Light low-noise cable

A low-noise, cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve problems such as undesigned structures, and achieve the effects of increased weight, reasonable structural design, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

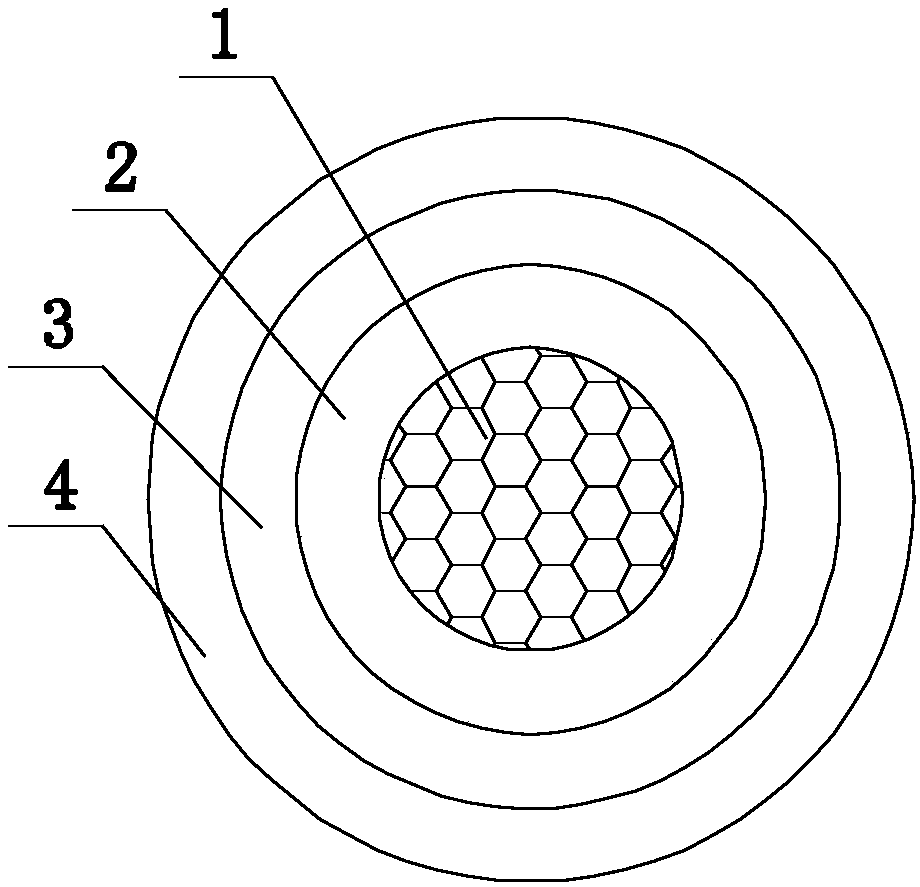

[0013] Such as figure 1 As shown, figure 1 It is a schematic diagram of the structure of a light-weight low-noise cable proposed by the present invention.

[0014] Reference figure 1 , A light-weight low-noise cable proposed by the present invention includes: a conductor 1, an insulating layer 2, a braided shielding layer 3, and a sheath layer 4;

[0015] Conductor 1 is made by twisting copper wires. The outer wall of conductor 1 is coated with the first semi-conductive glue. The insulating layer 2 covers the outside of the conductor 1 and is bonded to the conductor 1 through the first semi-conductive glue. The surface of the insulating layer 2 is coated with the first semi-conductive glue. With two semi-conductive adhesives, the braided shielding layer 3 covers the outside of the insulating layer 2 and is attached to the outer wall of the insulating layer 2 through the second semi-conductive adhesive, and the sheath layer 4 covers the outside of the braided shielding layer 3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com