Low NOx gas burner based on internal recycle of gas and method of reducing emission

A gas burner and internal circulation technology, applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of reducing NOx emissions, weak swirl strength, and insufficient negative pressure, etc., to achieve long service life, Good working conditions and the effect of reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

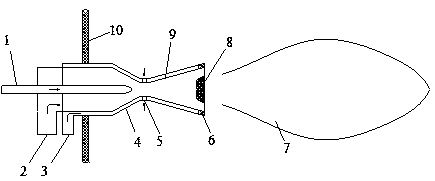

[0028] Such as figure 1 Shown, a low NO based on gas internal circulation x The gas burner includes a gas pipe 1, an inner secondary air passage 2, an outer secondary air passage 3, and an outer secondary air passage 3 outside the inner secondary air passage 2. The exit of the inner secondary air passage 2 and the outer secondary air passage 3 is provided with a stabilizing plate 8, and the flame 7 is sprayed from the stabilizing plate 8. The stabilizing plate 8 is made of heat-resistant steel.

[0029] Among them, the inner secondary air passage 2 is composed of an inner secondary air inlet pipe section and an inner Venturi type converging tube pipe section 9. The outer secondary air passage 3 is composed of an outer secondary air inlet pipe section and an outer Venturi type converging tube pipe section 4. The secondary air in the outer secondary air passage 3 has a cooling effect on the entire burner, and the burner has good working conditions and long service life. The left ...

Embodiment 2

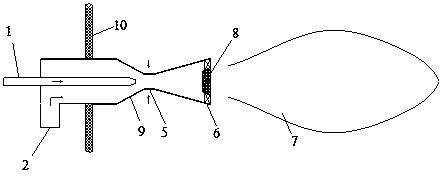

[0039] Such as figure 2 As shown, the present invention can be further modified to simplify the secondary air channel into one channel (that is, the inner secondary air channel and the outer secondary air channel in Embodiment 1 are simplified into one channel). The existence of the venturi converging tube section of the burner can still produce a strong flue gas recirculation effect, and can also produce a strong NOx emission reduction effect. This kind of implementation case is mainly suitable for burners with lower power and less gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com