Substandard ice cream stick pick-out machine

A technology for ice cream sticks and defective products, which is applied in packaging automatic control, packaging, packaging protection, etc., and can solve problems such as surface pollution of ice cream sticks and consumer harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

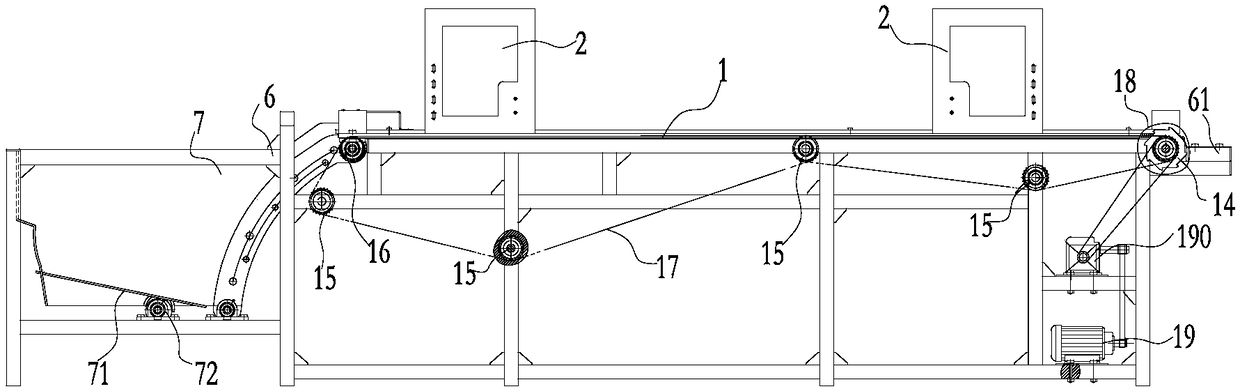

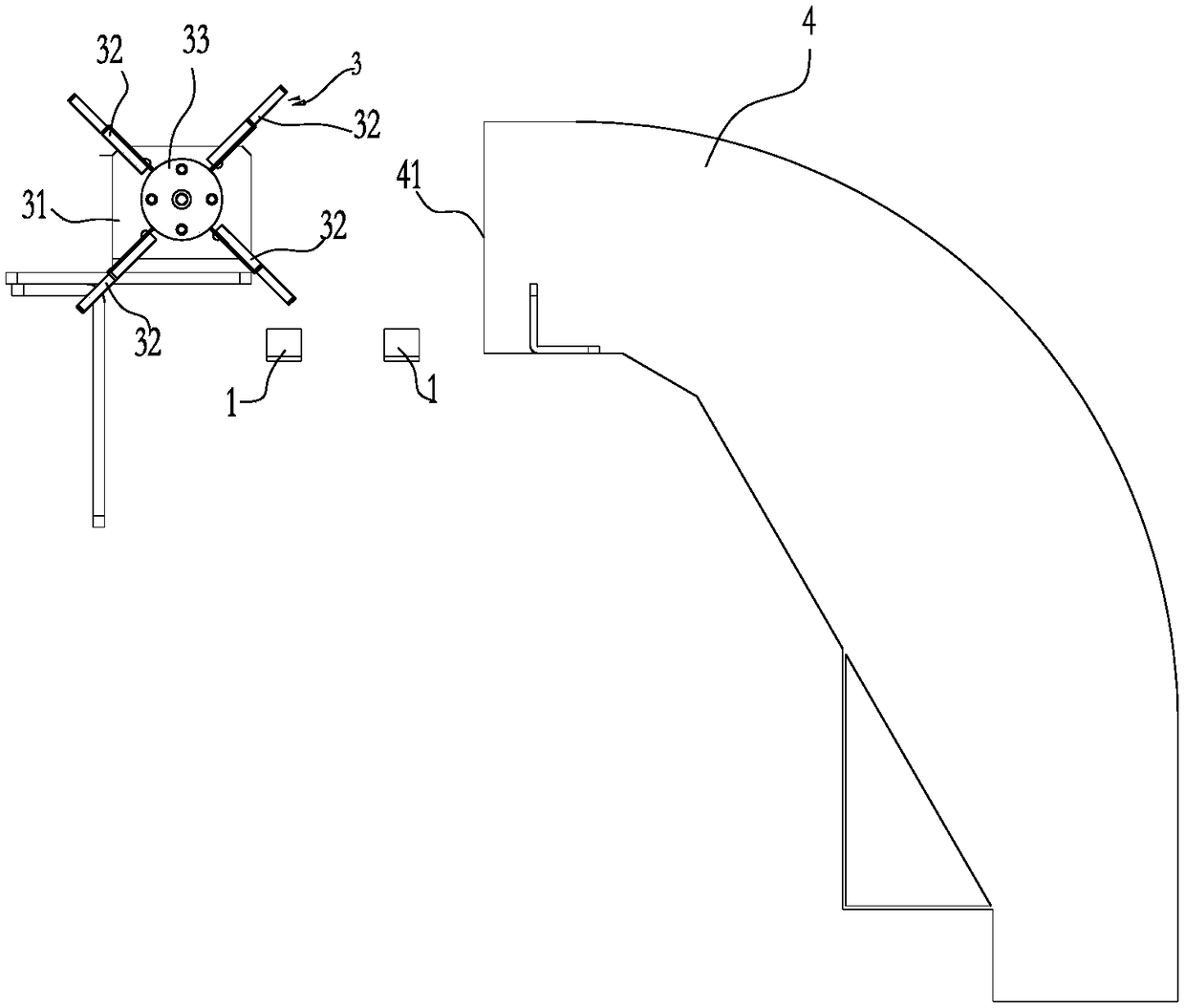

[0046] like Figure 1-Figure 5 As shown, a kind of ice cream stick defective product sorting machine of the present embodiment comprises the conveyor belt 1 that conveys ice cream sticks horizontally forward one by one, provides the loading bin 7 for the ice cream sticks for the conveyor belt 1, and drives the conveyor belt 1 to run. A chain transmission mechanism and at least one group of detection and removal mechanism; the detection and removal mechanism includes a visual inspection device 2 and a removal mechanism 3; the visual inspection device 2 is installed above the conveyor belt 1 and detects the Carry out image detection and analysis on the ice cream stick and judge whether the ice cream stick under inspection is a defective product, and control the operation of the material removal mechanism 3 according to the judgment result; the material removal mechanism 3 is installed on one side of the conveyor belt 1 and is located on the The front of the visual inspection dev...

Embodiment 2

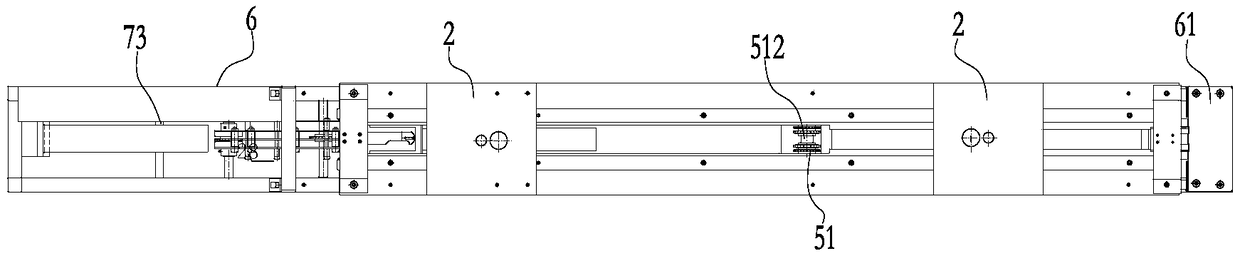

[0055] In addition to possessing the technical characteristics of embodiment 1, the ice cream stick defective product sorting machine of the present embodiment, as figure 1 and figure 2 As shown, the detection and rejecting mechanism is arranged in two groups and arranged front and back along the conveying direction of the conveyor belt 1; a turning mechanism 5 is installed under the conveyor belt 1, and the turning mechanism 5 is located in the detection mechanism of the two groups. Between the picking mechanism and the ice cream sticks on the conveyor belt passing through it are turned over sequentially. By arranging two sets of detecting and rejecting mechanisms, and setting an overturning mechanism between the two sets of detecting and rejecting mechanisms, both sides of the ice cream stick can be detected, so that the detection of the ice cream stick is more comprehensive and the detection accuracy is higher.

[0056] A specific implementation manner of this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com