Adjustable stable jaw crusher

A jaw crushing and adjustable technology, applied in the field of mining, can solve the problems of damage to the internal parts of the motor and crushing equipment, reducing work efficiency, increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

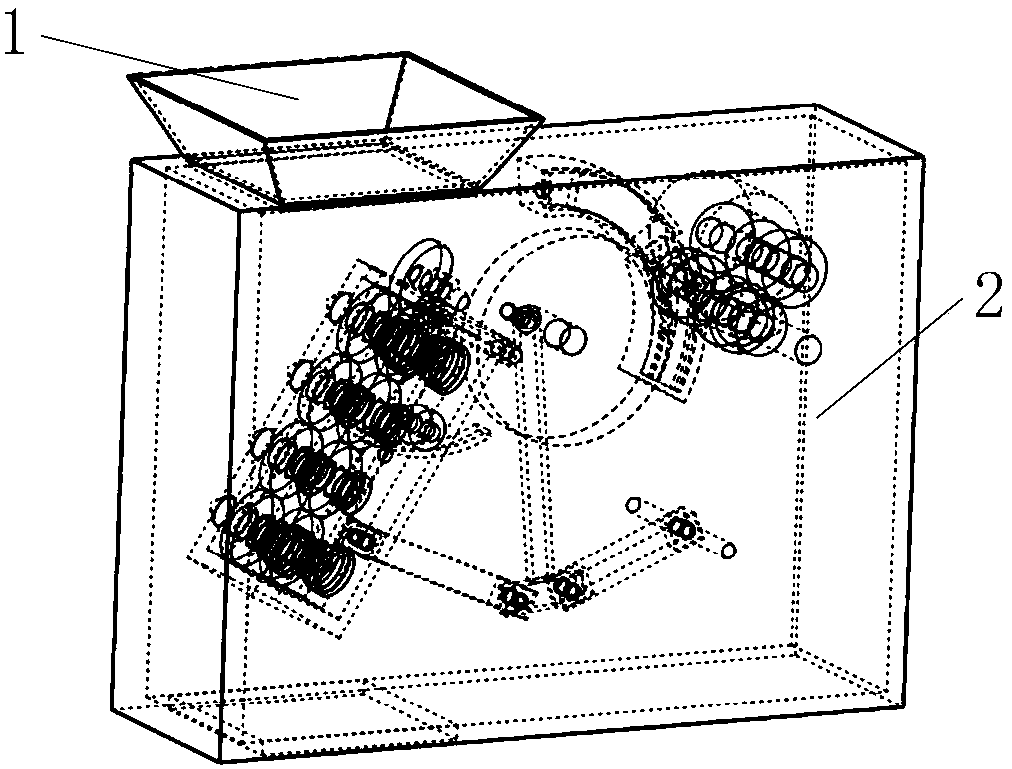

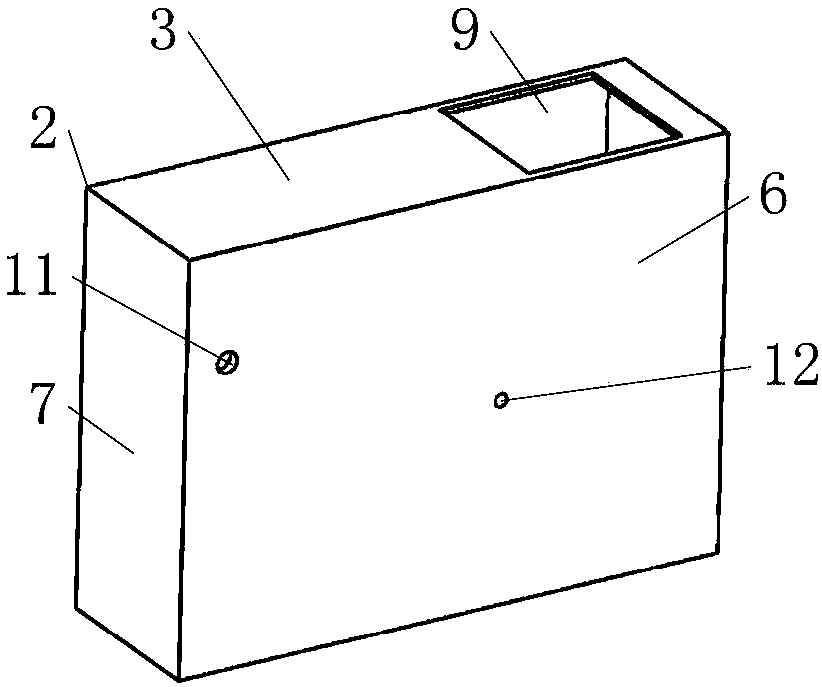

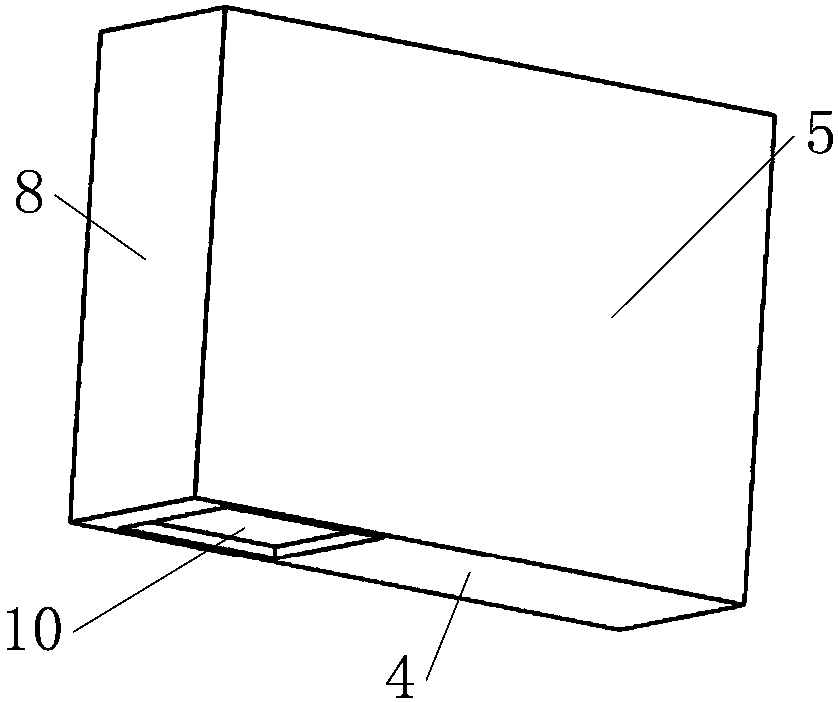

[0084] The specific embodiment: when the motor 25 starts to work, the motor 25 drives the first gear 27 to rotate; the first gear 27 drives the second gear 28, the third gear 29 and the fourth gear 30 to rotate; the second gear 28 drives the fifth gear 31 rotation; the fifth gear 31 drives the sixth gear 37 to rotate; the sixth gear 37 drives the movable jaw plate 65 to swing around the seventh shaft 18 through the first pull rod 38, the second pull rod 39 and the third pull rod 40; at the same time, the movable The jaw plate 65 drives the arc-shaped rack 73 to swing; the arc-shaped rack 73 drives the seventh gear 34 to rotate in one direction, and the seventh gear 34 drives the fifth shaft 14 to rotate in one direction; the fifth shaft 14 drives the sixth shaft 23 through a flexible shaft Unidirectional rotation, the sixth shaft 23 drives the eighth gear 33 to rotate in one direction; the eighth gear 33 drives the ninth gear 35 to rotate in one direction; the ninth gear 35 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com