High-low-row planting operation machine

A working machine and seeding mechanism technology, applied in the field of agricultural machinery, can solve problems such as crop loss, complicated operation, blocking sunlight, etc., and achieve the effects of avoiding erosion damage, improving the growing environment, and avoiding moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

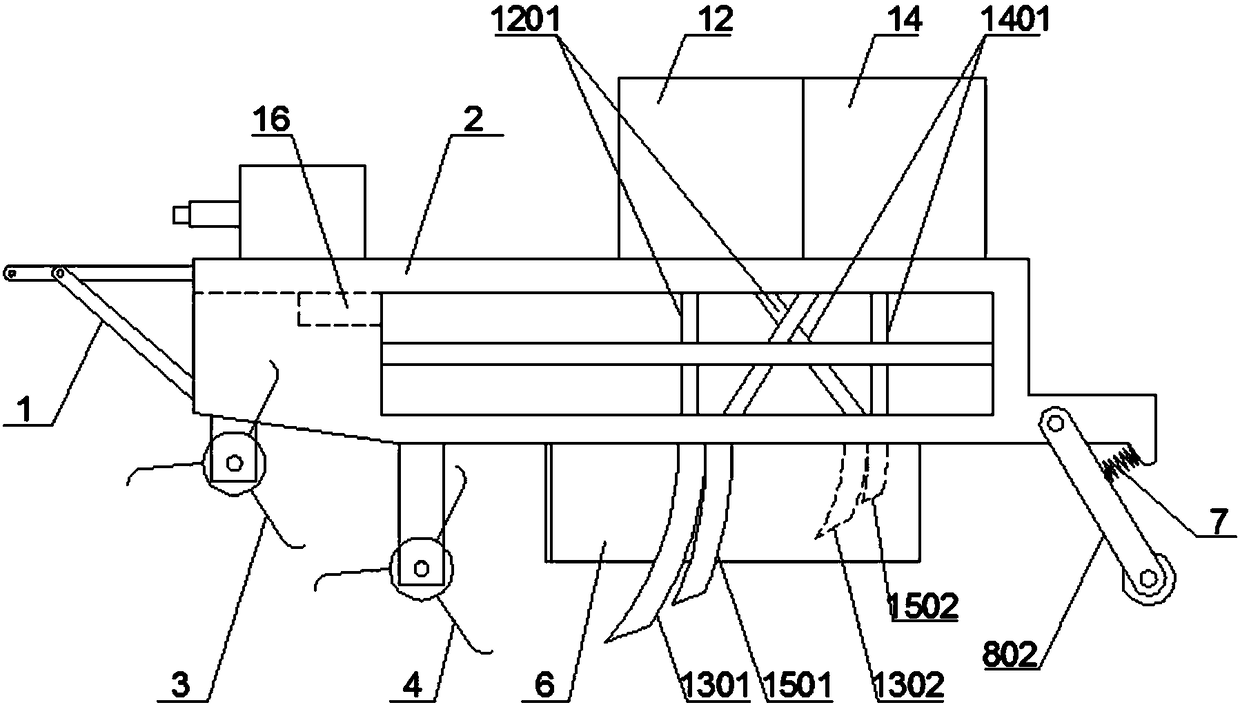

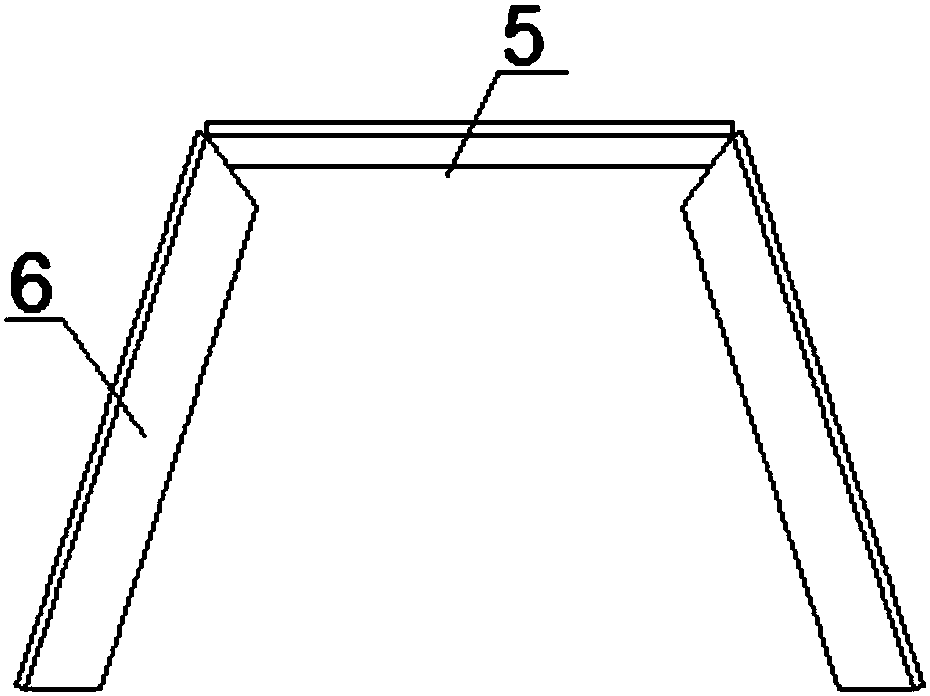

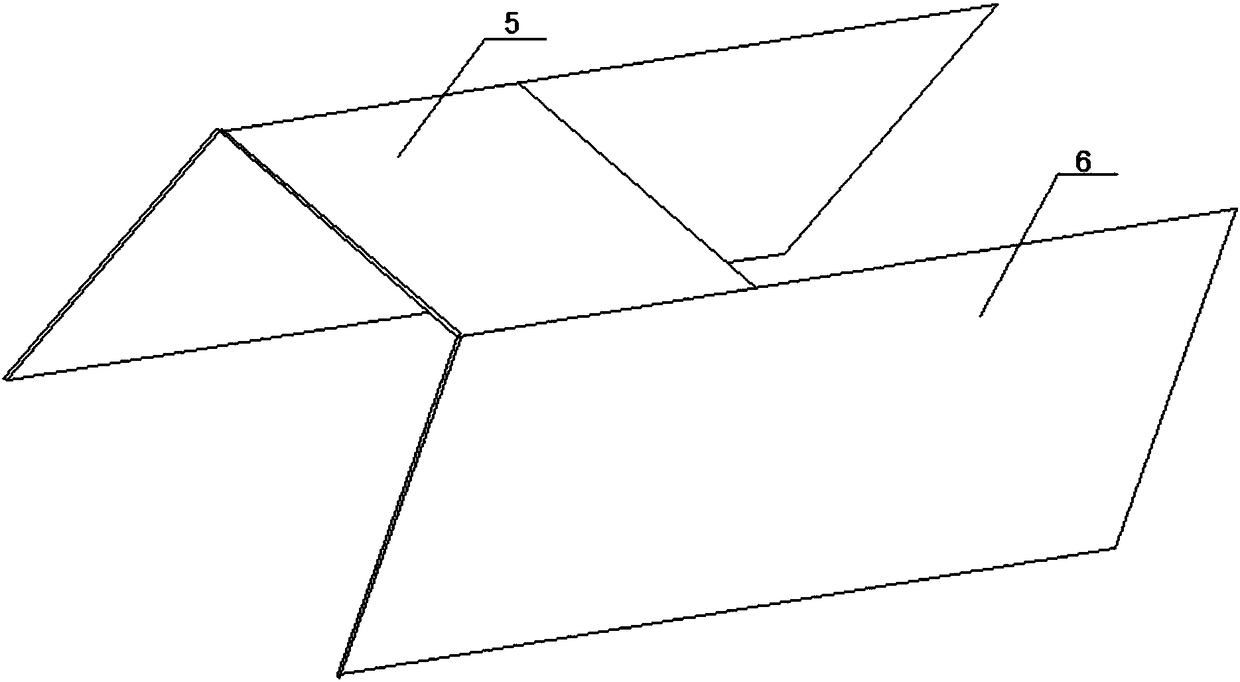

[0020] The present invention relates to a high and low row planting operation machine, comprising a frame 2 connected to the rear end of the tractor by means of a suspension frame 1, and a rotary tillage mechanism, a fertilization mechanism, a seeding mechanism and a suppression mechanism sequentially arranged on the frame 2. The rotary tillage mechanism includes a group of soil-raising rotary tillage wheels and a group of bottom rotary tillage wheels arranged at the bottom of the frame 2 in sequence. Both the soil-lift rotary tiller wheels and the bottom bottom rotary tiller wheels are arranged at intervals, and the soil-lift rotary tillage The operating depth of the wheel is 5-10cm, and the operating depth of the bottom rotary tillage wheel is 5-10cm lower than that of the soil rotary tillage wheel. The fertilizing mechanism and the seeding mechanism on the top; the soil-raising rotary tiller includes a rotating shaft and a soil-raising rotary tiller group 3 on the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com