Two-dimensional gradient porosity composite capillary core and preparation method thereof

A two-dimensional gradient and capillary core technology, applied in the field of heat pipes, can solve problems such as only applicable, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

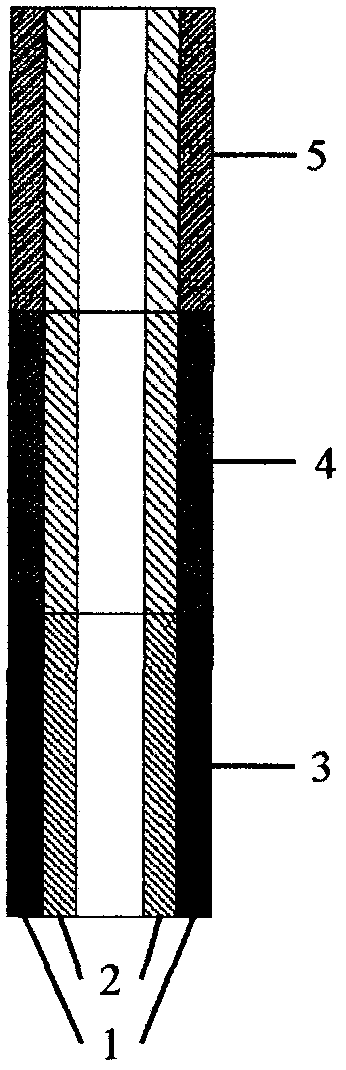

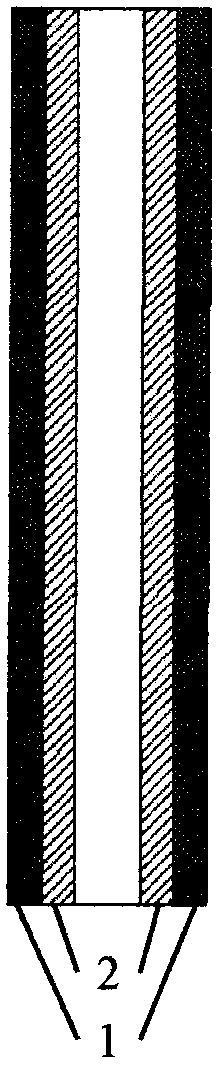

[0022] Such as figure 1 As shown, the present invention provides a novel two-dimensional gradient pore composite capillary core, including an inner layer and an outer layer with a pore gradient g1 in the radial direction, and an axial layer and an axial second layer with a pore gradient g2 in the axial direction. Layers and axial three layers, wherein, g1 and g2 can be set according to actual needs (the number of layers in the radial and axial directions can also be set according to actual needs). The schematic diagram of the cross-sectional structure of the traditional one-dimensional gradient pore composite capillary core is as follows: figure 2 As shown, it only has a pore gradient between the inner layer and the outer layer, but there is no pore gradient in the axial direction.

[0023] When preparing the above-mentioned new two-dimensional gradient pore composite capillary core, powder metallurgy and methods are used in combination with pore-forming agent technology. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com