Ultraviolet radiation resistant montmorillonite intercalation modified polyurethane paint

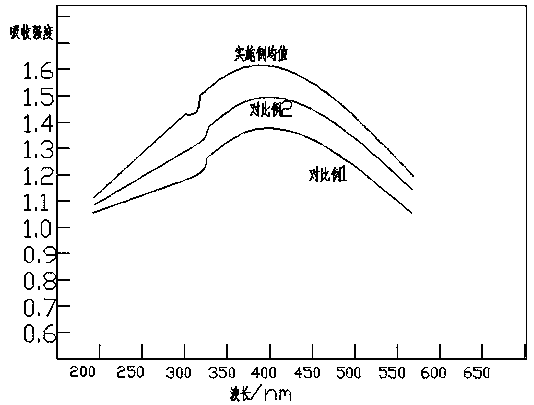

A polyurethane coating, UV-resistant technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult and uniform dispersion of organic matter, reduced coating film performance, large surface energy, etc. The effect of mechanical properties, strong scattering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

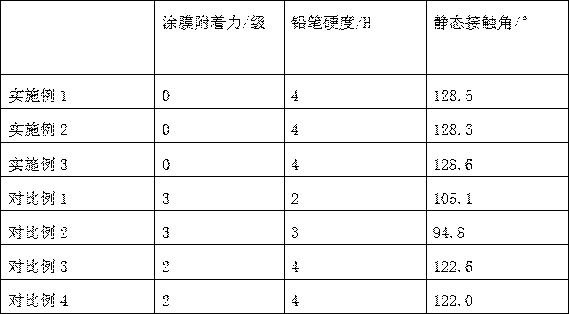

Examples

Embodiment 1

[0021] A montmorillonite intercalation modified polyurethane coating resistant to ultraviolet radiation is prepared by the following steps:

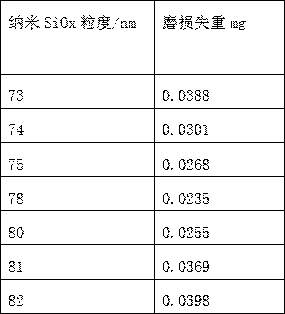

[0022] (1) Modified nano SiOx: Disperse nano SiOx uniformly in deionized water to prepare a 5.5% nano SiOx dispersion liquid, then add 0.3% alkanolamide by mass to the nano SiOx dispersion, and heat to At 80°C, add 0.12% dicumyl peroxide with nano-SiOx dispersion mass, stir at 1500r / min for 2 hours, then cool to room temperature naturally, filter with suction, dry to constant weight, and then use absolute ethanol Soak for 10 minutes, filter again, and dry to constant weight to get;

[0023] (2) Titanium dioxide / isocyanate compound: add 20g of titanium dioxide treated with coupling agent to 500mL of N,N-dimethylformamide, stir at 1800r / min for 30min, then heat to 110℃, keep for 15min , Then add 150g of isocyanate, continue stirring at 1800r / min for 2 hours, adjust the temperature to 10°C, keep holding for 30min, then remove N,N-dimethylformam...

Embodiment 2

[0033] A montmorillonite intercalation modified polyurethane coating resistant to ultraviolet radiation is prepared by the following steps:

[0034] (1) Modified nano SiOx: Disperse nano SiOx uniformly in deionized water to prepare a nano SiOx dispersion with a mass fraction of 6.5%, then add 0.5% alkanolamide by mass to the nano SiOx dispersion, and heat to At 90℃, add 0.15% dicumyl peroxide with nano-SiOx dispersion mass, stir at 1500r / min for 2 hours, then cool to room temperature naturally, filter with suction, dry to constant weight, and then use absolute ethanol Soak for 10 minutes, filter again, and dry to constant weight to get;

[0035] (2) Titanium dioxide / isocyanate compound: Add 30g of titanium dioxide treated with coupling agent to 500mL of N,N-dimethylformamide, stir at 1800r / min for 30min, then heat to 110℃, keep for 15min , Then add 180g of isocyanate, continue to stir at 1800r / min for 3 hours, adjust the temperature to 10°C, keep holding for 30min, then remove N,N...

Embodiment 3

[0045] A montmorillonite intercalation modified polyurethane coating resistant to ultraviolet radiation is prepared by the following steps:

[0046] (1) Modified nano SiOx: Disperse nano SiOx uniformly in deionized water to prepare a 6.0% nano SiOx dispersion liquid, then add 0.4% alkanolamide by mass to the nano SiOx dispersion, and heat to At 85°C, add 0.13% dicumyl peroxide of nano-SiOx dispersion mass, stir at 1500r / min for 2 hours, then cool to room temperature naturally, filter with suction, dry to constant weight, and then use absolute ethanol Soak for 10 minutes, filter again, and dry to constant weight to get;

[0047] (2) Titanium dioxide / isocyanate compound: add 25g of titanium dioxide treated with coupling agent to 500mL of N,N-dimethylformamide, stir at 1800r / min for 30min, then heat to 110℃, keep for 15min , Then add 160g of isocyanate, continue stirring at 1800r / min for 2.5 hours, adjust the temperature to 10°C, keep holding for 30min, then remove N,N-dimethylformam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com