Wear resistance testing equipment for wheel rubber for automobiles

A technology of wear resistance and testing equipment, which is applied in the direction of testing wear resistance, measuring devices, strength characteristics, etc., can solve the problems of people around, inflexible hands, easy to be injured by tools, etc., and achieve the effect of avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

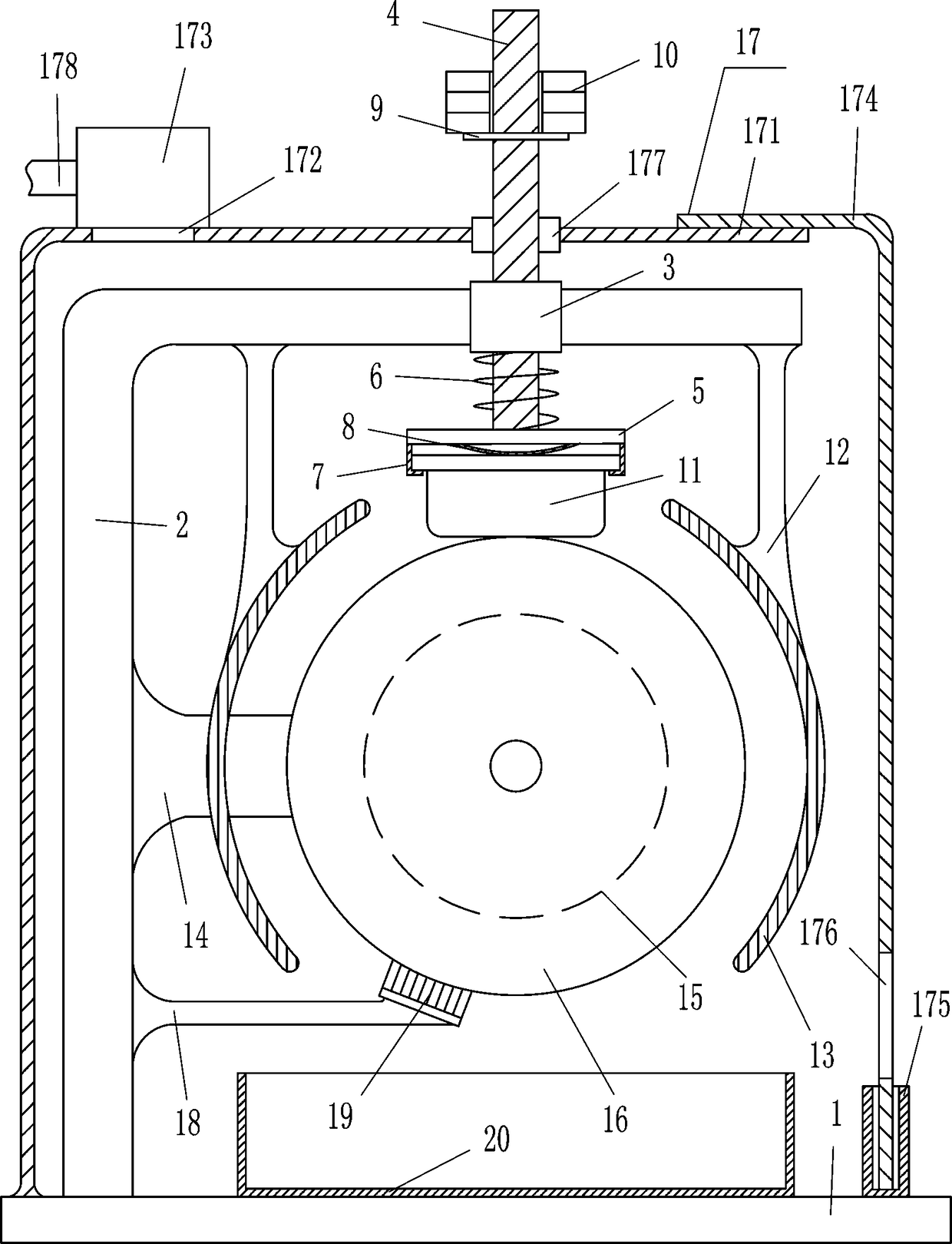

[0016] A kind of equipment for testing the wear resistance of automobile wheel rubber, such as figure 1 As shown, it includes a base plate 1, a 7-shaped rod 2, a guide sleeve 3, a guide rod 4, a horizontal plate 5, a first spring 6, an L-shaped plate 7, an elastic sheet 8, a fixed plate 9, a weight 10, and a vertical rod 12 , arc baffle plate 13, cross bar 14, driving motor 15 and grinding wheel 16, base plate 1 top left side is equipped with 7 type bar 2, and 7 type bar 2 inner left side middle part is equipped with cross bar 14, and cross bar 14 right ends A drive motor 15 is installed, and the output shaft of the drive motor 15 is connected with a grinding wheel 16 by a coupling, and vertical rods 12 are installed on the left and right sides of the top, left and right sides of the 7-type rod 2, and arcs are installed on the left and right sides of the vertical rods 12 bottom ends. Shaped baffle plate 13, arc-shaped baffle plate 13 is positioned at grinding wheel 16 left and...

Embodiment 2

[0018] A kind of equipment for testing the wear resistance of automobile wheel rubber, such as figure 1 As shown, it includes a base plate 1, a 7-shaped rod 2, a guide sleeve 3, a guide rod 4, a horizontal plate 5, a first spring 6, an L-shaped plate 7, an elastic sheet 8, a fixed plate 9, a weight 10, and a vertical rod 12 , arc baffle plate 13, cross bar 14, driving motor 15 and grinding wheel 16, base plate 1 top left side is equipped with 7 type bar 2, and 7 type bar 2 inner left side middle part is equipped with cross bar 14, and cross bar 14 right ends A drive motor 15 is installed, and the output shaft of the drive motor 15 is connected with a grinding wheel 16 by a coupling, and vertical rods 12 are installed on the left and right sides of the top, left and right sides of the 7-type rod 2, and arcs are installed on the left and right sides of the vertical rods 12 bottom ends. Shaped baffle plate 13, arc-shaped baffle plate 13 is positioned at grinding wheel 16 left and...

Embodiment 3

[0021] A kind of equipment for testing the wear resistance of automobile wheel rubber, such as figure 1 As shown, it includes a base plate 1, a 7-shaped rod 2, a guide sleeve 3, a guide rod 4, a horizontal plate 5, a first spring 6, an L-shaped plate 7, an elastic sheet 8, a fixed plate 9, a weight 10, and a vertical rod 12 , arc baffle plate 13, cross bar 14, driving motor 15 and grinding wheel 16, base plate 1 top left side is equipped with 7 type bar 2, and 7 type bar 2 inner left side middle part is equipped with cross bar 14, and cross bar 14 right ends A drive motor 15 is installed, and the output shaft of the drive motor 15 is connected with a grinding wheel 16 by a coupling, and vertical rods 12 are installed on the left and right sides of the top, left and right sides of the 7-type rod 2, and arcs are installed on the left and right sides of the vertical rods 12 bottom ends. Shaped baffle plate 13, arc-shaped baffle plate 13 is positioned at grinding wheel 16 left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com