Method for preparing cuprous thiocyanate by using ammonia-process coking desulfurization waste liquid

A technology of coking desulfurization waste liquid and cuprous thiocyanate, which is applied in the direction of thiocyanate and ammonium sulfate, to achieve the effect of improving economic benefits and solving poor sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The coking desulfurization waste liquid used in this example is the desulfurization waste liquid produced by removing hydrogen sulfide from the coking gas of the coking plant by using the HPF method. Take 500 mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are ammonium thiocyanate, thiosulfuric acid Ammonium, ammonium sulfate, suspended sulfur, PDS, free ammonia.

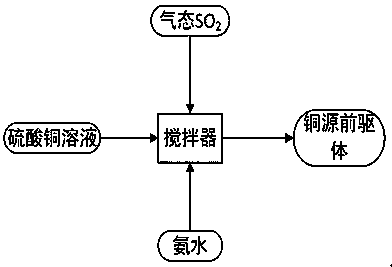

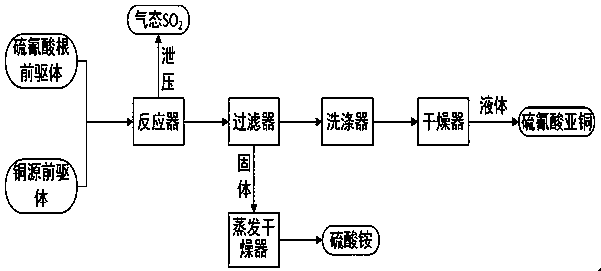

[0032] In the first step, 195.3 mL of 28 wt.% ammonia water was added to 500 mL of saturated copper sulfate solution, stirred to make it fully react, and 8.75 L of 99.99% SO 2 Gas (Cu 2+ : NH 4 + : SO 2 =2:4:1, the unit is the molar ratio), to obtain the copper source precursor, to collect and purify the tail gas;

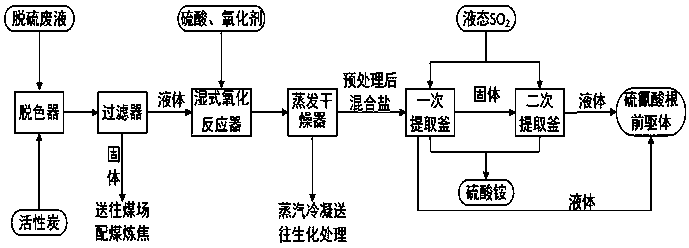

[0033] The second step, the preparation of thiocyanate precursor

[0034] Ⅰ. Add 5 g of activated carbon to 500 mL of ammonia desulfurization waste liquid, stir at 80 °C for 180 min, and then filter to obtain decolorized desulfurization waste liqu...

Embodiment 2

[0041] The coking desulfurization waste liquid used in this example is the desulfurization waste liquid produced by removing hydrogen sulfide from the coking gas of the coking plant by using the HPF method. Take 500 mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are ammonium thiocyanate, thiosulfuric acid Ammonium, suspended sulfur, PDS, free ammonia.

[0042] In the first step, add 218.75 mL of 5 wt.% ammonia water to 500 mL of 5% copper sulfate solution, stir to make it fully react, and pass 3.85 L of 50% SO 2 Gas (Cu 2+ : NH 4 + : SO 2 =2:4:1.1, the unit is the molar ratio) to obtain the copper source precursor, and the tail gas is collected and purified;

[0043] The second step, the preparation of thiocyanate precursor

[0044] Ⅰ. Add 25 g of activated carbon to 500 mL of ammonia desulfurization waste liquid, stir for 120 min at a temperature of 20 °C, and then filter to obtain decolorized desulfurization waste liquid....

Embodiment 3

[0051] The coking desulfurization waste liquid used in this example is the desulfurization waste liquid produced by removing hydrogen sulfide from the coking gas of the coking plant by using the HPF method. Take 500 mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are ammonium thiocyanate, thiosulfuric acid Ammonium, suspended sulfur, PDS, free ammonia.

[0052] In the first step, add 218.75 mL of 20wt.% ammonia water to 500 mL of 15% copper sulfate solution, stir to make it fully react, and pass 9.8 L of 75% SO 2 Gas (Cu 2+ : NH 4 + : SO 2 =2:4:1.05, the unit is the molar ratio), to obtain the copper source precursor, the tail gas is collected and purified;

[0053] The second step, the preparation of thiocyanate precursor

[0054] Ⅰ. Add 15 g of activated carbon to 500 mL of ammonia desulfurization waste liquid, stir for 90 min at a temperature of 50 °C, and then filter to obtain decolorized desulfurization waste liquid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com