A kind of nano-silver water-based polyurethane for self-sterilizing thin-walled materials and preparation method thereof

A water-based polyurethane and nano-silver technology, applied in the field of macromolecular polymers, can solve the problems of uneven dispersion of nano-silver particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

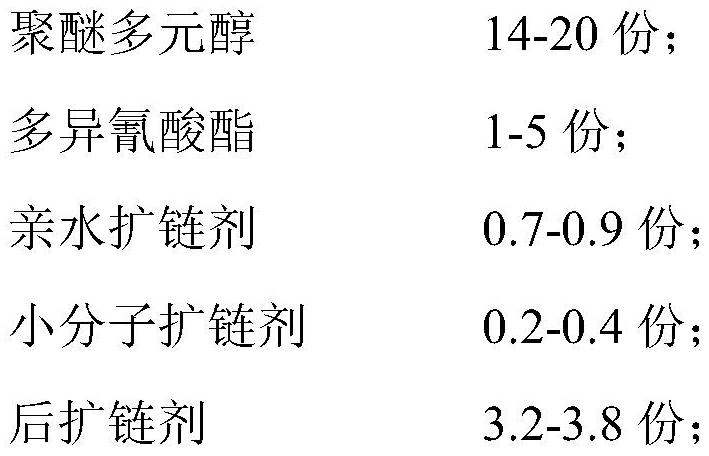

Method used

Image

Examples

Embodiment 1

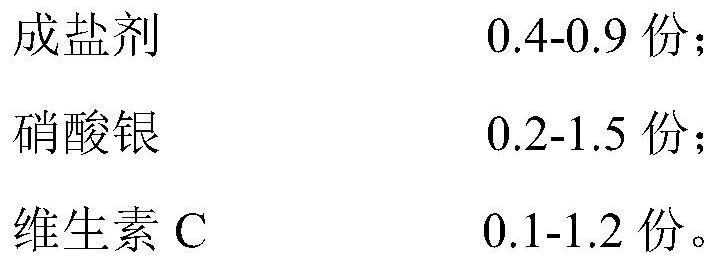

[0031] A preparation method of nano-silver water-based polyurethane, comprising the following steps:

[0032] (1) Preparation of solution: preparation of 50% silver nitrate aqueous solution; preparation of 16.6% IPDA aqueous solution; preparation of 9.1% vitamin aqueous solution.

[0033] (2) Preparation of prepolymer: Put 3.5 parts of PTMEG 2000 and 14 parts of PPG 3000 into the reaction kettle, stir and heat to 100-110°C, and vacuum dehydrate under the condition of -0.1MPa until the water content in the macromolecular glycol is 0.03 % or less, cool down to 40°C, put in 4.59 parts of IPDI, stir and heat up to 90°C, keep warm for 2 hours, cool down to 50°C, put in 0.79 parts of DMPA, 0.35 parts of CHDM and 4.67 parts of acetone, stir and heat up to 75°C React for 5 hours, then lower the temperature to 10°C, add 0.42 parts of triethylamine and 7.0 parts of acetone, stir for 5 minutes, add 0.66 parts of silver nitrate aqueous solution, and stir for 2 minutes to obtain a prepolym...

Embodiment 2

[0037] A preparation method of nano-silver water-based polyurethane, comprising the following steps:

[0038] (1) Preparation solution: preparation mass fraction is 33% silver nitrate aqueous solution; preparation mass fraction is 16.6% IPDA aqueous solution; preparation mass fraction is 9.1% vitamin aqueous solution.

[0039] (2) Preparation of prepolymer: Put 7.97 parts of PTMEG 3000 and 9.11 parts of PPG 3000 into the reaction kettle, stir and heat to 100-110°C, and vacuum dehydrate at -0.1MPa until the water content in the macromolecular glycol is 0.03 % or less, cool down to 40°C, put in 3.31 parts of IPDI and 1.07 parts of HDI, stir and heat up to 90°C, keep warm for 3 hours, cool down to 50°C, put in 0.87 parts of DMPA, 0.27 parts of BD and 4.55 parts of acetone, Stir and heat up to 80°C for 5 hours, then cool down to 10°C, add 0.46 parts of triethylamine and 11.39 parts of acetone, stir for 5 minutes, add 0.99 parts of silver nitrate aqueous solution, and stir for 2 mi...

Embodiment 3

[0043] A preparation method of nano-silver water-based polyurethane, comprising the following steps:

[0044] (1) Prepare solution: prepare a silver nitrate aqueous solution with a mass fraction of 33%; prepare an IPDA aqueous solution with a mass fraction of 16.6%; prepare a vitamin aqueous solution with a mass fraction of 2%.

[0045] (2) Preparation of prepolymer: Put 16.9 parts of PPG 3000 into the reaction kettle, stir and heat to 100-110°C, vacuum dehydrate under the condition of -0.1MPa until the water content in the macromolecular glycol is below 0.03%, and cool down to 40 ℃, put in 3.27 parts of IPDI and 1.65 parts of H12MDI, stir and heat up to 90°C, keep warm for 2 hours, cool down to 50°C, put in 0.86 parts of DMPA, 0.23 parts of MPD and 4.51 parts of acetone, stir and heat up to 75°C for reaction 5h, then lower the temperature to 10°C, add 0.45 parts of triethylamine and 11.26 parts of acetone, stir for 5 minutes, add 1.95 parts of silver nitrate aqueous solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com