Board card radiator heat transfer cement pressing device

A heat-conducting cement and heat sink technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve problems such as heat sink deflection, loud noise, heat sink, heat-conducting pad and heat-dissipating elements cannot be in close contact, etc., to ensure pressing Quality, simplified heat dissipation structure, and avoid board deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

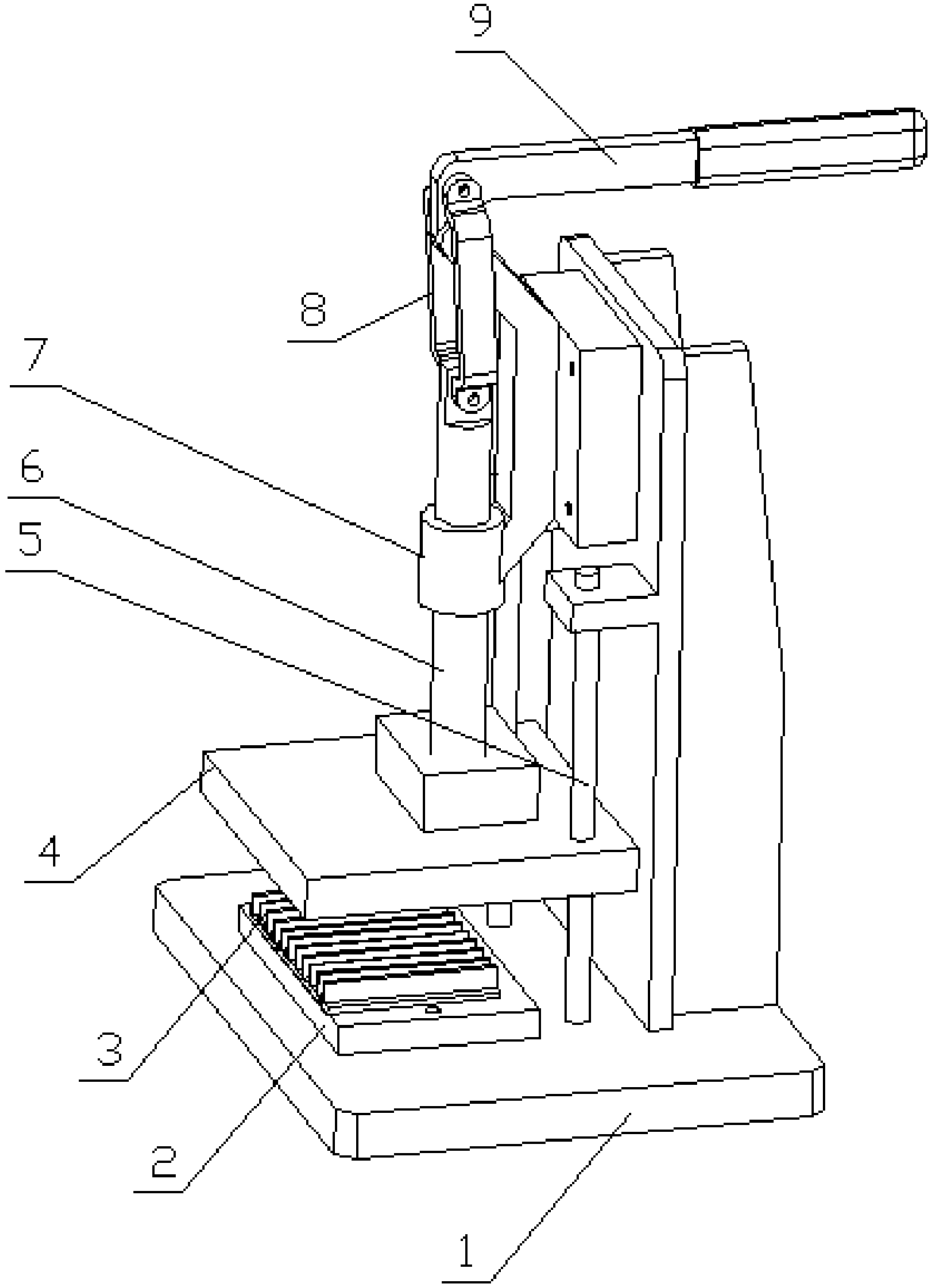

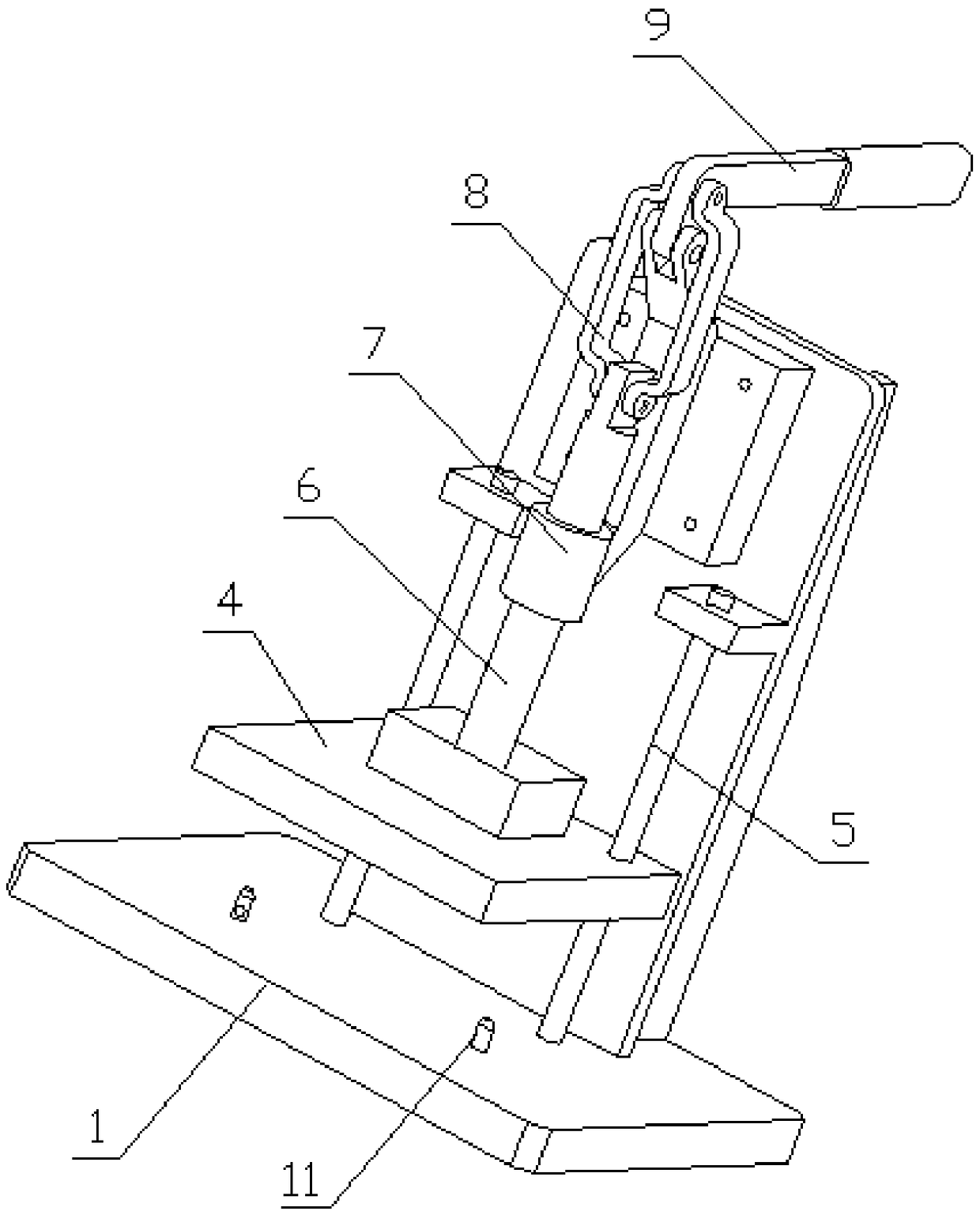

[0019] Such as figure 1 with figure 2 As shown, a heat-conducting cement pressing tool for radiators includes a frame 1, on which a cement mold 2 is placed horizontally, and a radiator positioning structure for positioning the radiator 3 is provided on the upper plane of the cement mold , the frame 1 is provided with a briquetting block 4 for pressing the radiator 3 on the mastic mould, and a briquetting lifting drive device for driving the briquetting up and down above the mastic mold.

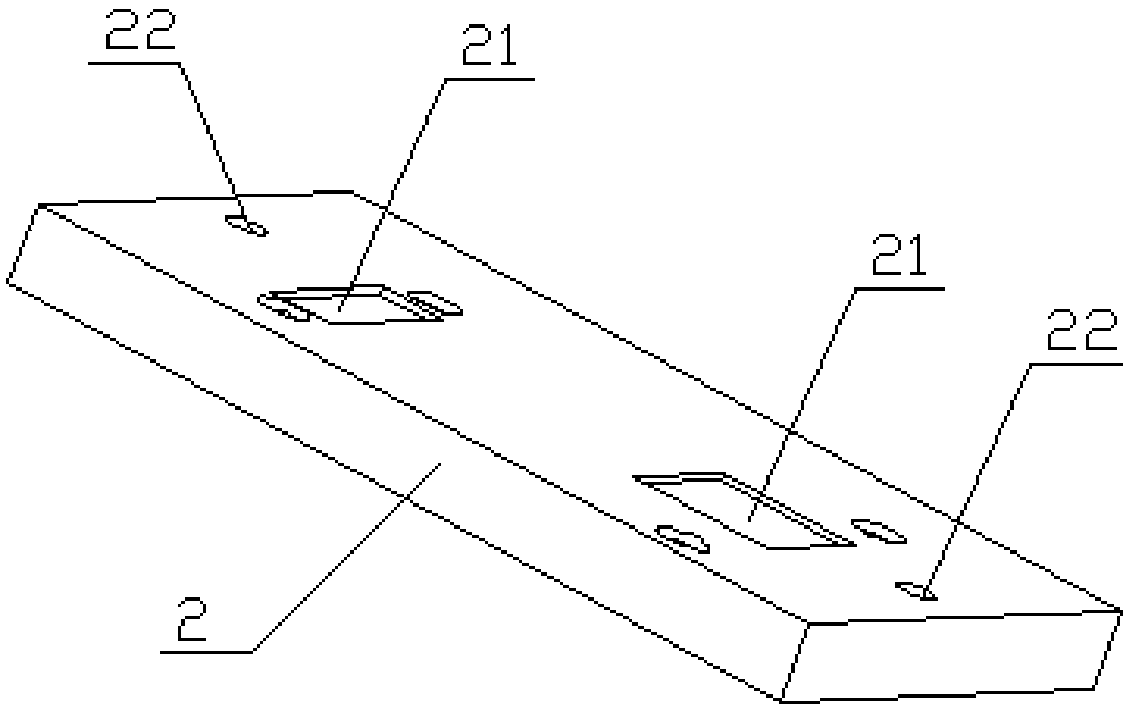

[0020] Such as image 3 As shown, the upper plane of the cement mold is provided with a cement cavity 21 for placing the cement. The size and height of the cement cavity corresponding to the electronic components on the board are designed to be pressed into the corresponding heat-conducting cement block. Therefore, the position, quantity, depth and area of the cement cavity 21 can be adjusted as required to meet the requirements of the heat-conducting cement block. Depending on the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com