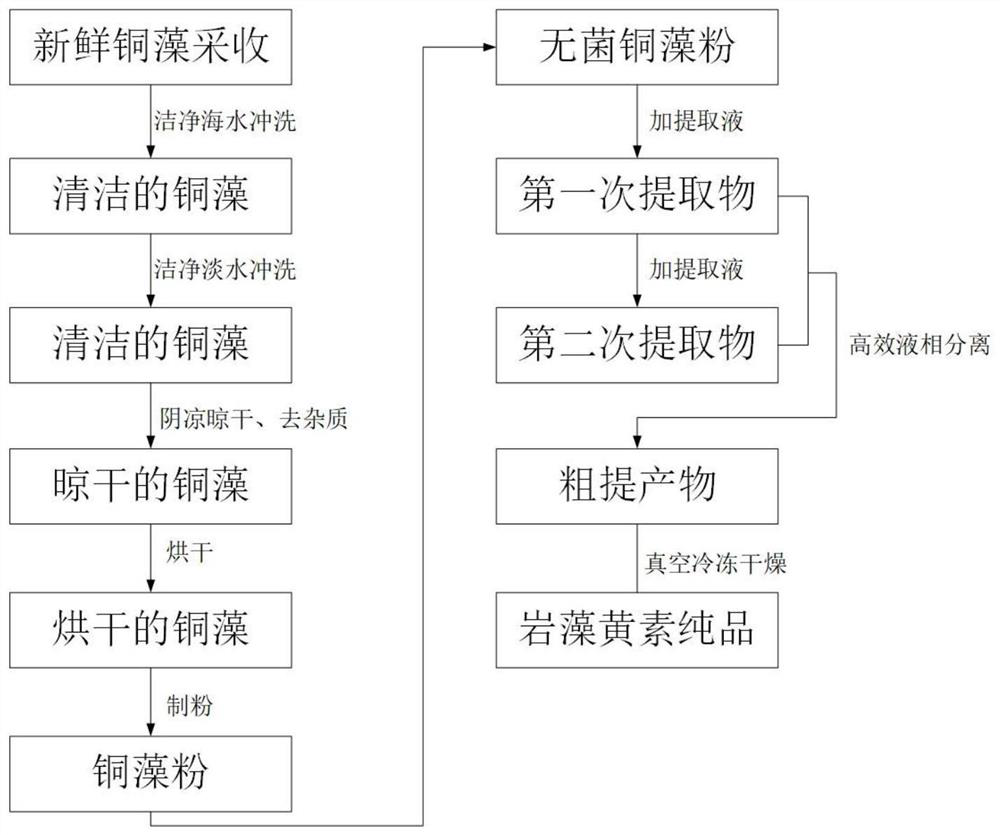

Preparation of copper algae algal powder and extraction method of fucoxanthin in the algal powder

A technology of fucoxanthin and extraction method, which is applied in the direction of organic chemistry, can solve the problems of high energy consumption and low purity, and achieve the effects of low energy consumption, low degradation rate and low harvesting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Using manual salvage, select the time period with weak ambient light (early morning or evening) to harvest fresh copper algae, and use shade cloth to cover the harvested algae. After harvesting, transfer the copper algae to a cool workshop with an ambient light of about 180Lux. Immediately use clean seawater to rinse and soak fresh copper algae. The seawater temperature is about 20°C and the salinity is 30‰ to fully remove the mud attached to the copper algae. Sand, small plankton, hook shrimp and other organisms. Quickly rinse copper algae for 1 minute with clean fresh water at a temperature of about 20°C. Spread the cleaned copper algae on a rack, remove the miscellaneous algae manually, drain the water and dry in the shade for 12 hours.

[0051] The fully drained semi-shade-dried copper algae was transferred to an electric heating oven, dried at 55° C. for 20 hours, turned every 1 hour, dried continuously for 12 hours, and fed with nitrogen at 20 L / min. The dried c...

Embodiment 2

[0055] Harvest fresh copper algae from the cultivation sea area, and use shade cloth to cover the harvested algae. Transfer the copper algae to a cool workshop with an ambient light of about 180Lux, and immediately rinse and soak fresh copper algae with clean sea water. The seawater temperature is about 20°C, and the salinity is 30‰. Plankton, hook shrimp and other organisms. Quickly rinse copper algae for 1 minute with clean fresh water at a temperature of about 20°C. Spread the cleaned copper algae on a rack, remove the algae manually, drain the water and dry in the shade for 12 hours.

[0056] The fully drained semi-shade-dried copper algae was transferred to an electric oven, dried at 60°C for 24 hours, turned every 1 hour, and nitrogen was introduced at 20L / min. The dried copper algae were frozen and ground into powder with liquid nitrogen, and passed through a 90-mesh sieve. Irradiation sterilization treatment of algal powder. Weigh 2g of algal powder, add 6mL of met...

Embodiment 3

[0060] Harvest fresh copper algae from the cultivation sea area, and use shade cloth to cover the harvested algae. Transfer the copper algae to a cool workshop with an ambient light of about 100Lux, and immediately rinse and soak fresh copper algae with clean sea water. The seawater temperature is about 20°C, and the salinity is 30‰. Plankton, hook shrimp and other organisms. Quickly rinse copper algae for 1 minute with clean fresh water at a temperature of about 20°C. Spread the cleaned copper algae on a rack, remove the algae manually, drain the water and dry in the shade for 12 hours.

[0061] The fully drained semi-shade-dried copper algae was transferred to an electric oven, dried at 60°C for 24 hours, turned every 1 hour, and nitrogen was introduced at 20L / min. The dried copper algae were frozen and ground into powder with liquid nitrogen, and passed through a 90-mesh sieve. Irradiation sterilization treatment of algal powder. Weigh 2g of algal powder, add 6mL of met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com