Coal mine working face top plate high position directional drill hole group pressure relief gas extraction method

A coal mining face and directional drilling technology, which is applied in directional drilling, gas discharge, mining equipment, etc., can solve the problem that gas drainage is difficult to achieve resource utilization, construction conditions are affected by topography, and the extension of drilling trajectory cannot be guaranteed Real-time controllable drilling trajectory, significant economic and social benefits, and good governance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

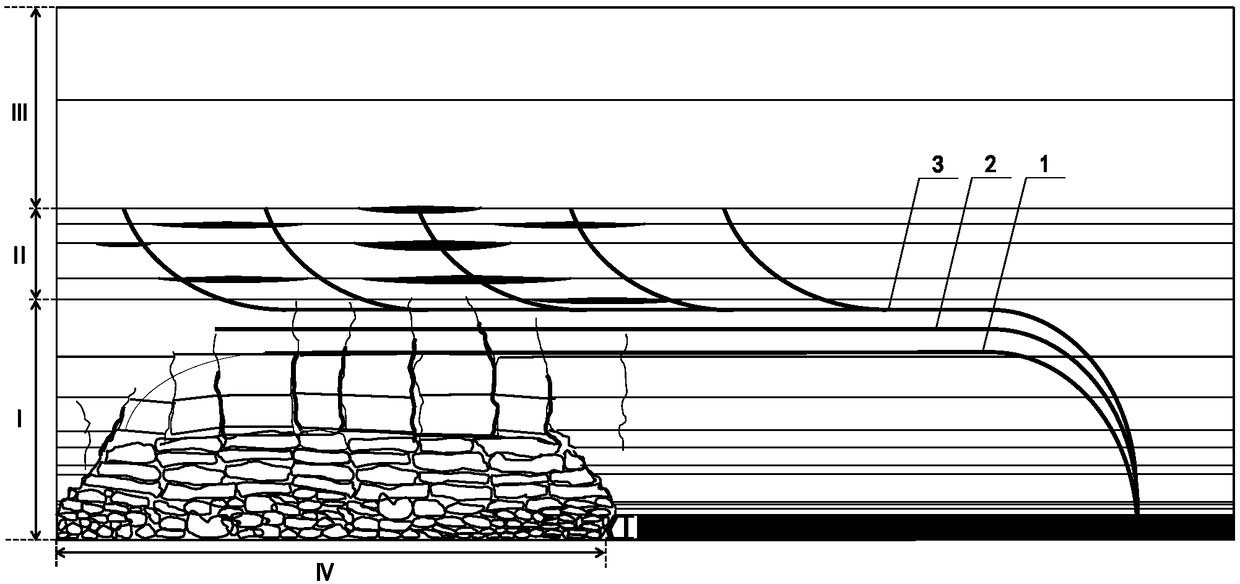

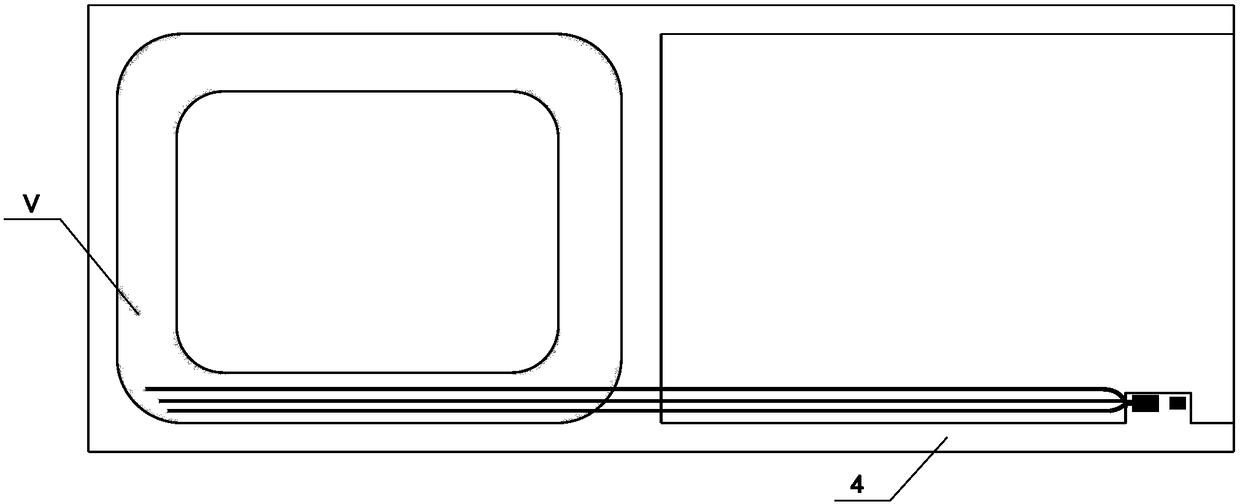

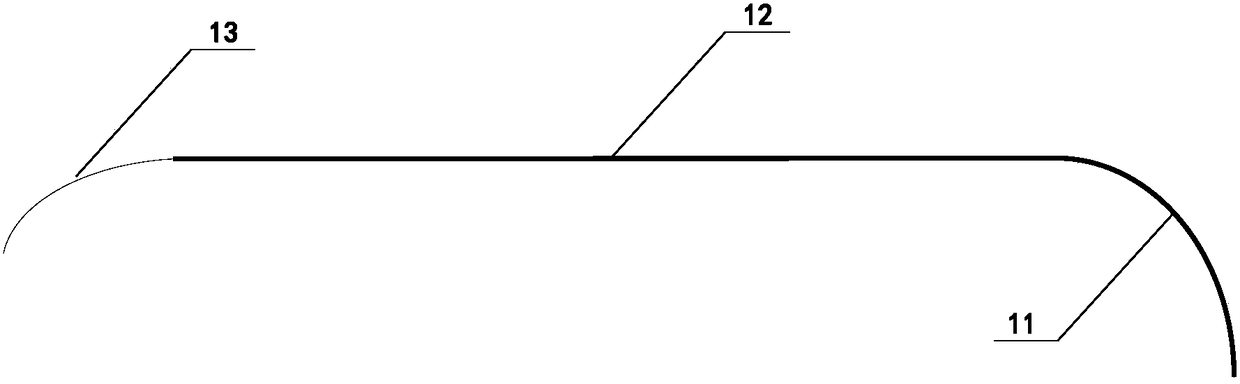

[0034] Such as figure 1 , 2 According to the characteristics of pressure relief, desorption and migration of gas, the overlying rock mass in goaf IV of the working face can be divided into three parts in the vertical direction: gas-conducting fracture zone I, pressure relief and desorption zone II, and difficult desorption zone III , the air-conducting fracture zone I near the middle of the goaf will be re-compacted as the working face pushes forward, and there is still an "O" ring fracture zone V around the goaf due to the support of the coal wall . The main hole section of the high-level drilling group is arranged in the "O" ring fracture zone V, and reaches the pressure relief and desorption zone II through the upwardly penetrated branch holes.

[0035] In this embodiment, before the mining of the coal mining face, on the basis of understanding the roof strata of the working face, the vertical stress concentration factor of 0.3 at the boundary of the goaf of the working f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com