Nitrogen-oxygen co-doped activated carbon aerogel electrode material, solid super-capacitor, and preparation method for nitrogen-oxygen co-doped activated carbon aerogel electrode material

A carbon aerogel and electrode material technology, applied in the field of electrochemistry, can solve the problems of low energy density and achieve high specific capacitance, reasonable pore size distribution, and small equivalent series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

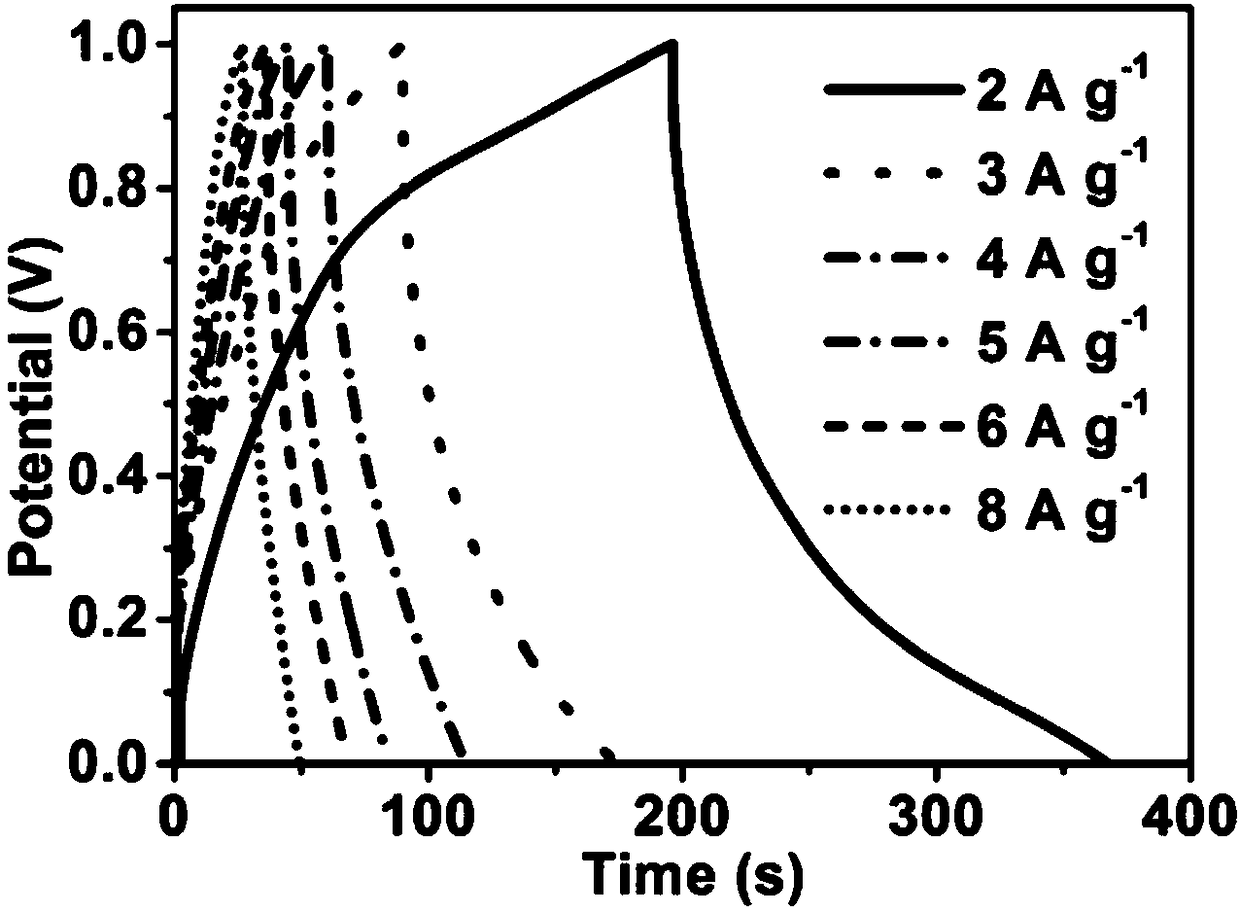

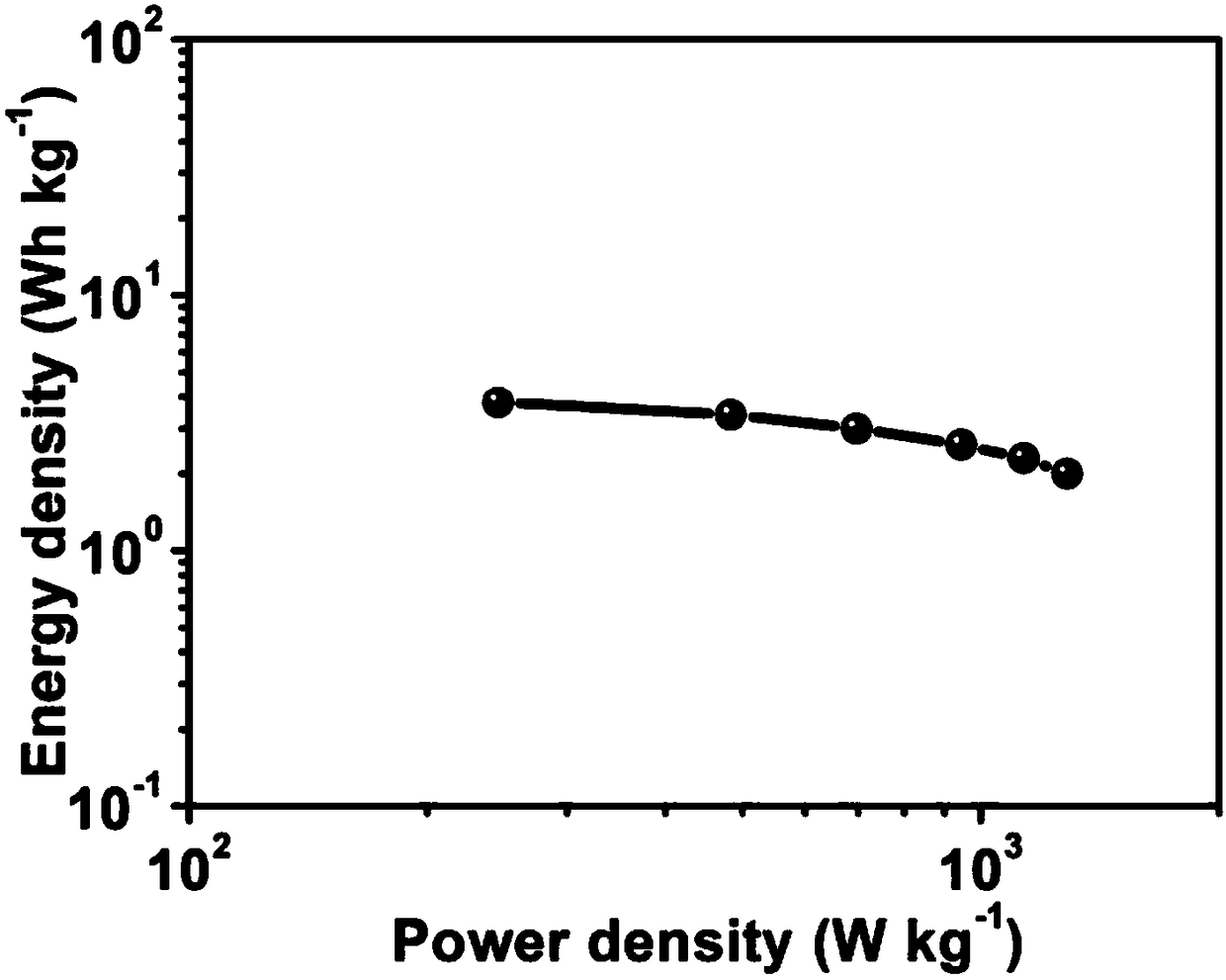

[0029] 0.3 g of sodium alginate was added to 15 mL of deionized water, and stirred at room temperature for 24 h to obtain a transparent solution. Then take 0.5g of aniline monomer and add it to the above-mentioned ice-water bath for magnetic stirring, then take 0.57g of initiator solution to initiate aniline polymerization, and put sodium alginate-polyaniline airgel, that is, nitrogen and oxygen co-doped activated carbon aerogel, through freezing Drying technology Drying for 48h. The obtained samples were pre-carbonized at 450°C for 2 hours, and then kept at 600°C for 2 hours; mixed with an activator, the dried samples were directly heated from room temperature to 600°C for 2 hours.

[0030] The sodium alginate-based nitrogen-oxygen co-doped activated carbon airgel electrode material activated by carbonization at 600°C, the conductive agent and the binder were mixed in a ratio of 90:5:10 to make a slurry, and then coated on the corresponding On a current collector of a certai...

Embodiment 2

[0034] 0.3 g of sodium alginate was added to 15 mL of deionized water, and stirred at room temperature for 24 h to obtain a transparent solution. Then take 0.5g of aniline monomer and add it to the above-mentioned ice-water bath for magnetic stirring, then take 0.57g of initiator solution to initiate the polymerization of aniline, and dry the sodium alginate-polyaniline airgel by freeze-drying technology for 48 hours. The obtained samples were pre-carbonized at 450°C for 2 hours, and then kept at 700°C for 2 hours; mixed with an activator, the dried samples were directly heated from room temperature to 700°C for 2 hours.

[0035] The sodium alginate-based nitrogen-oxygen co-doped activated carbon airgel electrode material activated by carbonization at 700°C, the conductive agent and the binder were mixed in a ratio of 80:15:5 to make a slurry, and then coated on the corresponding On a current collector of a certain size, dry it at 80°C to obtain a supercapacitor electrode shee...

Embodiment 3

[0039] 0.3 g of sodium alginate was added to 15 mL of deionized water, and stirred at room temperature for 24 h to obtain a transparent solution. Then take 0.5g of aniline monomer and add it to the above-mentioned ice-water bath for magnetic stirring, then take 0.57g of initiator solution to initiate the polymerization of aniline, and dry the sodium alginate-polyaniline airgel by freeze-drying technology for 48 hours. The obtained samples were pre-carbonized at 450°C for 2 hours, and then kept at 800°C for 2 hours; mixed with an activator, the dried samples were directly heated from room temperature to 800°C for 2 hours.

[0040] The sodium alginate-based nitrogen-oxygen co-doped activated carbon airgel electrode material activated by carbonization at 800°C, the conductive agent and the binder were mixed at a ratio of 85:8:8 to make a slurry, and then coated on the corresponding On a current collector of a certain size, dry it at 80°C to obtain a supercapacitor electrode sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com