Evaporator and application thereof in heat pump unit

A technology for evaporators and heat exchange tubes, applied in the field of evaporators assembled by non-welding technology, can solve problems such as medium leakage, achieve the effect of reducing welding quality requirements, reducing welding requirements, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

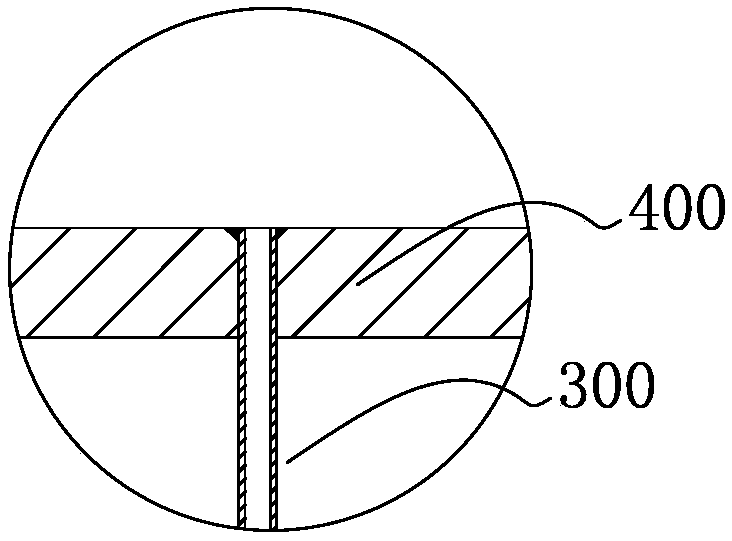

Embodiment 2

[0059] refer to Figure 6 , the end of the stainless steel tube 300 is expanded. After the expansion, a large end 310 with a length slightly greater than 2 times the thickness of the tube sheet is formed at both ends of the stainless steel tube. The round hole on the tube sheet 400 corresponds to the expanded hole. Dimensions and other installation steps are basically the same as in Embodiment 1. Before tightening the outer fastening nut, add a step, that is, insert a stainless steel sleeve 600 with tens of degrees below zero into the expansion part, and the specification of the stainless steel sleeve is the same as that of the stainless steel pipe After the sleeve is inserted, tighten the fastening nut. After tightening, the stainless steel sleeve 600 will heat up, and the expansion end of the heat exchange tube can be tightened from the inside. At the same time, the expansion part of the thin wall can be effectively avoided. Local deformation occurs under the locking action ...

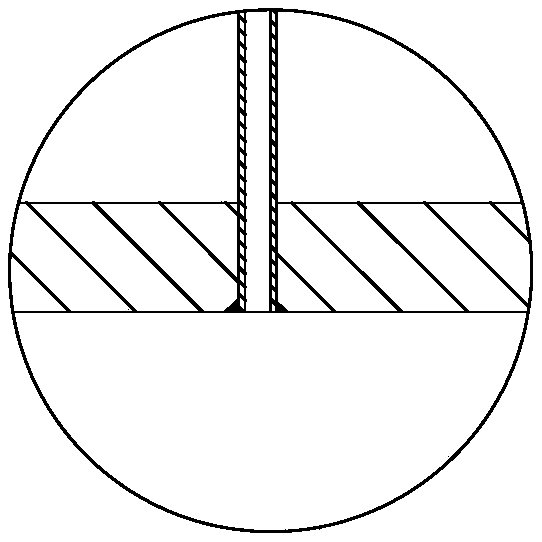

Embodiment 3

[0061] refer to Figure 7 , on the basis of Embodiment 1, for the deformation and technical extension of Embodiment 2, a stainless steel sleeve 600 is added, and the end of the stainless steel sleeve has a disc. After the fastening nut is tightened, the stainless steel sleeve is welded Welding, that is, welding connection between the stainless steel sleeve 600 and the fastening nut 530 can increase the loosening capacity of the fastening nut after welding. At the same time, the ends of the heat exchange tubes are limited to prevent axial serial movement.

Embodiment 4

[0063] In the above three embodiments, the above-mentioned stainless steel pipe is a straight pipe, that is to say, a pipe that is straight up and down. In this embodiment, in order to increase the heat exchange effect, the middle part of the heat exchange tube 300 is spirally wound to form a spiral tube 320 in the middle and straight tubes 330 at both ends. Refer to Figure 8 , where the straight pipe part can also form an enlarged end after expanding the hole. During operation, under the thermal expansion and contraction effect of the heat exchange tube, the deformation of the spiral tube itself can avoid the stress of relative sliding between the heat exchange tube and the conical seal, ensuring that the seal is in the best state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com