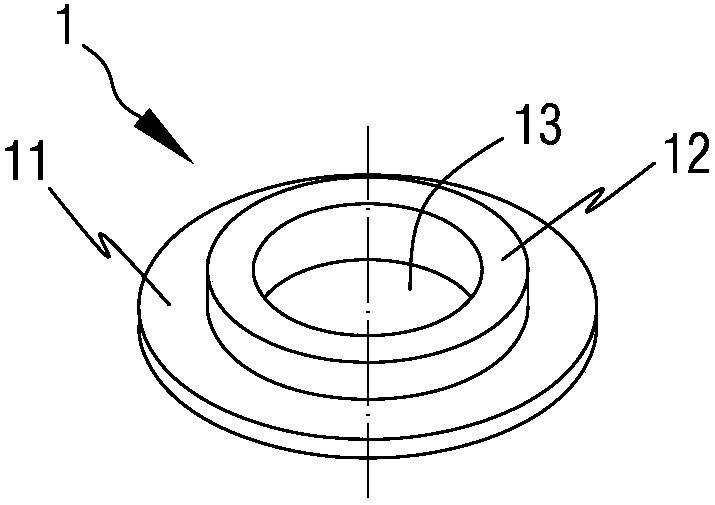

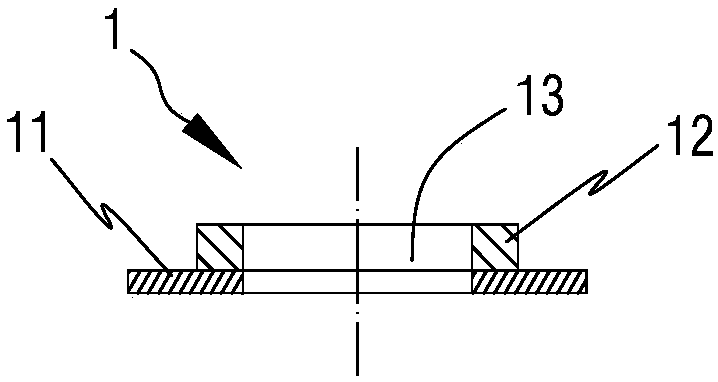

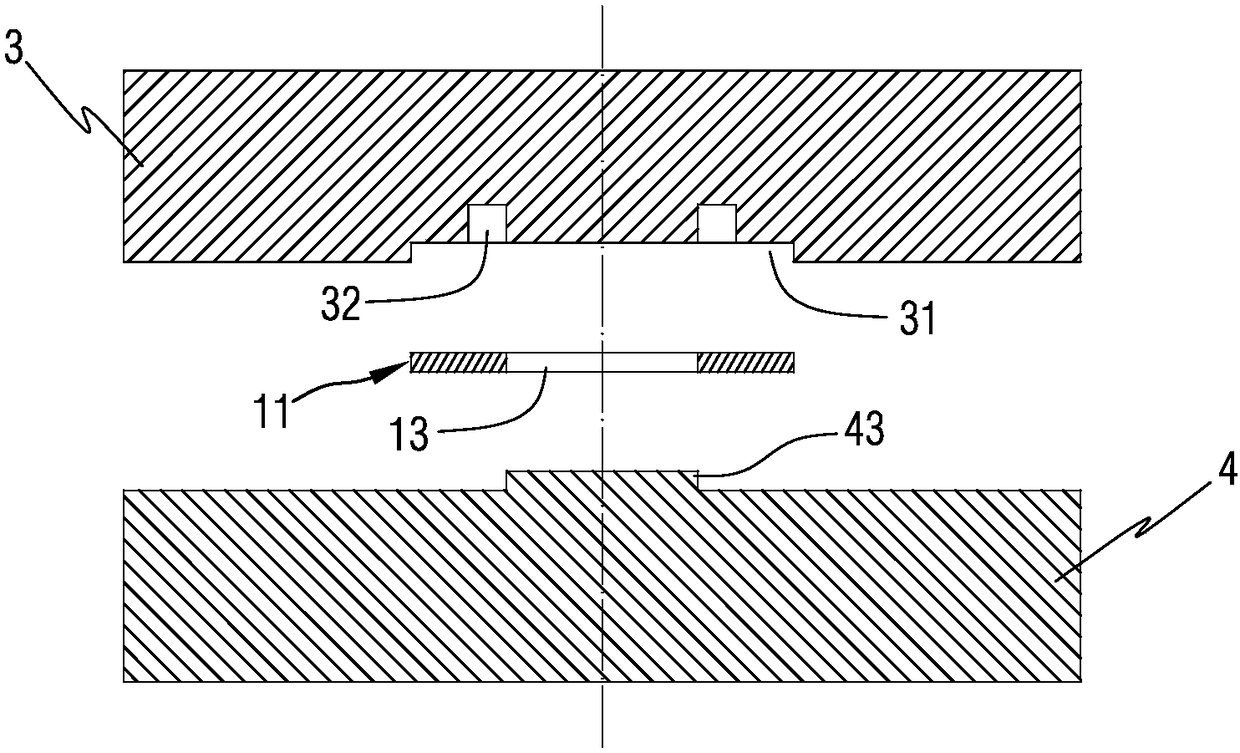

[0034] In view of the background section, similar to Figure 1-2 When the rubber injection molded parts containing metal inserts shown are injection molded by common processing technology, due to the different thickness of the metal inserts, there is a defect of overflowing glue, which leads to measures to remove the burrs after demoulding, which increases the process and reduces the efficiency. And the problem of overflow glue waste, the present invention proposes a kind of improved injection molding process and mould, as Figure 5-7 shown. in, Figure 5 Shown is a mold injection exploded schematic diagram of a rubber injection molded part containing a metal insert ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com