Preparation method of brown rice noodles

A technology for rice noodle and brown rice, which is applied in the field of preparing brown rice noodle, can solve the problems of poor eating taste, short storage time, accelerated brown rice product rancidity and the like, and achieves the effects of reducing activity and prolonging storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

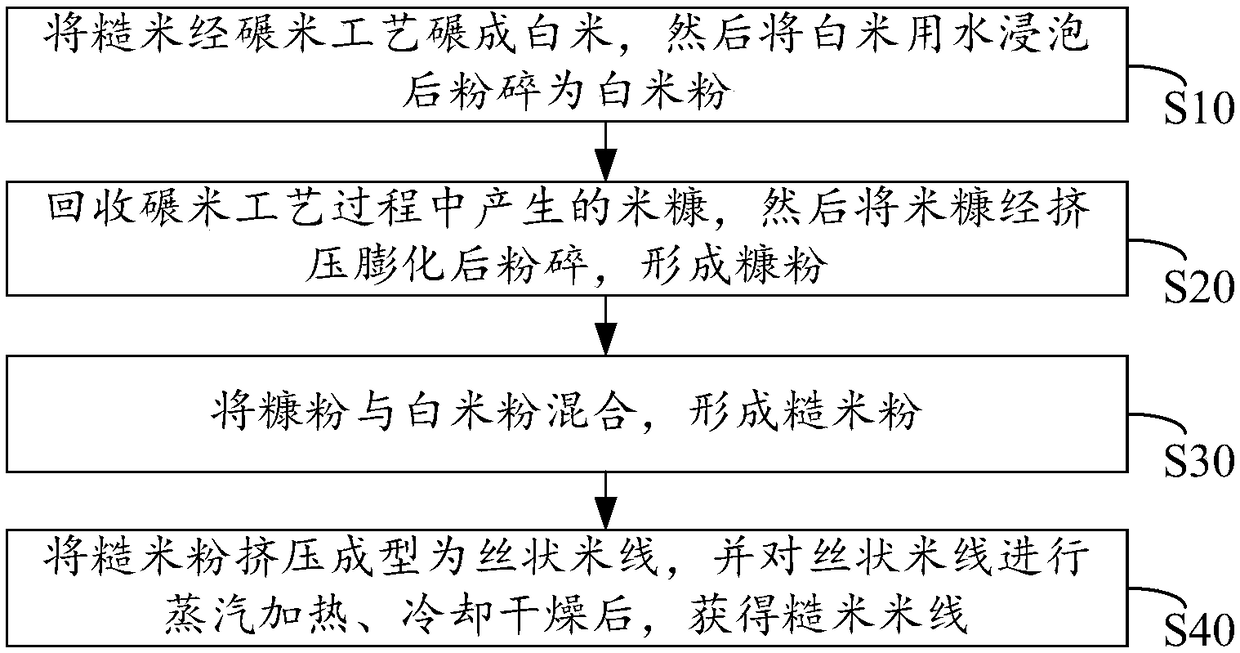

[0026] In order to reduce the content of insoluble dietary fiber in brown rice noodles, thereby improving the eating taste of brown rice noodles, the present invention proposes a method for preparing brown rice noodles, figure 1 It is an embodiment of the preparation method of the brown rice noodle provided by the present invention. see figure 1 , in the present embodiment, the preparation method of described brown rice noodle comprises the following steps:

[0027] Step S10, milling the brown rice into white rice through a rice milling process, then soaking the white rice in water and pulverizing it into white rice flour;

[0028] Wherein, the amylose content of the brown rice is not less than 20%. Rice starch includes amylopectin and amylose, wherein amylopectin reacts with hot water to form a paste, while amylose can be dissolved in water without forming a paste. Brown rice with an amylose content of not less than 20% is used as raw material , making brown rice noodles e...

Embodiment 1

[0042] (1) Preparation of white rice flour: use indica rice with an amylose content of 20% as the raw material of brown rice, grind it into white rice through a rice milling process, then soak the white rice in water for 8 hours, and then carry out wet milling. The obtained product is drained and dried and passed through an 80-mesh sieve to obtain white rice flour for subsequent use;

[0043] (2) Preparation of bran powder: reclaim the rice bran produced in the rice milling process in step (1), send the rice bran into an extrusion extruder for extrusion and puffing, and then pulverize and pass through an 80-mesh sieve to obtain the bran Powder, standby; Wherein, the parameter setting of extrusion extruder is: screw speed 200rpm, solid feed rate 18kg / h, liquid feed rate 6kg / h, described extrusion extruder is provided with the conveying direction of material successively. The first temperature zone, the second temperature zone, the third temperature zone, the fourth temperature ...

Embodiment 2

[0046] (1) Preparation of white rice flour: use indica rice with an amylose content of 25% as the raw material of brown rice, grind it into white rice through a rice milling process, then soak the white rice in water for 9 hours, and then carry out wet milling. The obtained product is drained and dried and passed through a 100-mesh sieve to obtain white rice flour for subsequent use;

[0047] (2) Preparation of bran powder: reclaim the rice bran produced in the rice milling process in step (1), send the rice bran into an extrusion extruder for extrusion and puffing, and then pulverize and pass through an 80-mesh sieve to obtain the bran Powder, standby; Wherein, the parameter setting of extrusion extruder is: screw speed 240rpm, solid feed rate 20kg / h, liquid feed rate 6.9kg / h, and described extrusion extruder is arranged successively along the conveying direction of material The first temperature zone, the second temperature zone, the third temperature zone, the fourth temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com