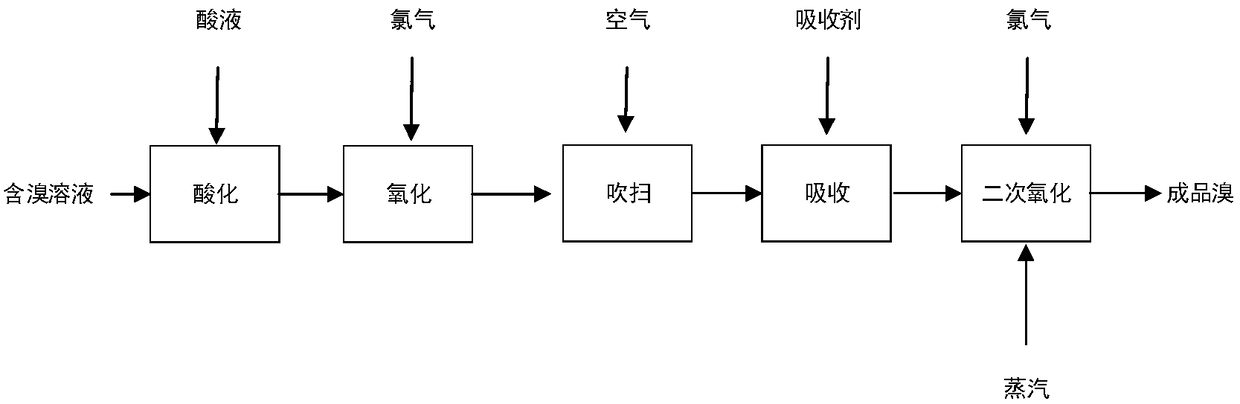

Method and device for increasing bromine stripping rate and extraction rate in air blowing-out process

A technology of air blowing and extraction rate, which is applied in the direction of bromine, bromine/hydrogen bromide, products, etc., can solve the problems of low stripping rate and overall extraction rate of bromine in the extraction process, so as to improve the recovery rate of purging and reduce the dissolution , Improve the effect of the overall extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

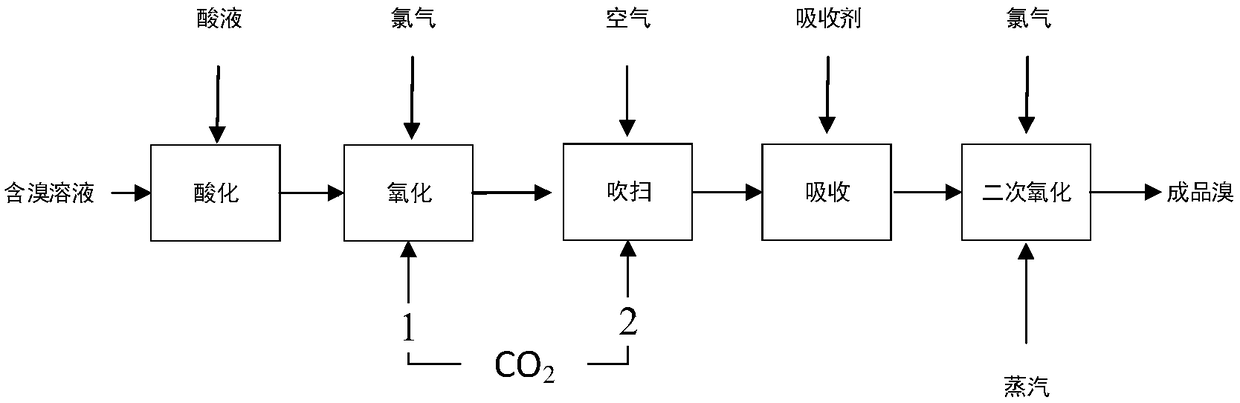

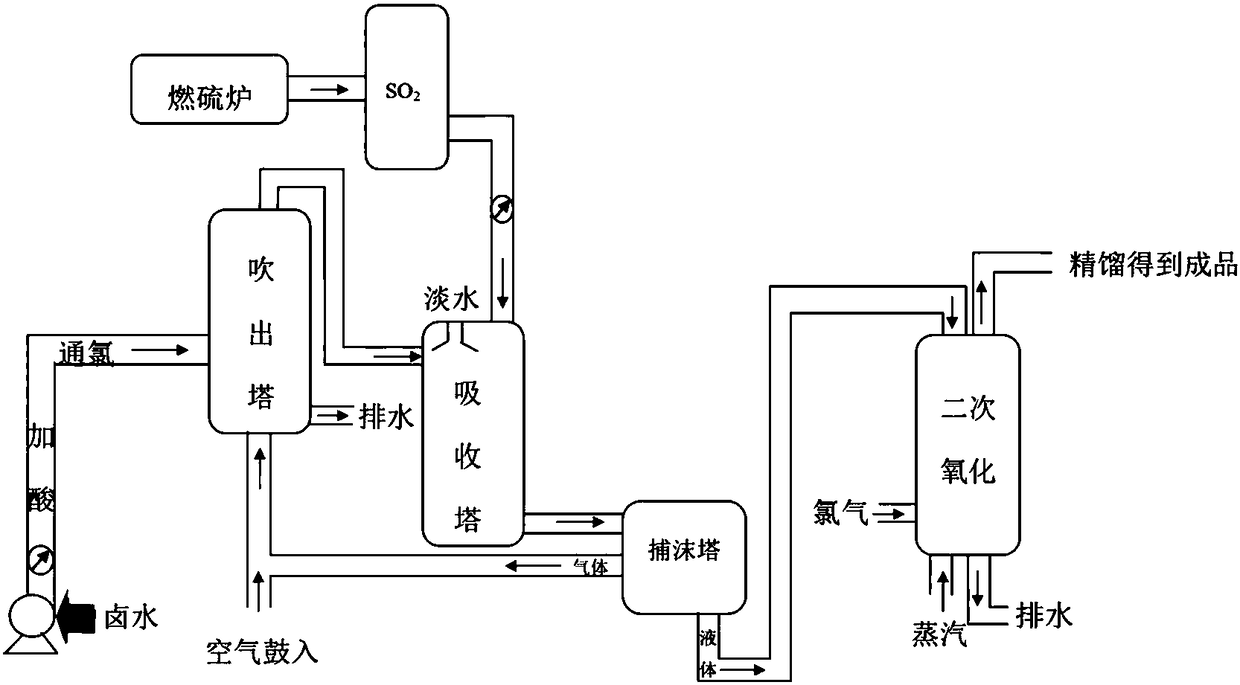

Method used

Image

Examples

Embodiment 1

[0043] This embodiment will show through the simulation experiment that CO passes through the brine before purging. 2 the effect that can be achieved.

[0044] 1. Solution configuration

[0045] Solution 1 (100mL): 10% NaCl, 0.5gNaBr (concentration at this time is 5000mg / L)

[0046] Solution 2: hypochlorous acid solution (containing 0.05% hypochlorous acid)

[0047] 2. Experimental steps

[0048] 2.1) Configure 100mL solution 1, adjust its pH value to 2 with concentrated hydrochloric acid and 1M NaOH solution, and simultaneously adjust the pH value of solution 2 to 2 with concentrated hydrochloric acid and 1M NaOH solution;

[0049] 2.2) Add dropwise solution 2 with the same pH value to solution 1, measure the Eh value of solution 1 with an Eh electrode, stop adding solution 2 when the Eh of the solution is at 950-1000mV, and obtain the completed oxidation solution for simulation . Simultaneously measure its NaBr content. In this step, using Eh and ClO - The correlation...

Embodiment 2

[0064] This embodiment is used to verify the improvement effect of the method of the present invention in the actual bromine air blowing production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com