DC power supply micro-current starting circuit

A start-up circuit and DC power supply technology, applied in the direction of electrical components, output power conversion devices, etc., can solve the problems of occupying PCB boards, large losses, increased costs, etc., achieve simple structure, use fewer components, and avoid overheating and burning bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

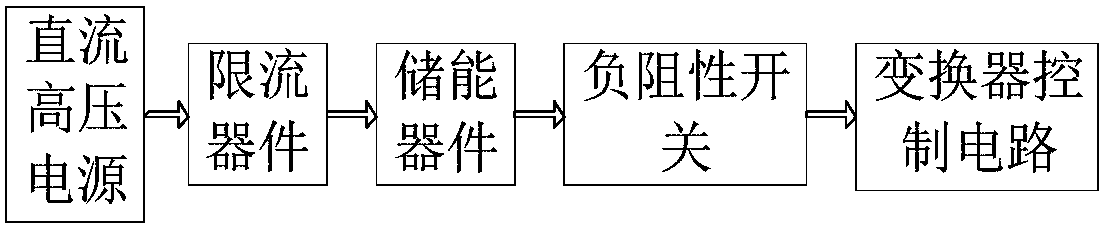

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

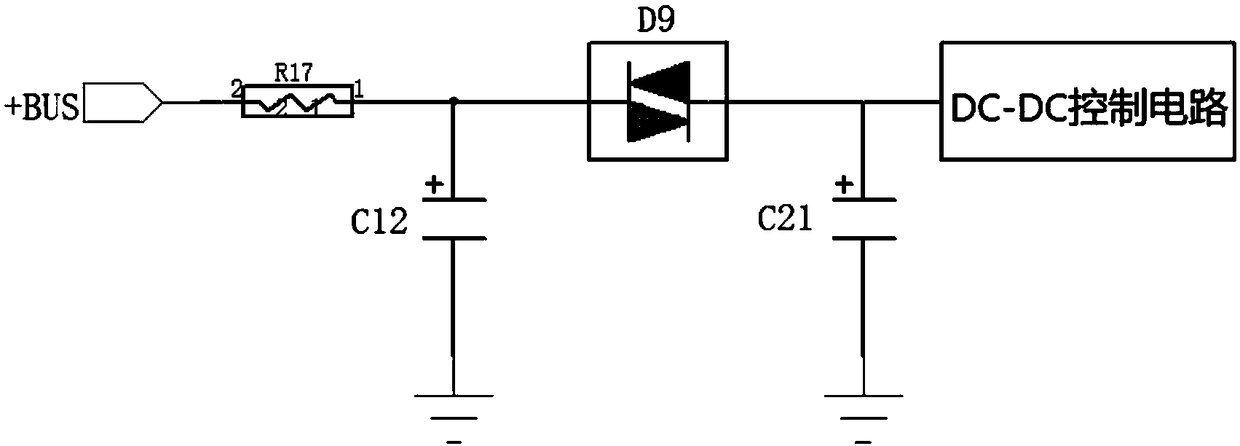

[0040] Such as figure 2 As shown, the DC power supply micro-current starting circuit provided by the present invention further includes a capacitor C21; the current limiting circuit includes a resistor R17, the tank circuit includes a capacitor C12, and the negative resistive switch includes a bidirectional trigger diode D9. One end of the resistor R17 forms a high-voltage DC power supply +BUS connection, the other end of the resistor R17 is connected to one end of the capacitor C12 and one end of the bidirectional trigger diode D9; the other end of the capacitor C12 is grounded; the other end of the bidirectional trigger diode D9 is connected to the capacitor One end of C21 forms a DC-DC control circuit connection end; the other end of capacitor C21 is grounded.

[0041] +BUS is the bus power supply of the DC converter, resistor R17 is used to limit current, C12 is used as energy storage capacitor, and the two-way trigger diode D9 is a negative resistive switch; when the DC powe...

Embodiment 2

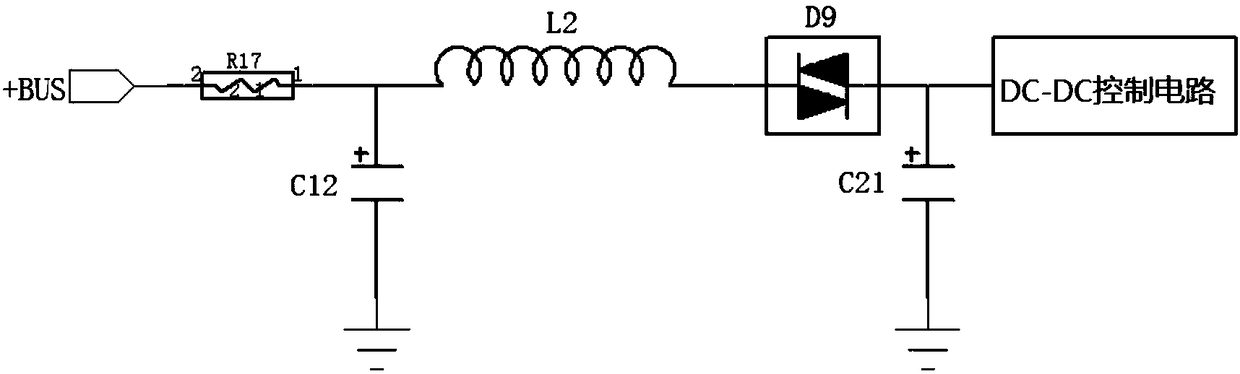

[0043] In this embodiment, an inductor L2 is added to the structure of Embodiment 1. Such as image 3 As shown, one end of the inductor L2 is connected to one end of the resistor R17 and the capacitor C12 respectively, and the other end of the inductor L2 is connected to one end of the bidirectional trigger diode D9. The inductance L2 is used to increase the Q value of the circuit when the two-way trigger diode D9 is turned on and to suppress the current rise speed, so that the current at the trigger time will not be too large and the two-way trigger diode D9 will be burned out, and the current is smoother. The impact of each device will also be greatly reduced.

Embodiment 3

[0045] In this embodiment, a Zener diode ZD1 is added to the structure of Embodiment 2. Such as Figure 4 As shown, one end of the Zener diode ZD1 is respectively connected to the other end of the resistor R17, one end of the capacitor C12, and one end of the inductor L2, and the other end of the Zener diode ZD1 is grounded. The zener diode ZD1 is used to make the two-way trigger diode D9 lose the trigger condition after the converter starts successfully, so as to protect the two-way trigger diode D9, and also can protect the energy storage capacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com