Arch tires for lining masonry of industrial furnace pipe tee and construction method of tee masonry

An industrial furnace and inner lining technology, applied in the direction of lining repair, etc., can solve the problems of limited viewing angle, affecting processing quality, low construction efficiency, etc., and achieve the effects of avoiding oppression, improving masonry efficiency, and increasing construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

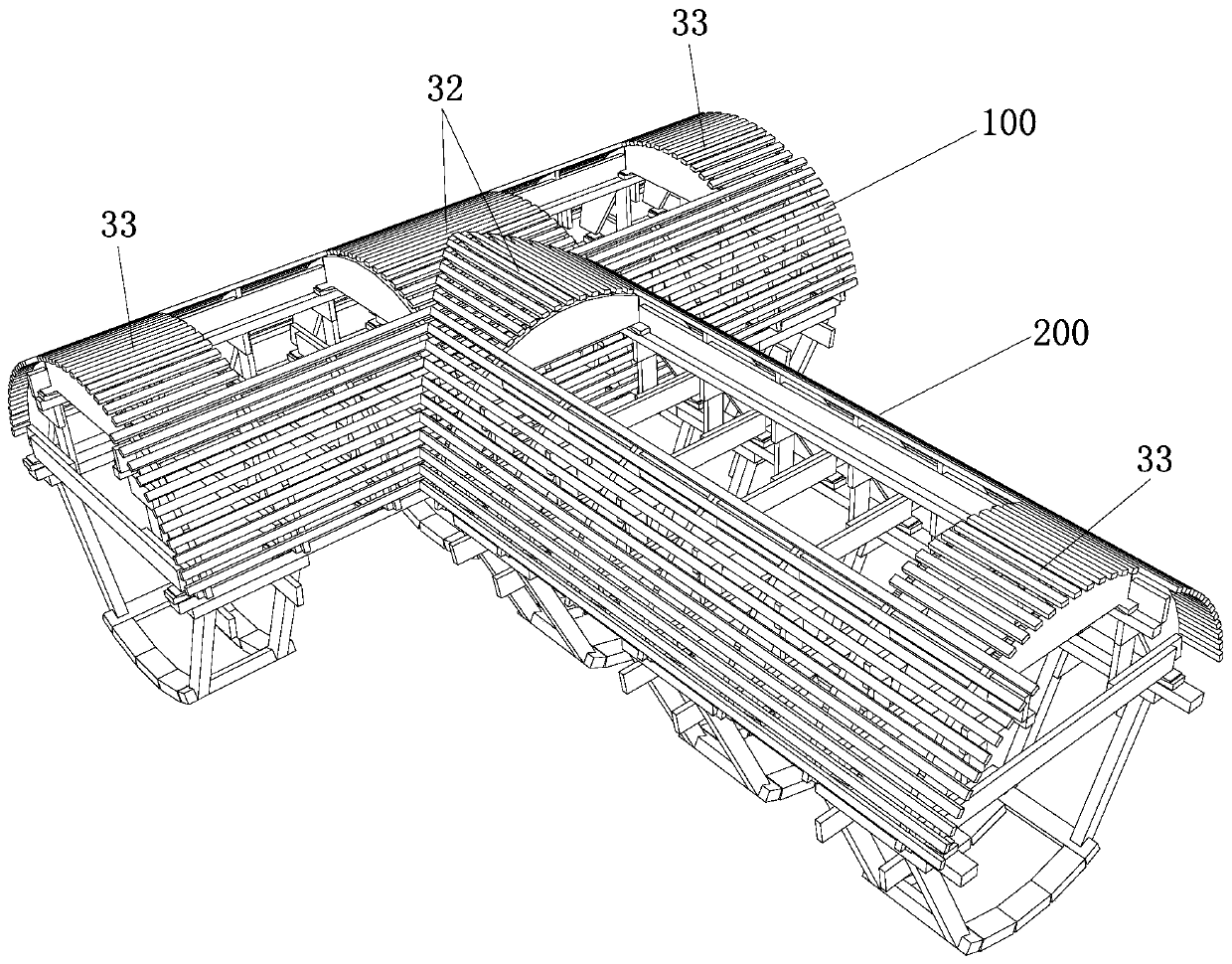

[0038] Such as figure 1Shown is a preferred embodiment of an industrial furnace pipe tee lining masonry tire, including a main pipe tire 100 and a branch pipe tire 200 that are perpendicular to each other and connected to each other.

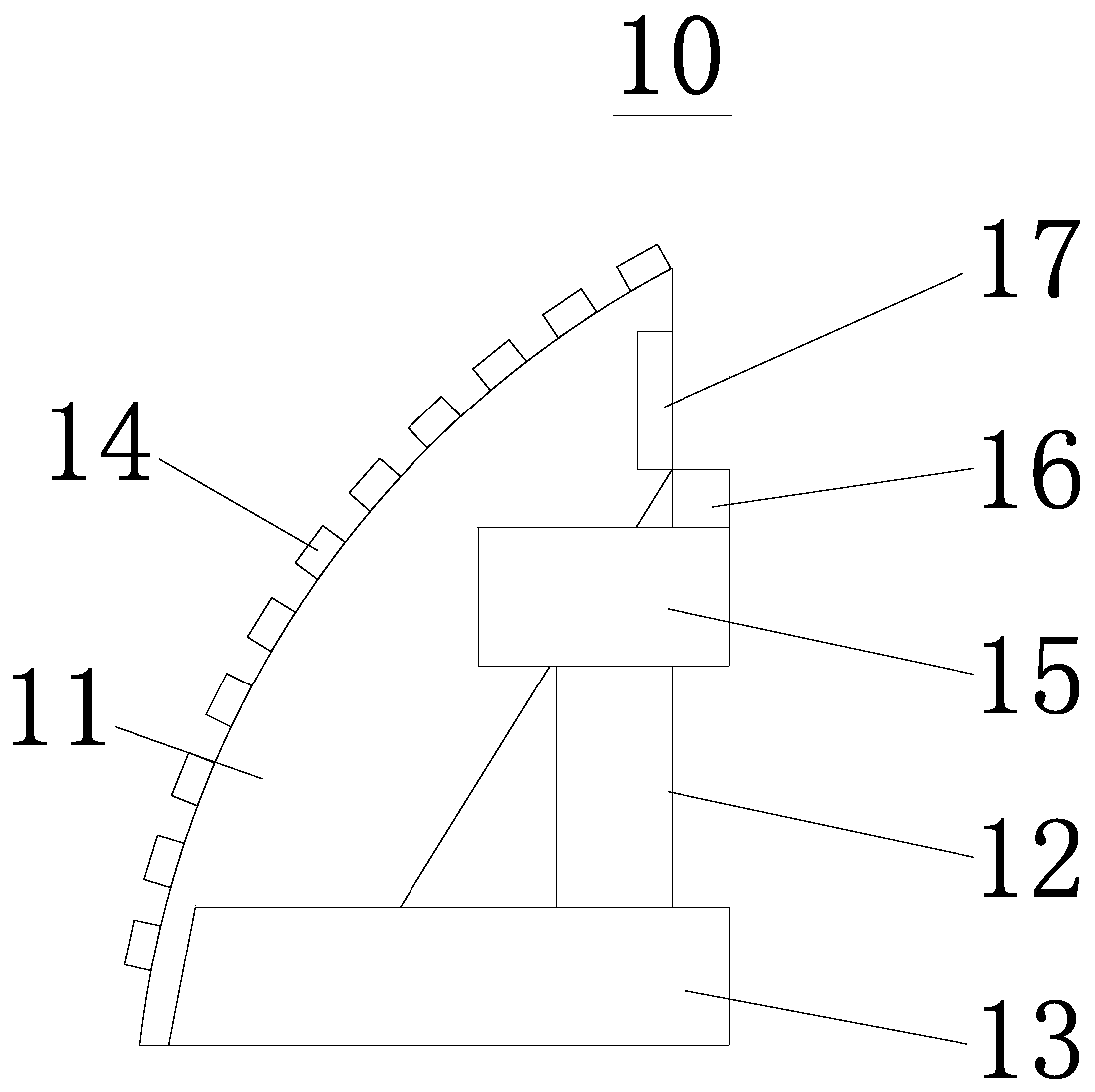

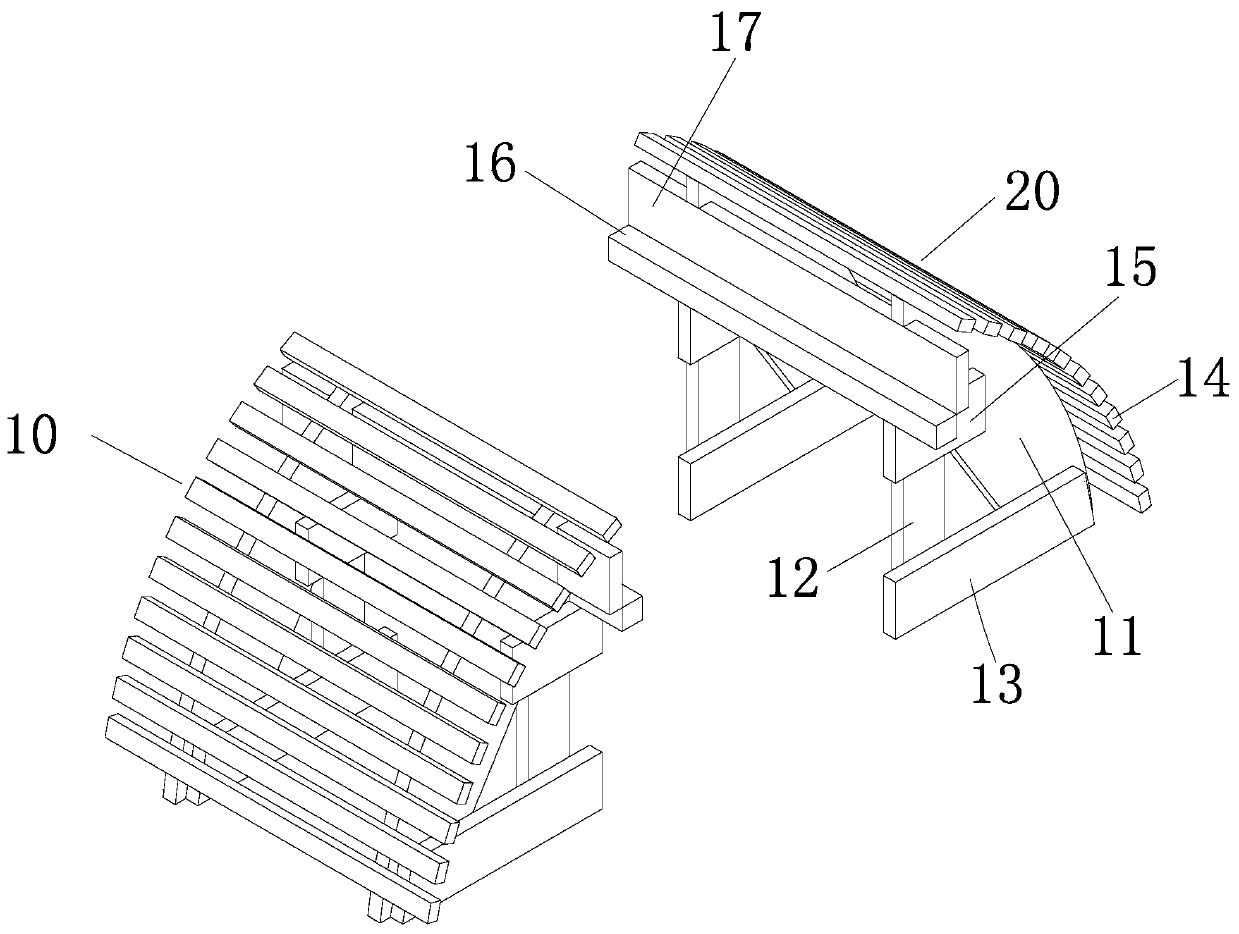

[0039] Such as Figure 2-7 shown, combined with figure 1 , The main pipe tire 100 includes a left valve tire 10 , a right valve tire 20 , a middle tire 30 and a tire support frame 50 . The left valve arch tire 10 comprises a tire strip 14 and some lower arc plates 11, the lower arc plates 11 are flat plates, one side of the flat plate is arc-shaped, the tire strips 14 are fixedly mounted on some lower arc plates 11, and some lower arc plates 11 Arranged evenly along the length directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com