Adhesion method for expanded bonding surface of metal silencing structure

A bonding method and sound-absorbing technology, applied in the field of aircraft maintenance, can solve the problems of stress fatigue of metal sound-absorbing structures, splashing of foreign objects such as sand and gravel, poor strength recovery effect, etc., and achieve simple bonding method, strong universality and stability. , the effect of convenient promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A bonding method for expanding the adhesive joint surface of a metal sound-absorbing structure, comprising the following steps:

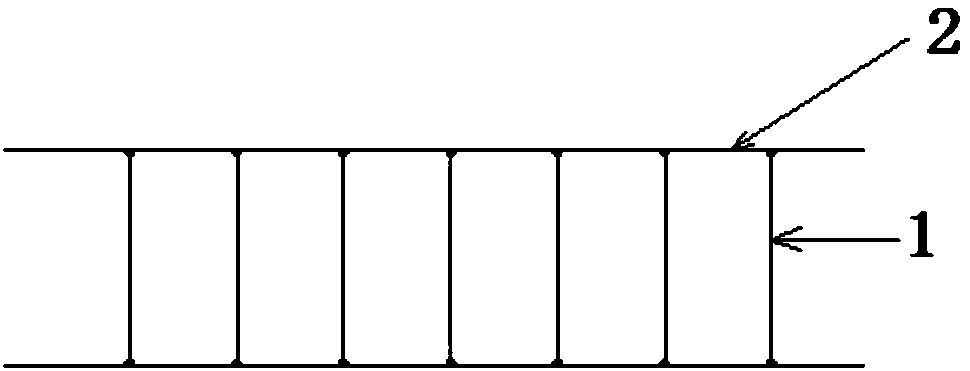

[0032] (1) Select a metal sound-absorbing structure, the metal sound-absorbing structure is composed of an aluminum metal honeycomb 1 and a perforated skin 2 arranged on the aluminum metal honeycomb 1, take out the perforated skin 2, and set a non-conductor on the top 1 of the aluminum metal honeycomb. Support film 3, such as image 3 shown;

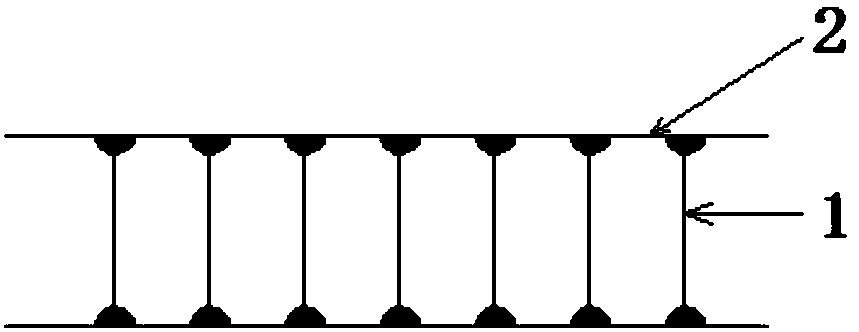

[0033] (2) On the unsupported adhesive film 3, a perforation 4 is set at the position facing the center of the honeycomb hole of the aluminum metal honeycomb 1, such as Figure 4 As shown, and use hot air to pretreat the unsupported adhesive film 3, so that the unsupported adhesive film is partially melted and shrunk to the cross-section of the aluminum metal honeycomb;

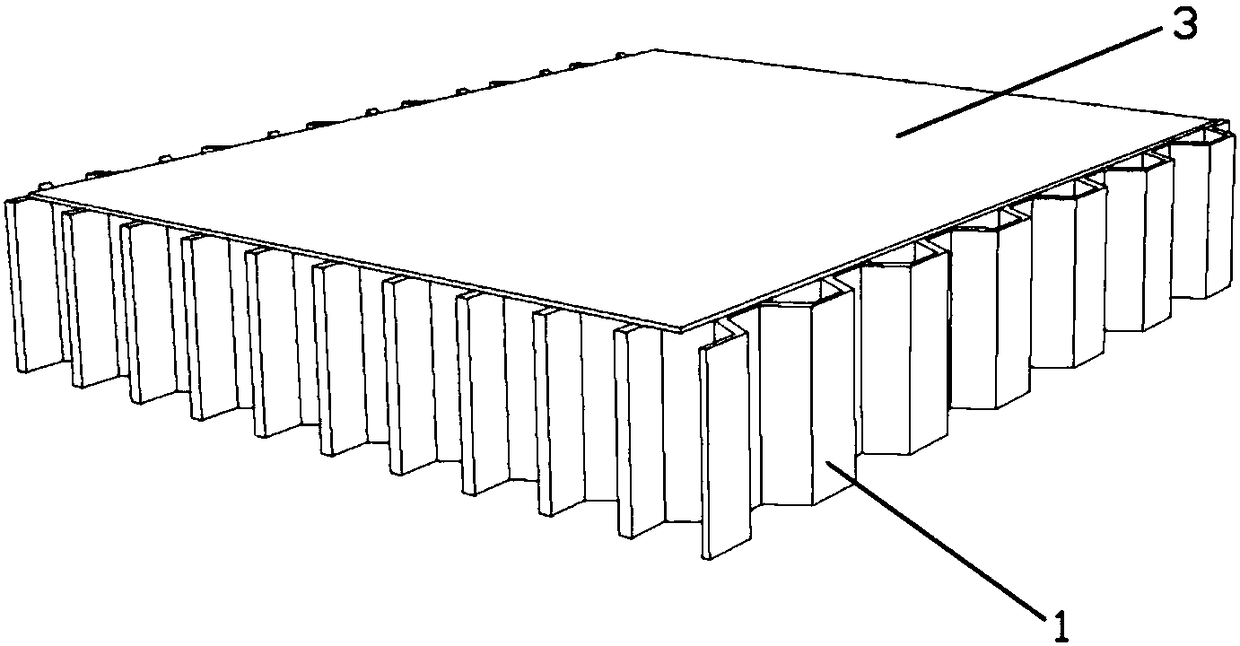

[0034] (3) On the unsupported adhesive film 3, the perforated skin 2 is laid, such as Figure 5 As shown, a metal sound-absorbing ...

Embodiment 2

[0042] A bonding method for expanding the adhesive joint surface of a metal sound-absorbing structure, comprising the following steps:

[0043] (1) Select a metal sound-absorbing structure, the metal sound-absorbing structure is composed of an aluminum metal honeycomb 1 and a perforated skin 2 arranged on the aluminum metal honeycomb 1, take out the perforated skin 2, and set a non-conductor on the top 1 of the aluminum metal honeycomb. Support film 3, such as image 3 shown;

[0044] (2) On the unsupported adhesive film 3, a perforation 4 is set at the position facing the center of the honeycomb hole of the aluminum metal honeycomb 1, such as Figure 4 As shown, and use hot air to pretreat the unsupported adhesive film 3, so that the unsupported adhesive film is partially melted and shrunk to the cross-section of the aluminum metal honeycomb;

[0045] (3) On the unsupported adhesive film 3, the perforated skin 2 is laid, such as Figure 5 As shown, a metal sound-absorbing ...

Embodiment 3

[0053] A bonding method for expanding the adhesive joint surface of a metal sound-absorbing structure, comprising the following steps:

[0054](1) Select a metal sound-absorbing structure, the metal sound-absorbing structure is composed of an aluminum metal honeycomb 1 and a perforated skin 2 arranged on the aluminum metal honeycomb 1, take out the perforated skin 2, and set a non-conductor on the top 1 of the aluminum metal honeycomb. Support film 3, such as image 3 shown;

[0055] (2) On the unsupported adhesive film 3, a perforation 4 is set at the position facing the center of the honeycomb hole of the aluminum metal honeycomb 1, such as Figure 4 As shown, and use hot air to pretreat the unsupported adhesive film 3, so that the unsupported adhesive film is partially melted and shrunk to the cross-section of the aluminum metal honeycomb;

[0056] (3) On the unsupported adhesive film 3, the perforated skin 2 is laid, such as Figure 5 As shown, a metal sound-absorbing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com