Packaging structure and packaging method of OLED device

A technology of packaging structure and packaging method, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of reduced service life of devices, poor water and oxygen barrier ability, and reduced service life of devices, so as to improve service life , Improve the effect of water and oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

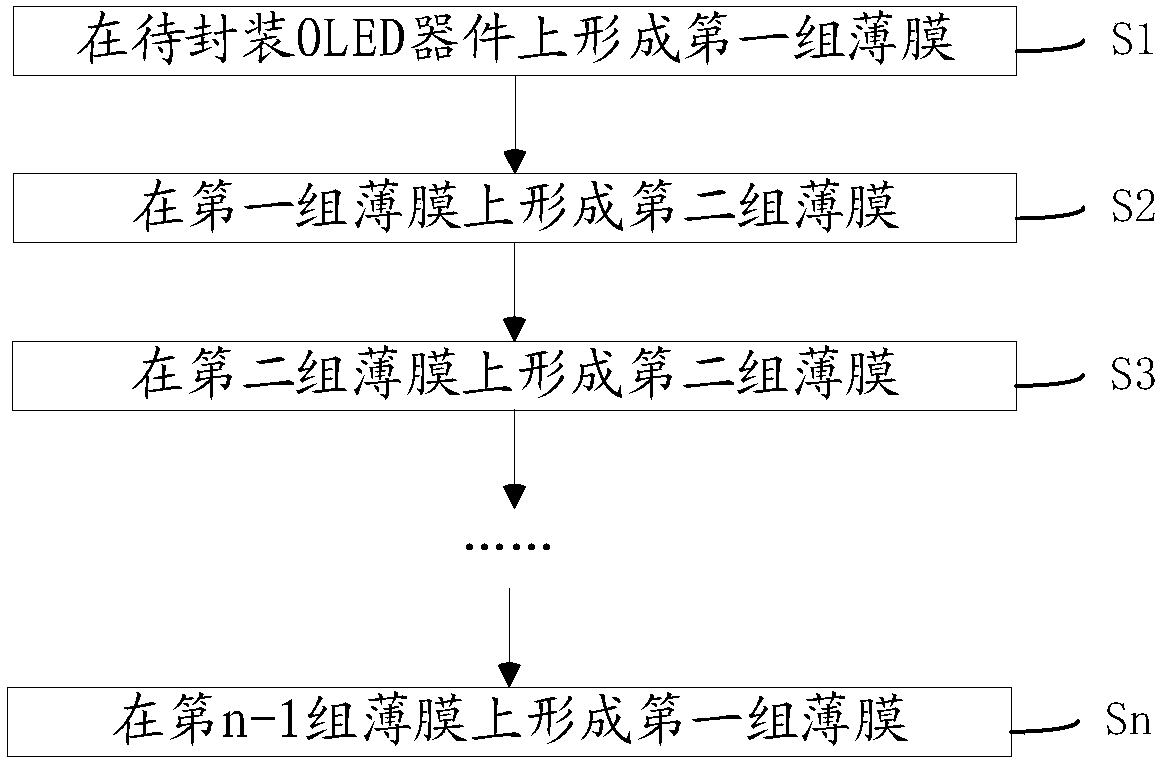

[0028] The liquid crystal display assembly provided by the embodiment of the present invention has been introduced in detail above. The principles and implementation modes of the present invention are explained by using specific examples in this paper. The description of the above embodiments is only for helping to understand the present invention. At the same time, for those skilled in the art, according to the idea of the present invention, there will be changes in the specific implementation and application scope. In summary, the content of this specification should not be construed as limiting the present invention. The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com