Power battery liquid heating system based on liquid cooling system and control method of power battery liquid heating system

A power battery and control method technology, applied in battery/fuel cell control devices, secondary batteries, control devices, etc., can solve the problem that the battery cannot be charged and discharged at a high rate, so as to improve energy utilization, reduce energy consumption, The effect of improving vehicle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

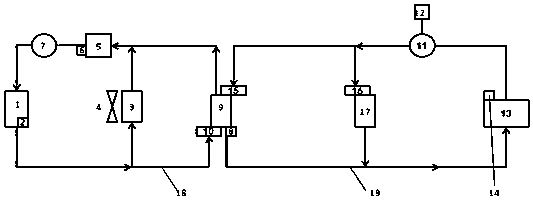

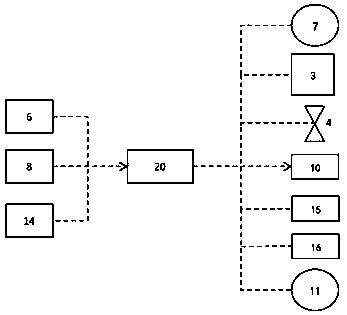

[0028] Please see attached figure 1 and attached figure 2 , a power battery liquid heat system based on a liquid cooling system, including an engine 1, a thermostat 2, a radiator 3, a fan 4, a water tank 5, a first water pump 7, a heat exchanger 9, a first solenoid valve 10, a second Second water pump 11, battery pack 13, second solenoid valve 15, third solenoid valve 16 and heater 17; engine 1, thermostat 2, first solenoid valve 10, heat exchanger 9, water tank 5, first water pump 7 Connect by engine pipeline 18 and form engine hot water circuit, engine 1, thermostat 2, radiator 3, water tank 5, the first water pump 7 are connected by engine pipeline 18 and form engine cooling circuit, one side of radiator 3 is installed with The fan 4, the engine hot water circuit and the engine cooling circuit share the engine 1, the thermostat 2, the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com