Pipe shoe and manufacturing method thereof

A production method and technology of pipe shoes, which are applied to pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as pollution of the marine environment, pipe deformation and wear, safety accidents, etc., to ensure safety and stability, Increase the buffer strength and the effect of good contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

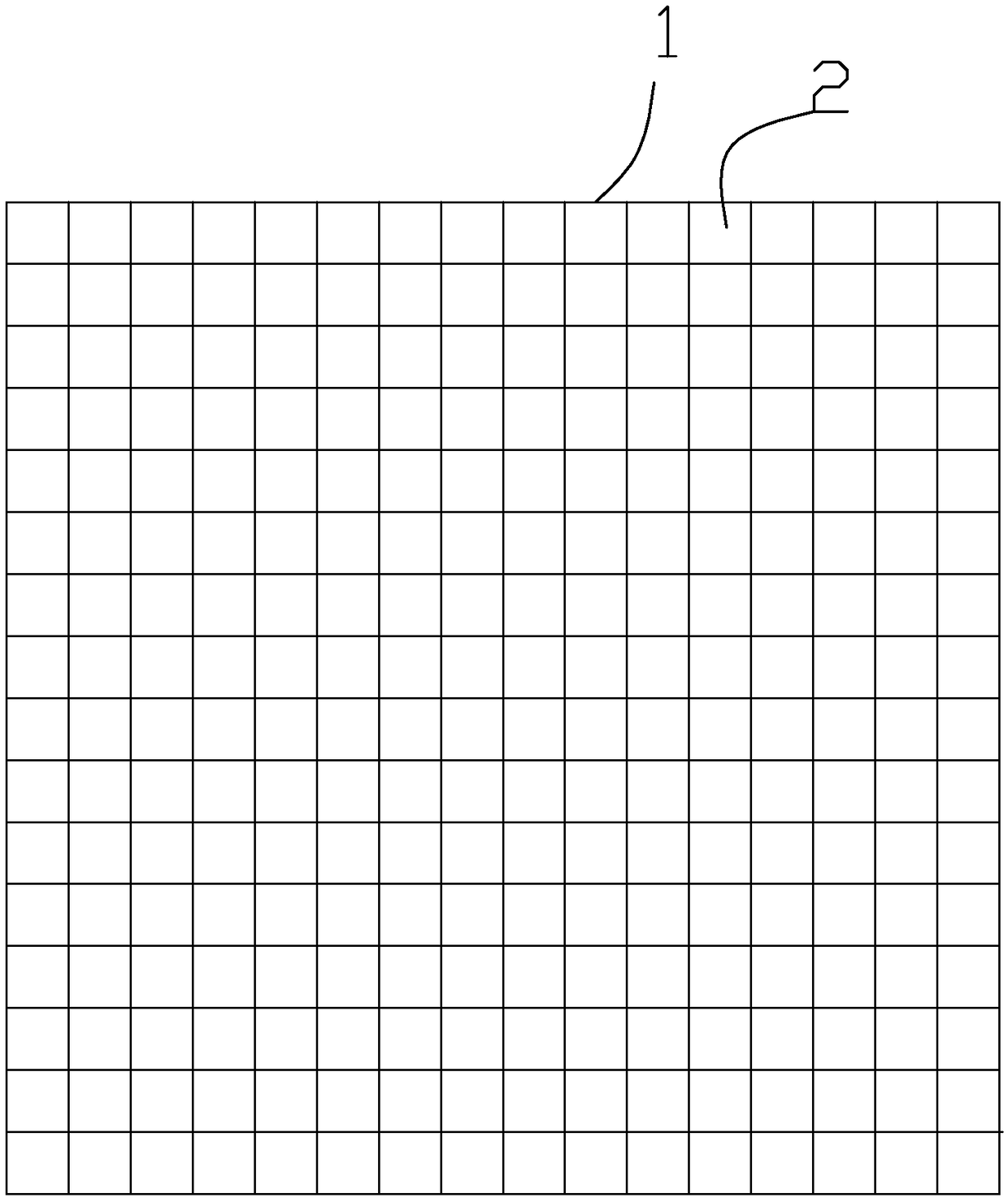

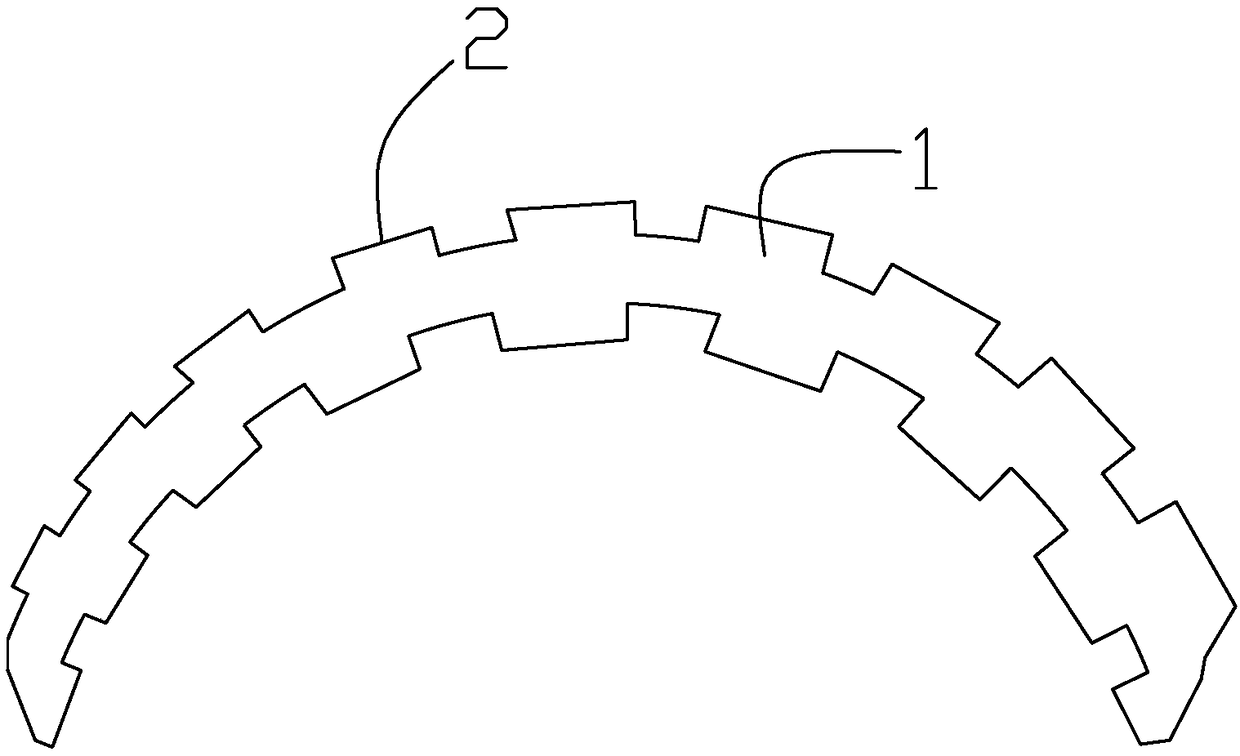

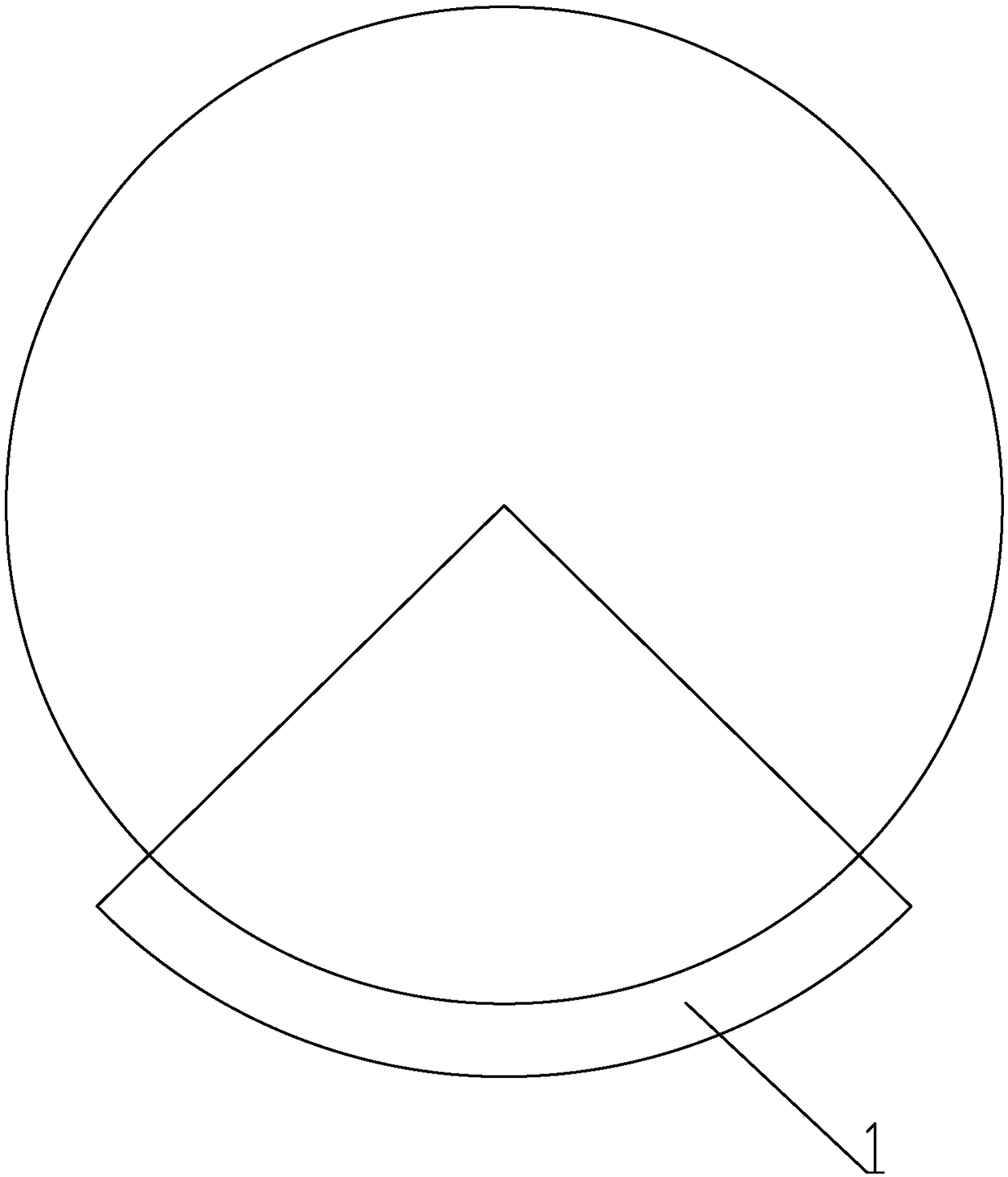

[0018] Figures 1 to 3 As shown, a tube shoe and its production method, the body 1 of the tube shoe and its production method is made of high-strength composite fibers; the upper surface and the lower surface of the body 1 are pressed to form a uniform concave-convex layer 2; The shape of the body 1 is set as a semicircle that is divided axially by an open cylinder.

[0019] The surface of the concave-convex layer 2 on both the upper surface and the lower surface of the body 1 of the pipe shoe and its manufacturing method is a smooth curved surface.

[0020] The high-strength composite fiber is high-strength high-modulus polyethylene fiber.

[0021] A method for making pipe shoes, the pipe shoes are uniformly melted and mixed at high temperature by raw materials, and finally pressed into molds;

[0022] The raw materials include 15% of synthetic resin, 83% of high-strength composite fiber and 2% of structural reinforcing agent in terms of mass percentage.

[0023] The inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com