Multifunctional threshing and redrying production line processing technology for leaf bases and leaf tips of tobacco leaves

A technology of threshing and redrying and processing technology, which is applied in tobacco, tobacco preparation, application, etc., can solve the problems of large investment and low equipment utilization rate, reduce the number of equipment and investment, meet processing requirements, and improve equipment utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

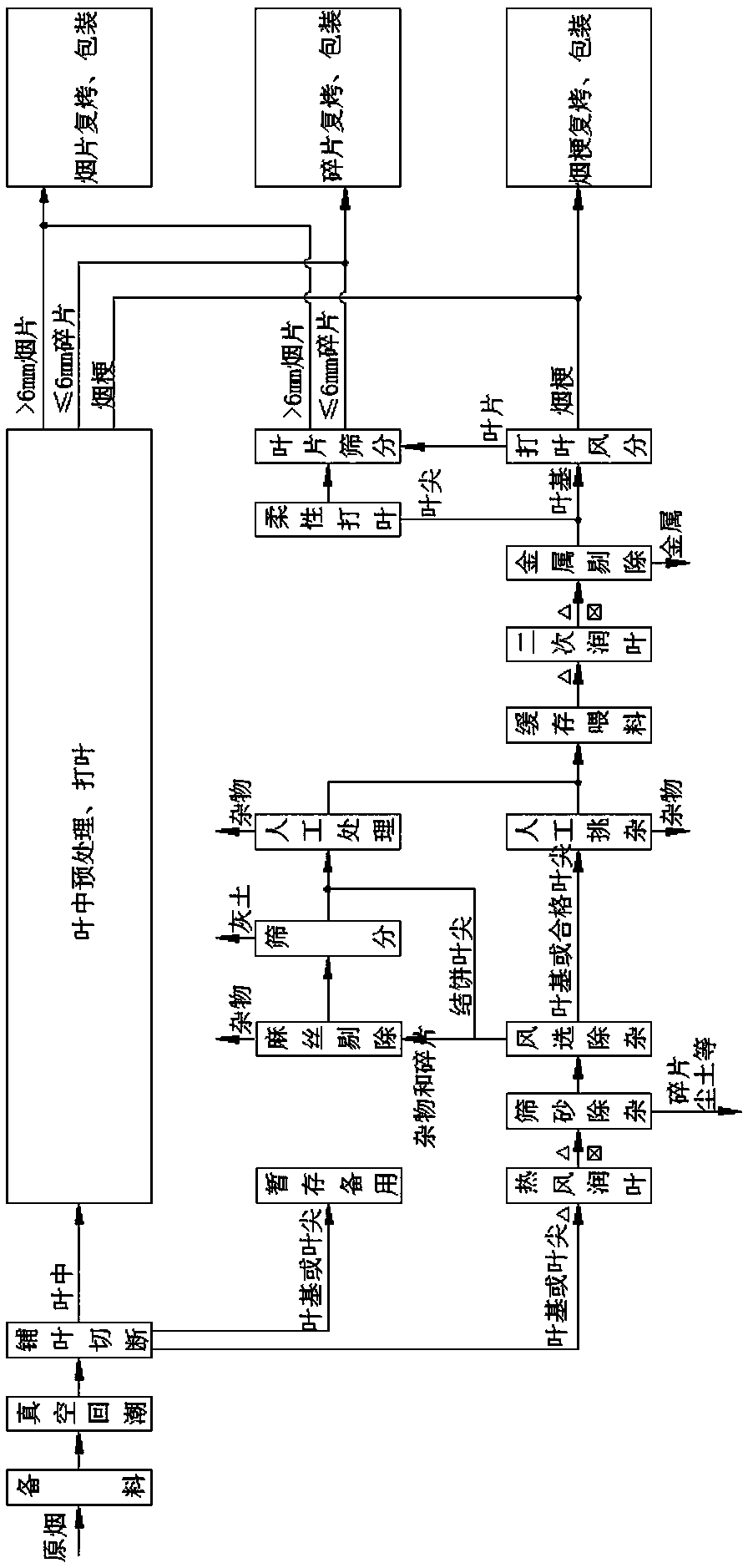

[0027] In order to describe in detail the technical content of the present invention, achieved purpose and effect, further description is made below in conjunction with process flow diagram and embodiment:

[0028] Such as figure 1 Shown: the processing technology of the multi-functional threshing and redrying production line of tobacco leaf base and tip according to the present invention, including the traditional mid-leaf pretreatment and threshing processing unit (1), leaf base or leaf tip processing unit (2) arranged in parallel , leaf base or blade tip temporary storage unit (3);

[0029] The leaf base or blade tip processing unit (2) sequentially includes primary hot air moistening, sand screening for impurity removal, air selection for impurity removal, artificial picking, buffer feeding, secondary leaf moistening, metal removal, and leaf base beating wind. Separation or leaf tip flexible threshing and leaf screening process; the leaves, fragments, and tobacco stems pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com